The Ultimate Guide to Diamond Polishing Pads

When it comes to achieving a flawless finish on stone surfaces, diamond polishing pads are a game-changer. These high-performance tools are designed to make the job of polishing and refining various materials, such as marble, granite, concrete, and even glass, more efficient and effective than ever. Whether you’re a professional contractor or a DIY enthusiast, understanding the ins and outs of diamond polishing pads can drastically improve your results. This guide will walk you through everything you need to know about these powerful tools.

What Exactly Are Diamond Polishing Pads?

The beauty of diamond polishing pads lies in their versatility. They can be used on a variety of surfaces, including granite countertops, marble floors, concrete floors, and even glass. Whether you’re working on a large-scale commercial project or a smaller home renovation, diamond polishing pads are designed to deliver high-quality results every time.

How Do Diamond Polishing Pads Work?

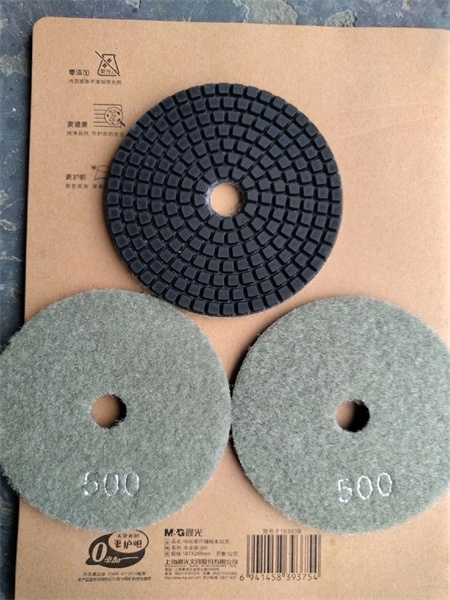

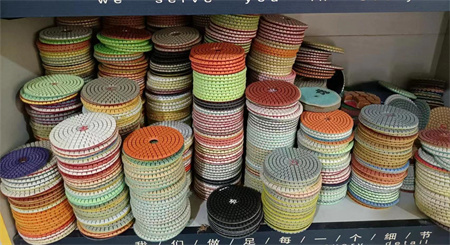

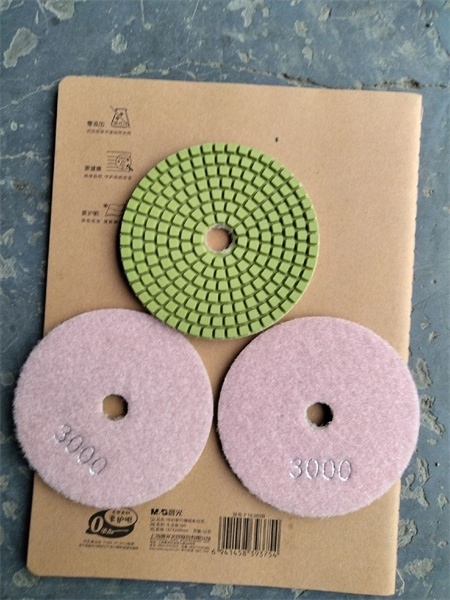

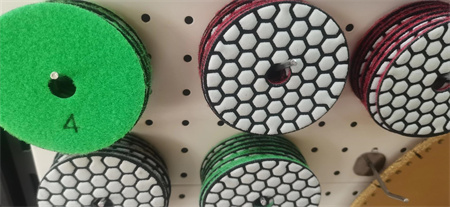

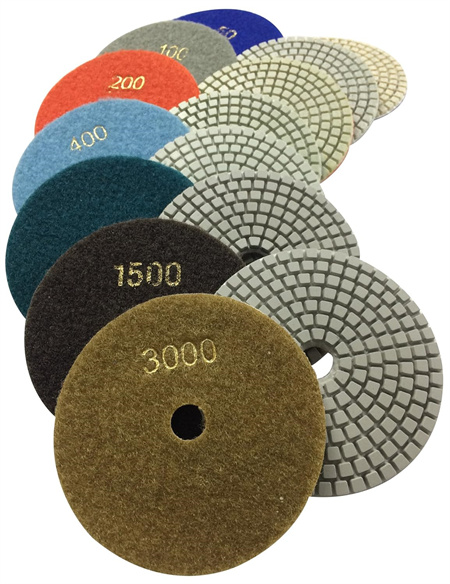

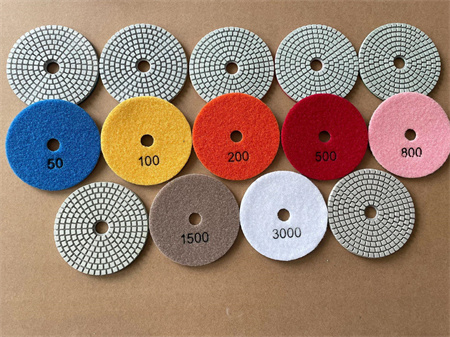

The pads typically come in a series of grits, with each grit level suited for a specific stage of the polishing process. The coarser grits (usually ranging from 50 to 400) are used for heavy grinding and removing deep scratches. As you progress to finer grits (from 800 to 3000 or even higher), the pad refines the surface, achieving a smoother and glossier finish.

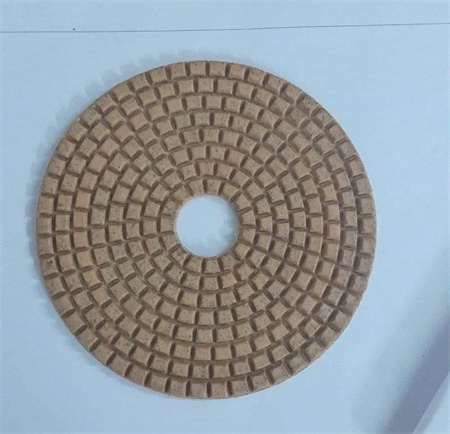

The process is fairly straightforward but requires patience and skill. It’s essential to move in consistent, circular motions when using diamond pads. Overlapping your strokes will ensure that the entire surface gets treated evenly, reducing the risk of streaks or uneven finishes. Water is typically used during polishing to help reduce heat buildup, as excessive heat can damage both the pad and the surface being polished.

Choosing the Right Diamond Polishing Pad for Your Project

Another factor to consider is the grit size. As mentioned earlier, the grit range is essential for the success of your project. If you’re starting with a rough, unfinished surface, begin with a coarse grit pad and work your way through finer pads. If you’re looking to give a surface a light touch-up, a finer grit might be all you need.

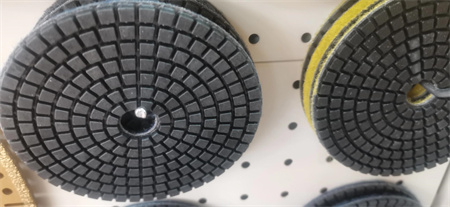

Resin-bonded diamond pads are commonly used for softer materials like marble and terrazzo, offering a smooth finish without excessive abrasion. For harder surfaces like granite or concrete, metal-bonded pads are usually the preferred option. These pads tend to last longer and are more aggressive, making them suitable for tougher jobs.

Benefits of Using Diamond Polishing Pads

One of the primary reasons diamond polishing pads have become so popular is their ability to provide high-quality finishes quickly and effectively. Whether you’re polishing floors, countertops, or intricate stone features, diamond pads cut down on labor time while ensuring a superior finish.

Additionally, these pads offer great durability. The diamonds themselves are extremely hard and wear-resistant, meaning your polishing pads will last far longer than traditional abrasive pads. This long lifespan results in better value for money, especially for professionals who need to rely on their tools for multiple projects.

Diamond polishing pads are also highly versatile. Their range of grits and the ability to work on different surfaces make them an essential tool for anyone in the stoneworking industry. They’re not just limited to traditional stone surfaces either—these pads can be used on concrete, glass, and even some metals, expanding the possibilities for a wide array of applications.

Maintaining Diamond Polishing Pads

To get the most out of your diamond polishing pads, proper care and maintenance are essential. After each use, rinse the pads thoroughly to remove any debris or particles that could damage the surface on your next job. Avoid letting the pads dry out after use; instead, store them in a cool, dry place to maintain their effectiveness.

If you’re using the pads on wet surfaces, make sure the water doesn’t get too dirty, as this could cause the pads to clog and lose their efficiency. For metal-bonded pads, occasional cleaning with a wire brush can help maintain their performance by removing any accumulated debris from the diamond segments.

Conclusion

Diamond polishing pads are a revolutionary tool in the world of stone and surface finishing. Their efficiency, durability, and ability to produce stunning results make them indispensable for anyone looking to achieve a high-quality polish on a variety of materials. With the right pad, proper technique, and a little patience, you can transform any surface into a gleaming masterpiece. Whether you’re polishing floors, countertops, or intricate stone features, diamond polishing pads will help you get the job done with precision and ease.