High-Performance Polishing Pads for Concrete Floors

One of the primary advantages of high-performance polishing pads is their efficiency in leveling the surface. Concrete floors often have a rough texture, cracks, or stains that require significant attention. Traditional grinding or polishing pads can be slow, leaving the surface uneven or unevenly polished. High-performance pads, on the other hand, are engineered to work faster and with more precision, ensuring that even the most challenging floors are smoothed out quickly without sacrificing quality. The result is a more even surface that not only looks better but also performs better under daily wear and tear.

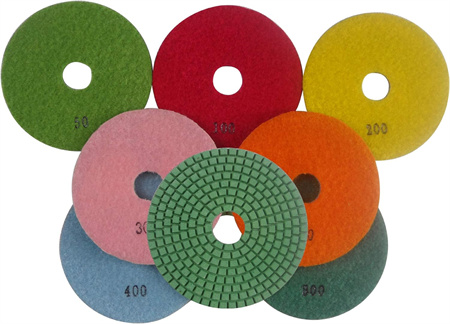

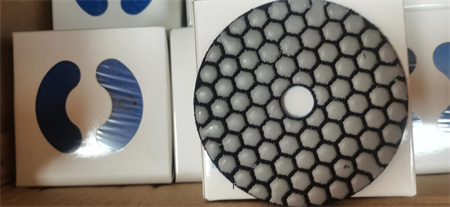

The choice of material is another factor that sets high-performance polishing pads apart. Many of these pads incorporate diamond abrasives, which are incredibly hard and capable of cutting through even the toughest concrete surfaces. Diamond pads are ideal for grinding and polishing because they can maintain their cutting power for extended periods, reducing the need for frequent replacements. The diamond abrasives are typically embedded within the pad, allowing for an even distribution of pressure and a consistent finish across the entire surface.

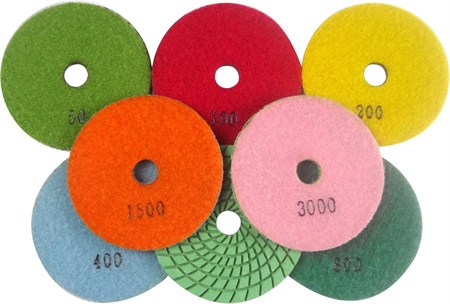

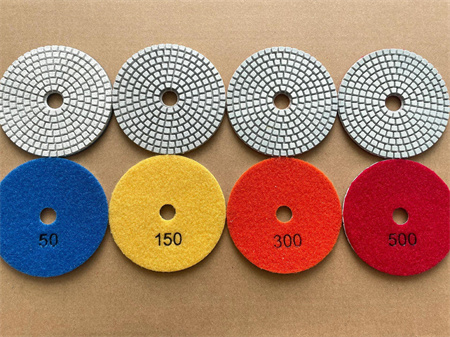

Another critical feature of high-performance polishing pads is their versatility. Depending on the desired finish, the pads can be used in various stages of the polishing process. For instance, during the initial grinding phase, a coarser grit pad is used to remove imperfections and flatten the surface. As the polishing process continues, finer grit pads are applied to bring out the shine. Some pads even have the ability to polish and hone concrete to a high gloss without the need for additional chemicals or waxes. This ability to achieve a desired finish without relying on harsh chemicals is a significant environmental and cost benefit, making these pads a preferred choice for many contractors.

Durability is another standout characteristic of high-performance polishing pads. Concrete floors are subject to heavy traffic, moisture, and physical impact, and a pad’s ability to withstand these conditions is crucial. High-performance pads are designed with long-lasting durability in mind, ensuring they can handle large-scale projects without deteriorating quickly. The combination of the robust materials and superior design ensures that these pads can maintain their performance across multiple uses, reducing overall maintenance costs.

As the demand for sustainable and low-maintenance flooring solutions grows, high-performance polishing pads also cater to this trend. With advancements in pad technology, manufacturers have developed pads that not only provide excellent results but also minimize environmental impact. These pads often use eco-friendly materials, and their efficient design reduces the amount of waste generated during the polishing process. By opting for high-performance polishing pads, both contractors and property owners can contribute to a more sustainable construction practice without compromising on quality or performance.

The impact of high-performance polishing pads on concrete floors goes beyond aesthetics. A well-polished floor is easier to clean and maintain, as the smooth surface doesn’t allow dirt, grime, or moisture to settle as easily. This makes the floor more hygienic and reduces the frequency of cleaning required. Additionally, the polished finish can enhance the overall lighting and ambiance of a room, creating a brighter and more spacious feel. These pads offer a cost-effective way to improve the look and functionality of concrete floors, making them a smart investment for both residential and commercial spaces.

In conclusion, high-performance polishing pads for concrete floors are indispensable for achieving flawless, long-lasting finishes. With their ability to level surfaces, reduce maintenance, and provide a wide range of finishes, they are an essential tool for anyone looking to elevate the look and feel of their concrete floors. Whether you’re a contractor working on a large commercial project or a homeowner updating your garage or basement, investing in high-quality polishing pads will make all the difference. With advancements in technology and design, these pads offer not only superior performance but also durability and sustainability, making them a top choice for modern concrete floor polishing.