If you’re in the market for high-quality diamond polishing pads, you’re in the right place. Our China-based factory specializes in manufacturing OEM diamond polishing pads that meet the needs of businesses and professionals across the globe. Whether you’re polishing granite, marble, or other types of stone, our pads are designed to provide outstanding performance and durability.

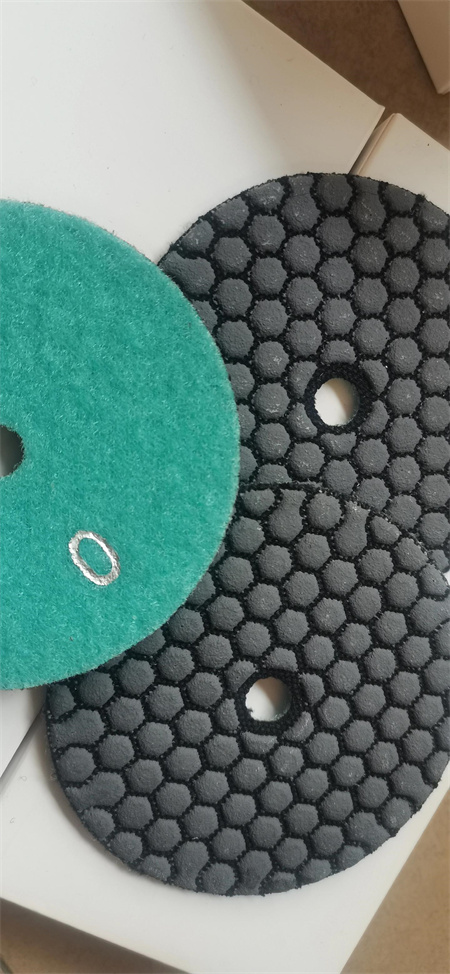

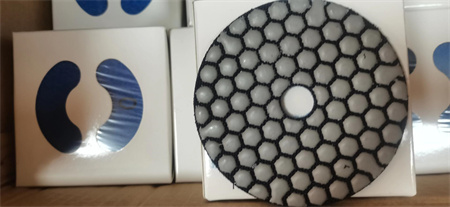

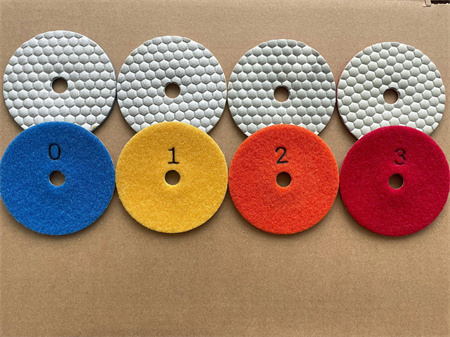

One of the standout features of our diamond polishing pads is their versatility. They are ideal for a range of applications, from floor polishing to countertop refinishing. The advanced diamond technology we use ensures a smoother finish with minimal effort, giving you a high-quality result every time. Plus, our pads are engineered to handle both dry and wet polishing methods, offering flexibility in different work environments.

In addition to their exceptional performance, these polishing pads are made with high-quality materials that extend their lifespan. We understand that durability is essential, and that’s why we use only the best materials to ensure long-lasting, reliable results. Whether you’re looking for a single pad or bulk orders, our products can handle high-volume use without compromising on quality.

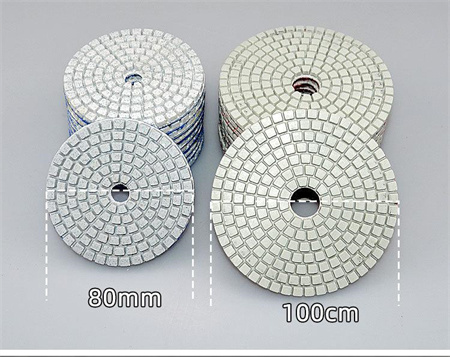

As a factory direct supplier, we can offer competitive pricing that you won’t find through middlemen. When you buy from us, you’re purchasing directly from the source, ensuring you get the best deal possible. We also offer custom OEM services, so you can get pads that are tailored to your specific requirements.

Our commitment to excellence is evident in every product we create. We understand that in the stone and concrete polishing industry, time is money. That’s why our diamond polishing pads are designed to get the job done faster while maintaining top-notch quality. Whether you’re in construction, home improvement, or any other industry that requires polishing, our pads will help you achieve a superior finish.

For businesses looking to streamline their operations and reduce costs, our diamond polishing pads are the perfect solution. With a strong focus on quality and customer satisfaction, we aim to be your go-to supplier for all your polishing pad needs. Trust us for all your diamond polishing pad requirements and experience the difference in quality, performance, and price.