Diamond Pad Polishing for Intricate Stone Designs

When it comes to crafting intricate stone designs, the finishing touch often makes all the difference. Whether you’re working with marble, granite, or other natural stones, the final polish can elevate a simple piece into a masterpiece. Diamond pad polishing has become a game-changer in this regard, offering superior results that traditional methods simply can’t match. But what exactly makes diamond pad polishing the go-to technique for achieving those perfect, high-gloss finishes on intricate stone surfaces?

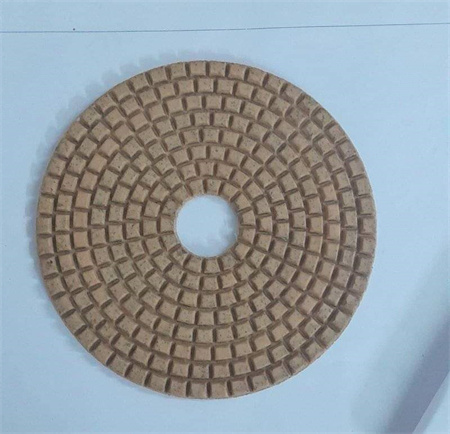

The secret lies in the diamond itself. Diamonds, known for their unparalleled hardness, are the perfect material for polishing stones, especially those with delicate carvings or complex patterns. Regular polishing tools often lack the precision needed to handle fine details, which can result in uneven finishes or, worse, damage to the stone. Diamond pads, on the other hand, provide the consistency and power needed to smooth out even the most detailed designs without compromising the stone’s integrity.

One of the biggest challenges when working with intricate stone designs is maintaining control over the polishing process. The risk of over-polishing or causing discoloration is ever-present, especially when dealing with softer stones or materials with intricate inlays. Diamond pad polishing minimizes these risks by offering a more controlled, gradual process. The diamond particles embedded in the pads work effectively to smooth the stone without generating excessive heat, which could lead to surface discoloration or warping.

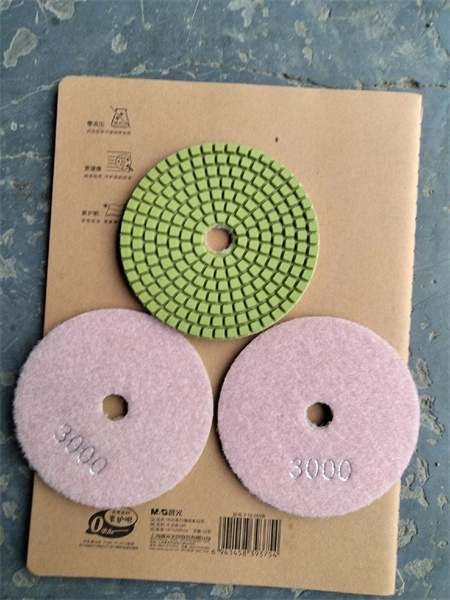

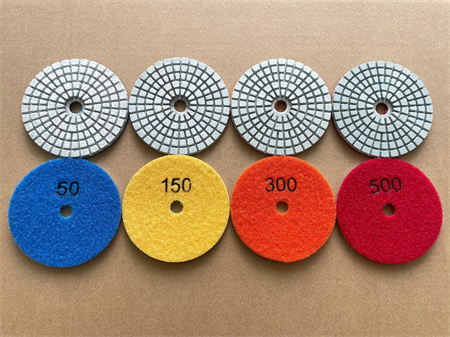

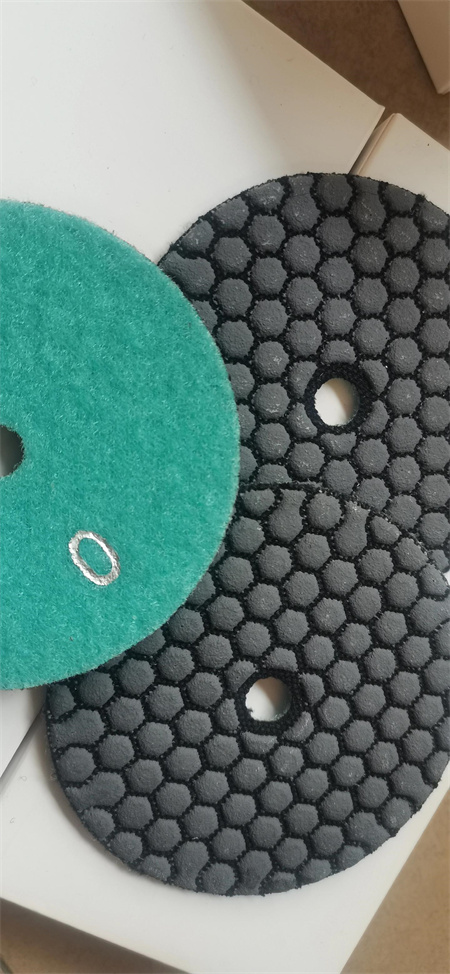

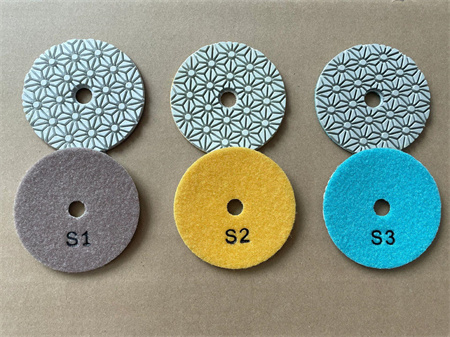

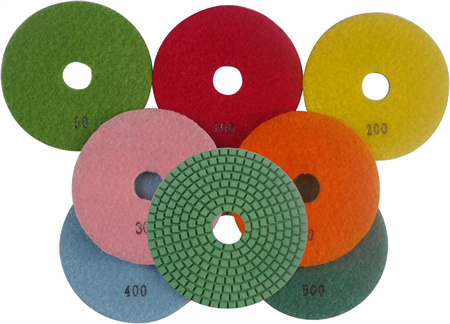

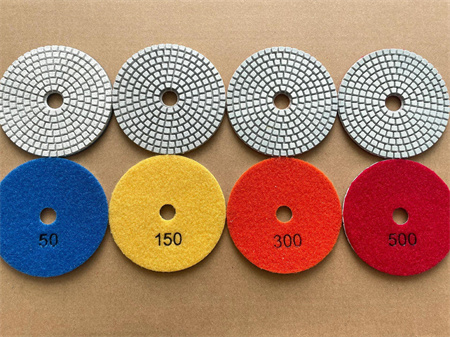

Furthermore, diamond pads can be used on a range of stone types and finishes, making them versatile tools for professionals and hobbyists alike. Whether it’s for creating intricate details on a kitchen countertop or refining the delicate surfaces of a stone sculpture, these pads can be adapted to different levels of intensity depending on the project’s requirements. With varying grits available, diamond pads can be used for everything from coarse grinding to achieving the ultra-smooth, high-gloss shine that sets off a stone’s natural beauty.

For craftsmen working with marble or granite, diamond pad polishing has proven to be especially beneficial. These stones are notoriously challenging to work with due to their hardness, and achieving a perfect, blemish-free surface can be difficult without the right equipment. By using diamond pads, artisans can tackle these tough materials with ease, ensuring a smooth, even finish without the risk of cracks or chips that can often occur with traditional polishing tools.

What’s more, the durability of diamond pads makes them a long-term investment. Unlike other polishing materials that wear down quickly, diamond pads maintain their effectiveness for much longer. This is particularly important for those who frequently work on stone surfaces and need a reliable, cost-effective polishing solution. The longevity of these pads reduces the need for constant replacements, saving both time and money in the long run.

The process of diamond pad polishing is not only practical, but it also gives artisans the opportunity to experiment with different textures and finishes. Depending on the type of grit and pressure used, craftsmen can create a variety of effects, from a soft, satin finish to a high-gloss, mirror-like shine. This versatility allows for greater creativity, enabling designers to bring their visions to life in ways that traditional methods simply can’t.

In addition to its precision and versatility, diamond pad polishing is also environmentally friendly. Unlike some other polishing techniques that rely on harsh chemicals or abrasives, diamond pads offer a more sustainable solution. The absence of toxic substances means that stone workers can produce beautiful finishes without compromising on health or environmental safety.

For anyone in the stoneworking industry or even DIY enthusiasts working on personal projects, the benefits of diamond pad polishing are undeniable. It’s a technique that combines precision, efficiency, and versatility, making it the ideal choice for achieving stunning results on even the most intricate stone designs. Whether you’re looking to refine the smallest details of a decorative stone or polish a large countertop, diamond pads provide the consistency and durability needed to get the job done right.