How We Maintain Competitive Prices for Bulk Orders

At the heart of our business is a commitment to providing customers with the best value, especially when it comes to bulk orders. In today’s fast-paced market, finding a supplier that offers both high-quality products and competitive pricing can be a challenge. However, we believe that maintaining affordable prices doesn’t have to mean sacrificing quality. Here’s how we consistently keep our prices competitive without cutting corners.

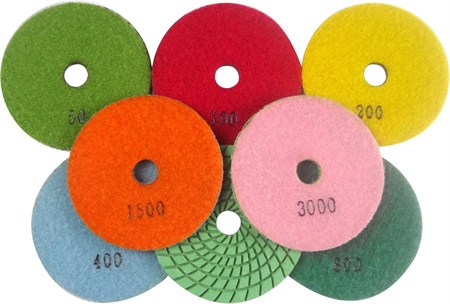

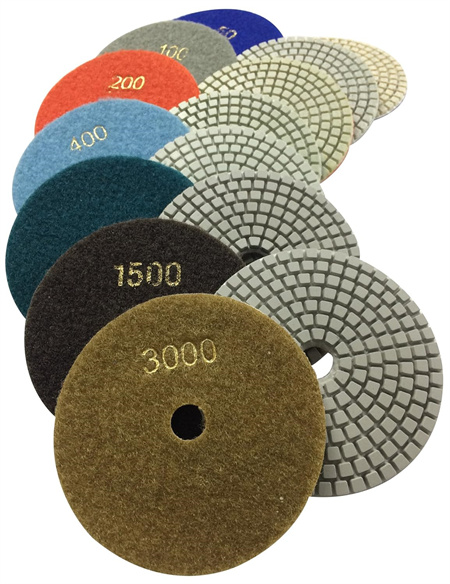

Our first and most important strategy is our strong relationships with suppliers. Over the years, we’ve built a network of trusted suppliers who share our commitment to quality and value. By negotiating long-term partnerships and bulk purchase agreements, we’re able to secure products at lower prices. These savings are passed directly to our customers. Instead of acting as a middleman, we work directly with manufacturers, which cuts down on extra costs and ensures that we can offer you the best possible price on large orders.

Efficiency is another key factor in how we maintain our competitive pricing. We continuously optimize our supply chain and production processes to reduce waste and improve productivity. Whether it’s through streamlining inventory management, using advanced software to track demand, or improving shipping logistics, we are always looking for ways to cut costs without sacrificing the quality or reliability of our service. This constant drive for efficiency means we can keep prices lower while maintaining the same high standards of product and customer service that our clients expect.

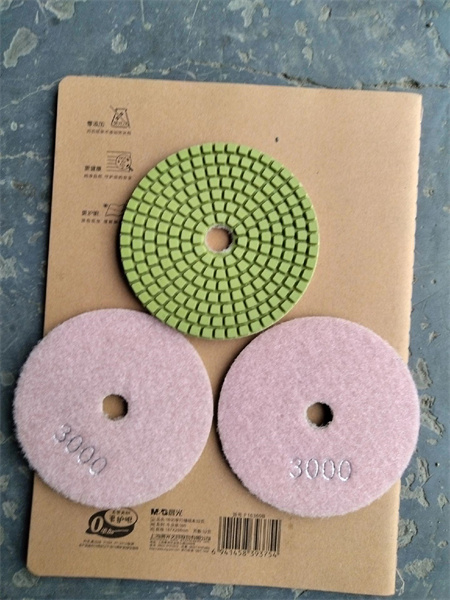

We also understand the importance of flexibility. Bulk orders can vary greatly in size, timing, and specific requirements, which means a one-size-fits-all approach to pricing just doesn’t work. We offer personalized quotes and customized pricing based on the unique needs of each customer. Our team works closely with clients to understand their purchasing goals and can adjust terms to suit their budget, whether they need a one-time order or are setting up a recurring supply agreement. This flexibility not only ensures competitive pricing but also strengthens our relationships with clients by providing tailored solutions.

In addition to the operational side, we leverage technology to keep our prices in check. By investing in the latest tools and software, we gain real-time insights into market trends and fluctuations in raw material prices. This data allows us to adjust our pricing strategies accordingly, ensuring that we’re always offering fair and competitive rates, even when the market is volatile. Our investment in technology also helps us stay ahead of the curve, anticipating changes in demand or potential supply chain disruptions that could impact prices.

Our commitment to competitive pricing is not just about numbers—it’s about building long-term partnerships with our clients. We understand that businesses need reliable, cost-effective solutions to thrive, and we work tirelessly to ensure that we are always offering the best possible prices for bulk orders. Our customers know that when they choose us, they are getting not only great products but also exceptional value and service.

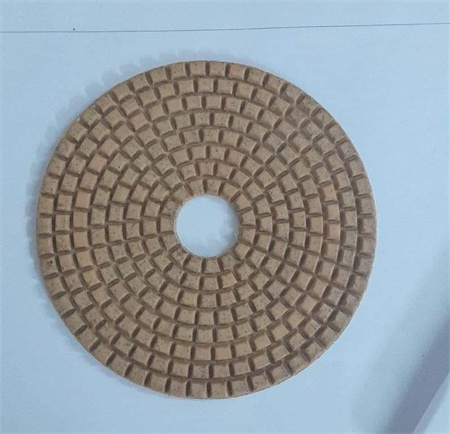

Of course, we never compromise on quality to achieve low prices. Each product we sell goes through a rigorous quality control process, ensuring that it meets our high standards. We understand that when you purchase in bulk, you expect consistency and reliability, and we pride ourselves on delivering that, every time. Maintaining quality while keeping costs low requires careful planning and attention to detail, and it’s something we take seriously.