What Makes a High-Quality Diamond Polishing Pad Supplier

When it comes to diamond polishing pads, quality isn’t just a luxury; it’s a necessity. Whether you’re polishing granite, marble, concrete, or any other stone surface, the right polishing pad can make all the difference. But how do you separate the great suppliers from the mediocre ones? What are the key factors that define a high-quality diamond polishing pad supplier? Let’s take a closer look.

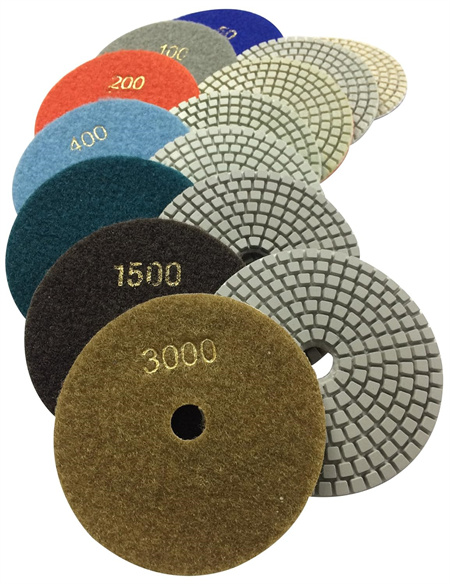

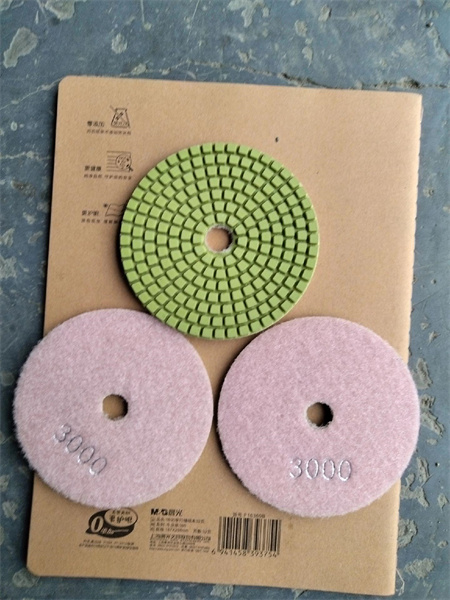

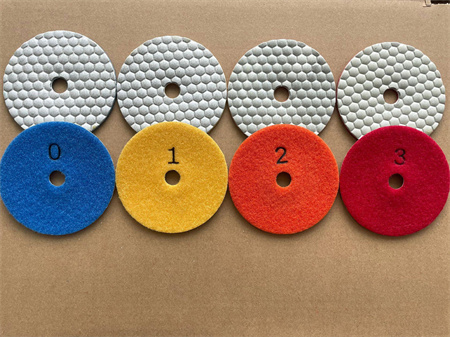

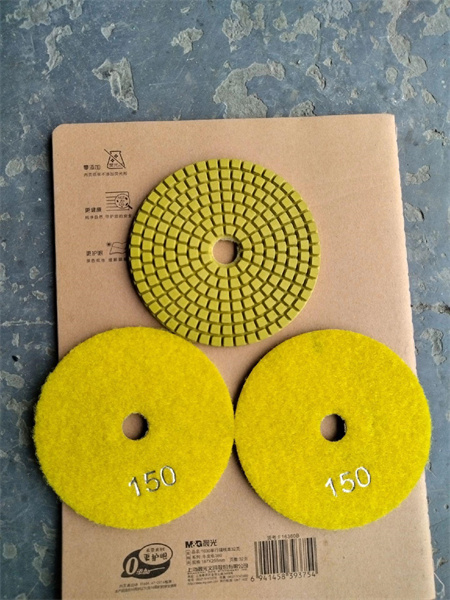

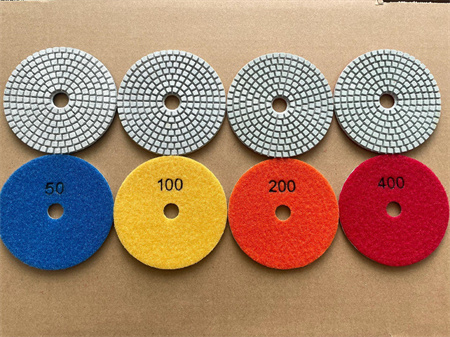

A supplier who understands the nuances of different surfaces and applications is also a hallmark of quality. Diamond polishing pads are not a one-size-fits-all solution. Different types of stone—granite, marble, concrete, and others—require different levels of abrasiveness and flexibility. A high-quality supplier will offer a range of options tailored to various applications, ensuring that their customers can find the right pad for their specific job. Whether it’s for heavy-duty grinding or delicate polishing, versatility in product offerings is key to meeting diverse customer needs.

Durability is another critical factor. Diamond polishing pads are known for their longevity, but not all pads are created equal. A good supplier offers pads that are built to last. This means the diamonds used in the pads must be of high quality and properly bonded to the pad itself. High-quality diamond polishing pads will withstand prolonged use without losing their effectiveness, even under the harshest conditions. A supplier who uses top-grade diamonds and invests in a strong bonding process will offer pads that offer superior performance over time.

Customer service is an often-overlooked but essential aspect of a great diamond polishing pad supplier. It’s not enough for a supplier to simply sell a product—they need to stand behind it. A high-quality supplier will offer excellent customer support, answering questions about product features, providing troubleshooting assistance, and addressing any issues that may arise during use. They understand that their customers are professionals relying on their products to get the job done right, and they take this responsibility seriously.

Moreover, pricing plays a significant role in selecting the right supplier. While high-quality pads might come with a higher price tag, a reputable supplier will offer fair and transparent pricing. They won’t charge inflated prices for subpar products, nor will they sacrifice quality to compete on price alone. Instead, they strike the right balance between cost and value, ensuring that customers receive the best return on investment.

Sustainability is becoming an increasingly important consideration as industries worldwide shift towards more eco-friendly practices. A high-quality diamond polishing pad supplier will be conscious of the environmental impact of their products. This might mean using sustainable materials in the manufacturing process or ensuring that their production methods are energy-efficient. In an era where environmental consciousness is critical, suppliers who take steps to reduce their carbon footprint are setting themselves apart.

Lastly, reputation matters. Word of mouth is powerful, and a supplier with a proven track record of providing high-quality diamond polishing pads will be well-regarded by industry professionals. Customer reviews, testimonials, and case studies all serve as indicators of a supplier’s reliability. A strong reputation often indicates that the supplier is trusted by its clients to deliver consistent results.

A great diamond polishing pad supplier doesn’t just provide a product; they provide a solution. They understand the demands of the industry and offer products that stand the test of time while delivering exceptional results. From innovation and versatility to durability and customer service, every aspect of their business should reflect a commitment to quality. By focusing on these factors, you can ensure that you’re partnering with a supplier who truly has your best interests at heart, helping you achieve flawless finishes every time.