Best Diamond Pads for Polishing Granite Slabs

Granite slabs are an absolute masterpiece of nature, offering elegance and durability to any space. However, their polished shine is not something that happens overnight. It takes the right tools and techniques to bring out that glossy surface, and when it comes to achieving a professional-grade finish, diamond polishing pads are a must-have. These specialized pads are engineered to tackle the hardness of granite while delivering a smooth, mirror-like finish that brings out its full beauty.

When you’re looking to polish granite slabs, the first thing to consider is the quality of the diamond pads. Not all diamond pads are made the same, and selecting the right one can make a huge difference in both the efficiency of your work and the final result. So, let’s dive into what makes the best diamond pads for polishing granite slabs and why they’re the go-to tool for professionals.

Why Choose Diamond Pads for Granite?

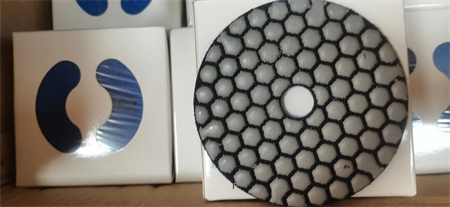

Granite is a dense, tough stone, and polishing it requires more than just your average abrasive pads. Diamond pads are designed specifically for hard stone surfaces, such as granite, quartz, marble, and concrete. The key feature that makes diamond pads ideal for granite polishing is the abrasive quality of diamond particles embedded within the pad itself. Unlike traditional sandpaper or steel wool, these pads can grind away rough surfaces, scratches, and imperfections while maintaining the integrity of the stone.

Diamond pads work by slowly grinding down the stone’s surface with finer grit levels, eventually revealing a smooth, high-gloss finish. They also offer significant advantages in terms of longevity. Due to the durability of diamonds, these pads can handle multiple polishing jobs without losing effectiveness, saving you both time and money in the long run.

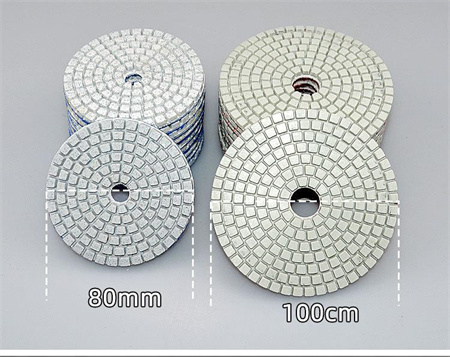

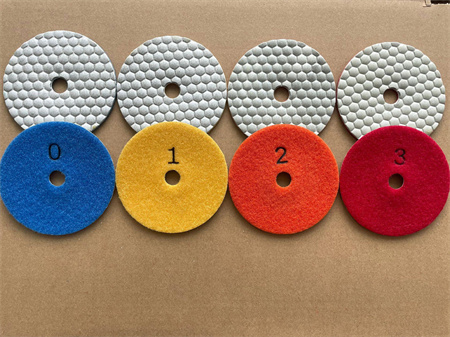

Types of Diamond Pads for Granite

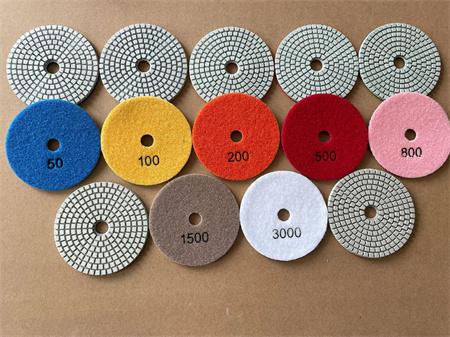

There are several types of diamond pads designed specifically for granite, each with its own purpose and benefits. These pads are often categorized by their grit level, ranging from coarse to ultra-fine. The finer the grit, the more polished the surface becomes. Here’s a breakdown of the typical grit levels you will find:

1. Coarse Diamond Pads (50-100 Grit): These pads are used for heavy-duty grinding and removal of deep scratches or imperfections. They are ideal for the initial stages of polishing, where you need to smooth out rough surfaces before proceeding to finer grits.

2. Medium Diamond Pads (200-400 Grit): After using the coarse pads, medium grit pads help further refine the surface and eliminate any smaller scratches left behind. These pads are excellent for preparing the stone for the finer polishing steps.

3. Fine Diamond Pads (800-1500 Grit): Fine grit pads are perfect for smoothing out the stone and beginning the polishing process. At this stage, your granite slab will start showing more of its natural sheen and luster.

4. Extra Fine Diamond Pads (3000-8000 Grit): These ultra-fine pads give the granite its mirror-like finish. Using these pads in the final polishing stages ensures the stone reflects light beautifully and achieves a glossy, high-end look.

Top Brands of Diamond Pads for Polishing Granite

When it comes to selecting the best diamond pads for polishing granite slabs, brand reputation and pad quality are key. Here are some of the top brands that professionals swear by:

– Flexovit: Known for its high-quality abrasives, Flexovit offers diamond pads that are specifically engineered for granite polishing. They are durable and efficient, providing a smooth finish with minimal wear.

– Diamond Tool Store: A favorite among stone fabricators, this brand provides a wide range of diamond pads in varying grit levels. Their pads are known for exceptional performance, whether you’re working on large granite surfaces or smaller countertop projects.

– MK Diamond: A trusted name in the stone polishing industry, MK Diamond offers some of the best diamond pads available. Their products are known for their long lifespan, superior cutting power, and consistent results.

– GranQuartz: If you’re looking for versatility and durability, GranQuartz diamond pads deliver outstanding results across a range of granite types. Their products provide excellent value for the price, making them a popular choice among both DIYers and professionals.

Choosing the Right Diamond Pad for Your Project

The right diamond pad depends on a few factors: the condition of your granite, the type of finish you want, and the tools you’re working with. For example, if your granite slab is brand new with minimal scratches, you can start with finer grit pads. However, if your stone is heavily damaged or you need to remove significant wear, you should begin with a coarser grit and gradually move up to finer ones.

Additionally, consider the machine you’re using to polish the granite. If you’re using a hand polisher or a wet polisher, make sure the pads you choose are compatible with the tool. Wet polishing can help reduce dust and improve the pad’s effectiveness, especially when dealing with granite’s dense surface.

How to Get the Best Results

For the best results, make sure you follow the proper polishing technique. It’s important to work in small sections, applying consistent pressure and ensuring each section is polished evenly before moving to the next. Always keep the surface wet to prevent overheating and to keep the dust down. Patience is key—polishing granite takes time, but the end result is worth the effort.

Conclusion

Diamond pads are the ultimate tool for polishing granite slabs, offering unmatched durability, efficiency, and results. By choosing the right pads for your project and working through the proper grit levels, you can restore your granite surfaces to their original beauty, whether you’re tackling a countertop or a large flooring installation. Investing in high-quality diamond pads will not only save you time but also help you achieve that flawless, glossy finish that makes granite so stunning. So, whether you’re a professional stoneworker or a DIY enthusiast, make sure you have the best diamond pads on hand to bring out the brilliance in your granite slabs.