Avoiding Common Mistakes When Using Diamond Polishing Pads

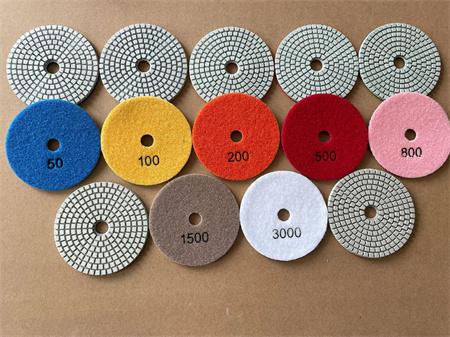

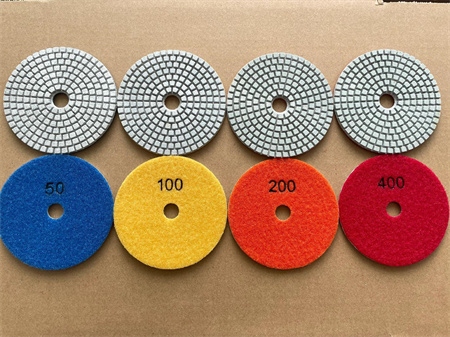

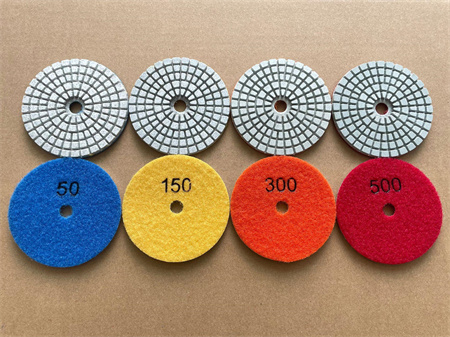

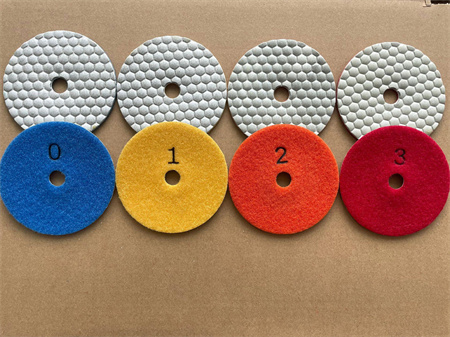

One of the biggest blunders people make is using the wrong grit for the task at hand. Diamond pads come in a range of grits, each suited to a specific stage of the polishing process. Starting with a pad that is too fine for a rough surface means you’ll spend far more time and energy than necessary, and the results may not be as effective. Conversely, jumping straight into a coarse grit on a delicate surface can leave unsightly scratches that are difficult to remove. For instance, when working with a highly polished marble countertop, it’s crucial to begin with a lower grit, gradually progressing to finer ones to get that mirror-like shine.

Speed is another area where mistakes commonly happen. Using the polishing machine at too high a speed can lead to a variety of issues, from uneven polishing to overheating the pads and even creating a hazy finish instead of a shiny one. While it might seem like a higher speed would get the job done faster, it’s important to let the pads work at their own pace. Each surface has a different texture and density, and rushing through the process will only compromise the quality of the finish. Slow, controlled movements with the correct speed will result in a smoother, more consistent outcome.

It’s also easy to overlook the importance of keeping the diamond polishing pads clean during use. As you work, small particles from the surface being polished will collect on the pad. These debris can cause the pad to become clogged, which can impede its ability to work efficiently. To avoid this, regularly rinse the pad or wipe it down to ensure it’s free of dirt or dust buildup. A clogged pad not only reduces the overall effectiveness of the polishing process but can also scratch the surface, undoing all your hard work.

One often-forgotten detail is proper pressure. Applying too much pressure to the pad is a surefire way to ruin your work. More pressure doesn’t necessarily lead to better results—it can actually cause the diamonds to wear out faster, distort the finish, and create uneven polishing. Instead, let the diamond particles do the work. Light, consistent pressure ensures even distribution of the abrasive material and helps extend the lifespan of both the pad and the surface you’re working on. This method also prevents unnecessary damage to the surface.

Lastly, it’s important not to rush through the process. Polishing a surface is an art that takes patience. Each stage, from coarse to fine, requires time and attention to detail to ensure that the final result is flawless. Skipping steps or cutting corners might save a bit of time upfront, but it’s likely to lead to problems down the road—whether it’s uneven finishes, surface damage, or an overall poor result. Be prepared to invest the necessary time into each step of the process for the best possible outcome.

Using diamond polishing pads might seem like a straightforward task, but there are several pitfalls to avoid. Understanding the importance of choosing the right grit, ensuring adequate lubrication, controlling speed and pressure, and keeping the pads clean are all critical for achieving a smooth, high-quality finish. By avoiding these common mistakes, you’ll be able to produce professional results while prolonging the life of your tools and ensuring the surface you’re working on remains in pristine condition. Take your time, use the right techniques, and you’ll be amazed at the glossy results you can achieve.