Predictions for Diamond Tools in Architectural Projects

In the ever-evolving world of architecture, the tools that shape our structures are advancing at an incredible pace. One such tool, often revered for its strength and precision, is the diamond tool. Used in a range of applications from cutting to grinding, diamond tools have revolutionized the way architects and builders approach their projects. As we look toward the future, there are several key trends and predictions about how diamond tools will continue to influence architectural design and construction.

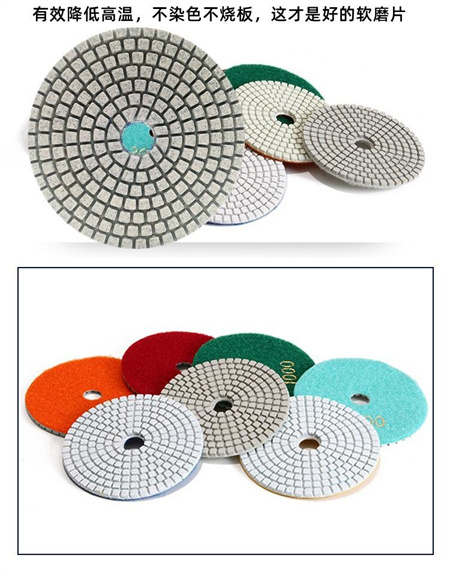

One major trend is the rise of smart and automated tools. The integration of smart technology into diamond tools is poised to make a significant impact. Imagine a cutting tool equipped with sensors that can measure the temperature and pressure in real-time, adjusting its speed and force for optimal performance. This not only extends the life of the tool but also ensures higher precision and efficiency in execution. For architects, the ability to fine-tune a tool’s performance to suit the specific material being worked on is a game-changer. It means less downtime, fewer mistakes, and more consistent results across large-scale projects.

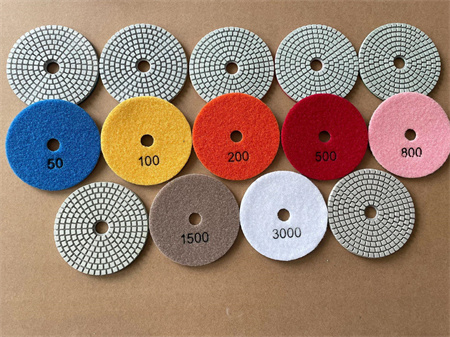

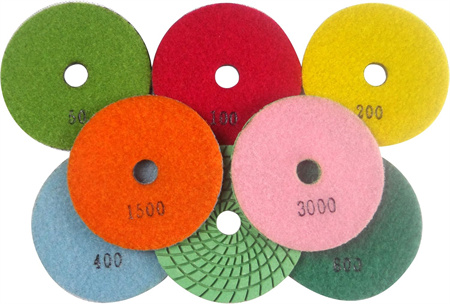

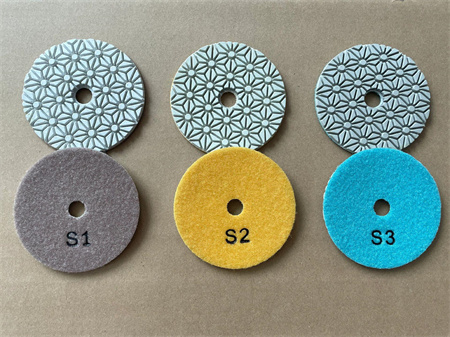

The development of specialized diamond tools is another trend that will shape the future of architecture. As architectural designs become more intricate, there is a growing need for tools that can handle specialized tasks with unparalleled accuracy. For example, diamond blades designed for cutting specific materials like ultra-high-performance concrete or glass can help achieve smoother, cleaner cuts. Similarly, diamond grinding tools are being refined to provide more consistent finishes on a variety of surfaces, from polished marble to rough granite. These tools are becoming more customizable, allowing architects and builders to select tools that are perfectly suited for each unique project.

One of the most promising aspects of diamond tool technology is its potential to enhance safety on construction sites. Modern diamond tools are designed with user safety in mind, featuring built-in safety features such as vibration reduction and dust suppression. As construction sites continue to adopt more rigorous safety standards, the role of diamond tools in reducing risks will become even more critical. With less dust and debris generated during cutting and grinding, there will be fewer health hazards for workers, and the overall safety of the site will improve.

Looking ahead, the future of diamond tools in architectural projects is undeniably bright. With advancements in smart technology, sustainability, specialization, and safety, these tools are becoming increasingly integral to the construction process. Architects and builders will be able to push the boundaries of what’s possible, creating structures that are not only functional and beautiful but also more efficient and environmentally responsible. As the construction industry continues to innovate, diamond tools will remain at the forefront, enabling new possibilities for design and construction. Whether it’s a towering skyscraper or a modernist home, the role of diamond tools in shaping the future of architecture is set to be more critical than ever.