How Our Pads Stand Out in Durability Tests

When it comes to choosing the right pad for your needs, durability is a non-negotiable factor. Whether you’re relying on them for heavy-duty tasks, long hours, or challenging environments, the last thing you want is to have your pads wear out too soon. That’s where we come in. Our pads are engineered not only for comfort and performance but also for unmatched durability. We put them through rigorous tests to ensure they stand the test of time, and here’s why they excel in ways others simply can’t match.

First off, our testing process is anything but ordinary. We push our pads to their absolute limits, simulating real-world conditions to see how they perform. From extreme heat to intense pressure, from high-impact scenarios to constant abrasion, our pads are subjected to conditions that mimic the harshest environments. We don’t just hope they will survive; we make sure they do. And the results? Our pads consistently outperform others in these critical durability tests.

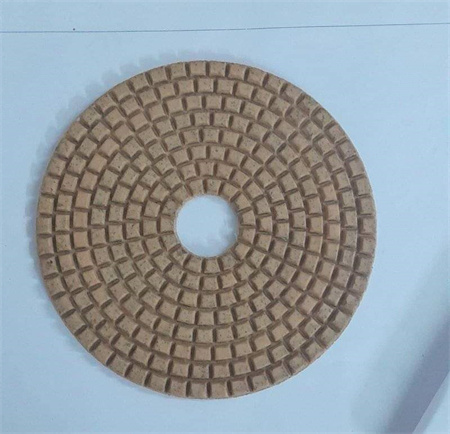

The surface of our pads is another area where we don’t cut corners. We use a high-density layer that resists abrasions, ensuring that no matter how much friction your pad encounters, it won’t break down or lose its integrity. Whether you’re walking, kneeling, or enduring prolonged pressure, the surface layer is built to stay intact, offering lasting protection without losing comfort. This is a major advantage over pads that tend to wear out quickly with everyday use.

In terms of pressure resistance, our pads don’t buckle under heavy loads. Whether you’re using them for construction, industrial applications, or sports, our pads retain their structural integrity even when exposed to intense pressure for extended periods. Unlike pads that flatten out or lose their cushioning effect, ours maintain their original shape, offering the kind of consistent comfort and protection you need to get the job done.

Testing for durability isn’t just about strength; it’s also about performance over time. That’s why we don’t just subject our pads to a few short tests. We put them through long-term stress tests, simulating years of use. This helps us understand how our pads hold up under continuous wear and tear, ensuring that they don’t deteriorate quickly or lose their effectiveness after extended use. The result is a product you can count on, day after day, year after year.

Customer feedback plays a crucial role in refining our durability standards. We constantly hear from users who rely on our pads in demanding environments, and their experiences help us improve our designs even further. It’s through this ongoing dialogue with our community that we’re able to stay ahead of the curve, continually evolving to meet the toughest demands.

So, whether you’re looking for a pad for personal use, industrial applications, or high-impact activities, you can rest assured that our products have been engineered to stand the test of time. After all, durability isn’t just a feature—it’s the foundation of everything we do.