Diamond Polish Pad Made in China for Granite Monument Importers

Granite monuments are timeless symbols of remembrance, and the process of bringing out the stone’s natural beauty requires precision. For importers of granite monuments, finding the right tools to enhance the shine and smoothness of the stone is crucial. That’s where the Diamond Polish Pad made in China comes in, offering an effective and affordable solution for polishing granite to a high-gloss finish.

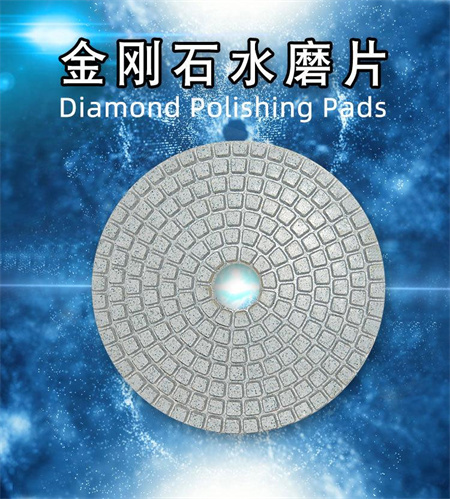

China has established itself as a global leader in the production of high-quality stone processing tools, and the diamond polish pads are no exception. These pads, crafted with precision, are designed to give granite monuments a mirror-like sheen, highlighting every detail of the stone’s intricate patterns. Whether you’re dealing with a large monument or a small decorative piece, these pads are versatile enough to handle various sizes and complexities.

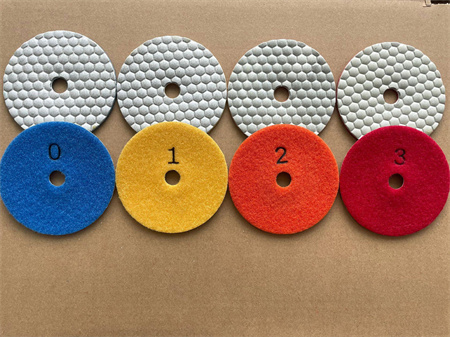

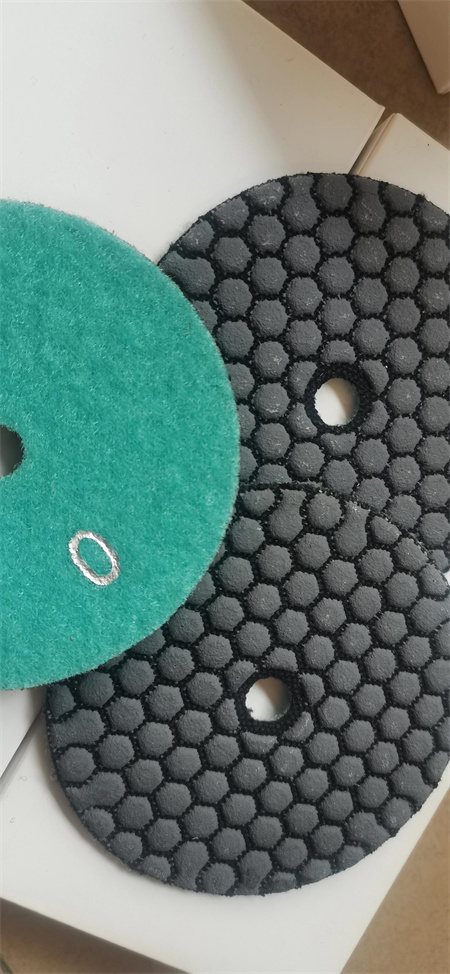

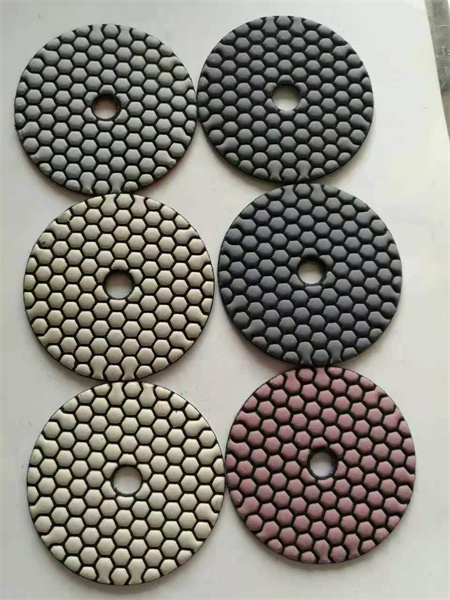

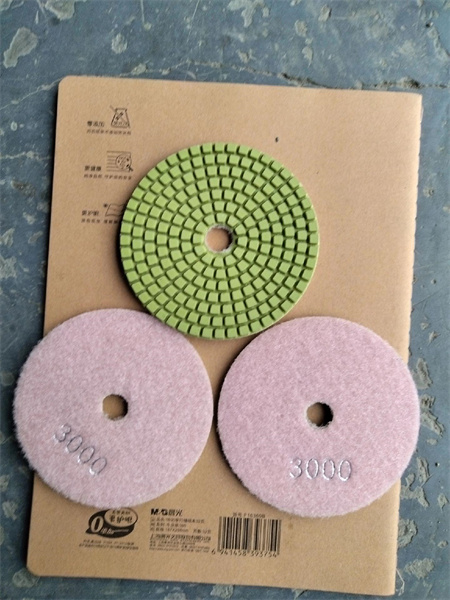

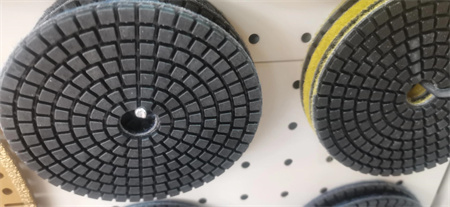

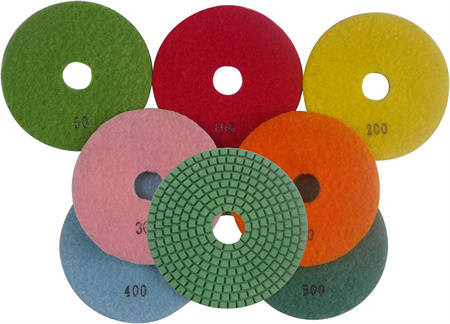

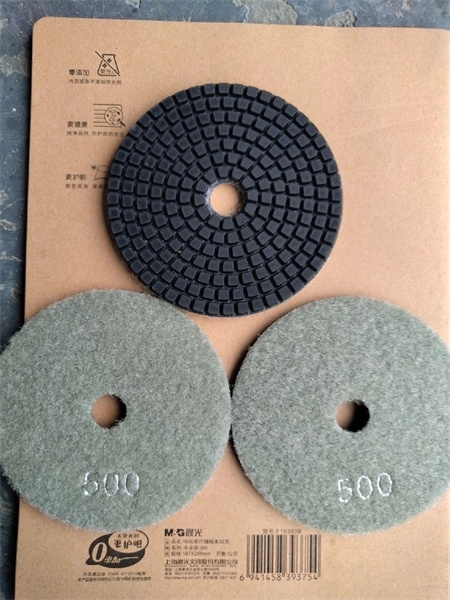

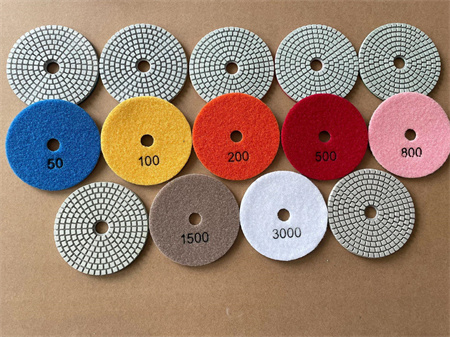

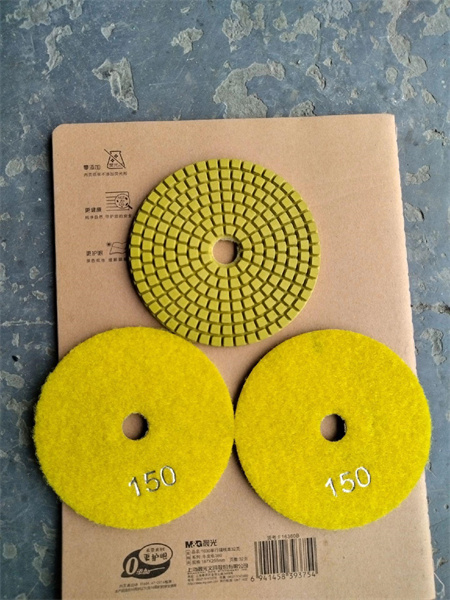

What sets the diamond polish pads apart is their durability. Made from high-quality diamonds embedded into a flexible yet sturdy base, these pads can withstand the demands of polishing granite without wearing down quickly. This makes them ideal for importers who need reliable tools that offer long-lasting performance at a competitive price. Plus, the consistency and uniformity of the polish ensure that each monument is treated with the same level of care and attention to detail.

When it comes to polishing granite, time is of the essence. Importers often need to turn around projects quickly, and the efficiency of the diamond polish pads ensures that the process is faster and more cost-effective. Unlike traditional polishing methods, these pads work seamlessly with polishing machines, reducing the amount of manual labor involved and speeding up production.

The flexibility of the diamond polish pads also means they are suitable for different types of granite. Whether the granite is rough-cut or polished, these pads adjust easily to the stone’s texture, ensuring that the final result is smooth and reflective. Importers can rely on these pads to handle various surface types and deliver consistent results every time.

The growing demand for high-quality granite monuments worldwide makes it more important than ever for importers to find cost-effective, reliable, and high-performance tools. The Diamond Polish Pad made in China delivers all of these features and more, helping to enhance the beauty and longevity of granite monuments while ensuring a quick and efficient process.

If you’re in the business of importing granite monuments, these polish pads are the perfect solution for achieving a flawless, glossy finish every time. Don’t miss out on the opportunity to elevate the craftsmanship of your products with these top-notch tools from China.