Granite Countertop Pads Wholesale Distributor in China

If you’re in the market for high-quality granite countertop pads, sourcing from a reputable distributor in China can be a game changer. With the rising demand for granite countertops in both residential and commercial spaces, the need for reliable accessories, like countertop pads, has also seen a steady increase. These pads not only protect the surfaces of your countertops but also enhance their longevity, ensuring that your investment stays in top shape for years.

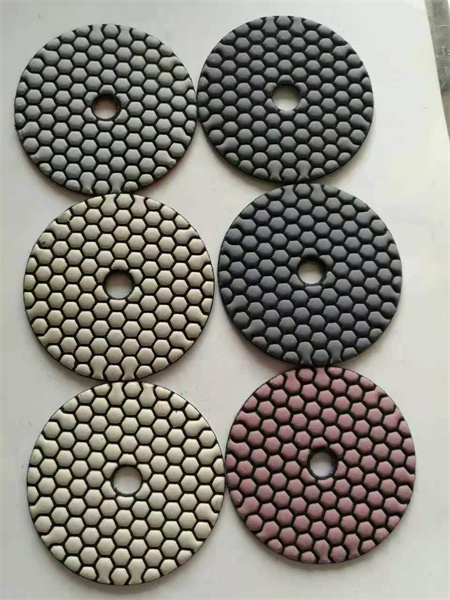

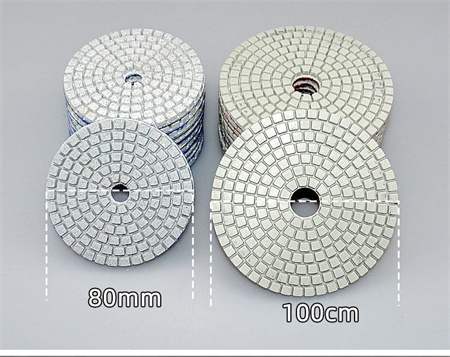

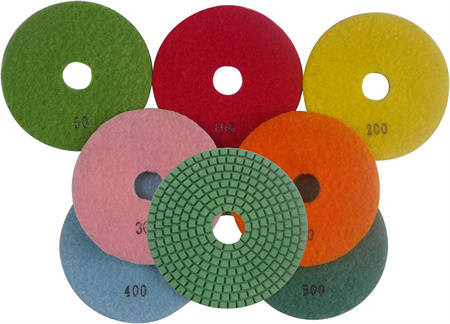

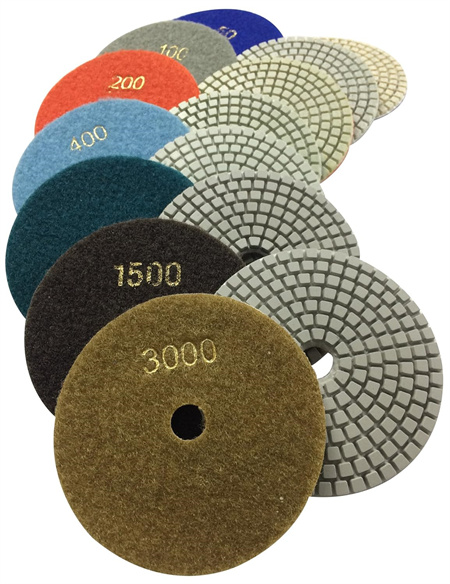

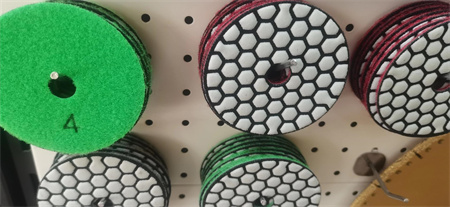

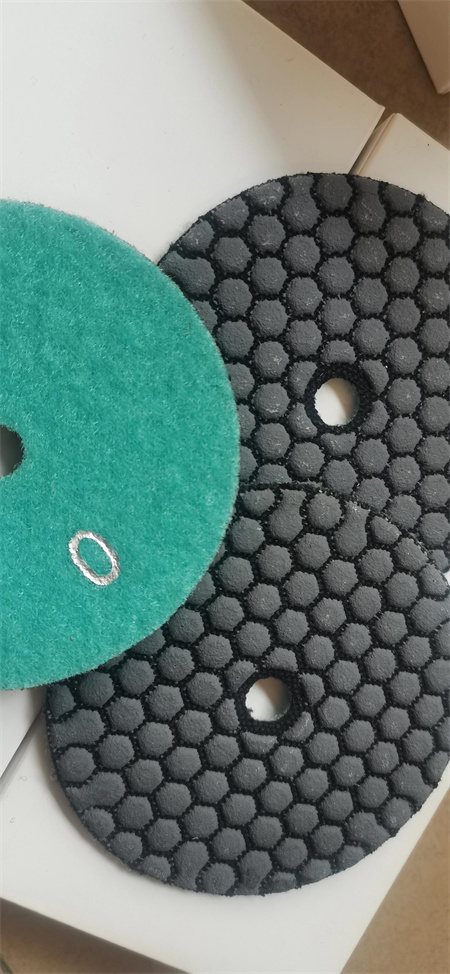

China has long been a hub for manufacturing high-quality materials at competitive prices. This makes it an ideal location for sourcing granite countertop pads in bulk. As a wholesale distributor, China offers a wide variety of pads designed specifically to meet the needs of different types of granite surfaces. Whether you’re working with natural stone countertops or engineered granite, these pads are made to provide optimal protection from scratches, heat, and moisture.

Granite countertops are an investment, and ensuring that they remain in pristine condition is essential for both aesthetic and functional purposes. High-quality countertop pads act as a barrier between hot pots, pans, and utensils, preventing heat damage, which can be a major concern for any kitchen. They also protect against scratches, which can easily mar the surface and diminish the overall beauty of the countertop.

Working with a wholesale distributor based in China offers several advantages. Not only will you benefit from lower costs, but you’ll also have access to a large variety of products that cater to different needs and preferences. The flexibility in customization, such as size and design, ensures that you get products that fit your exact requirements. Whether you’re stocking up for a renovation project or filling orders for clients, buying in bulk allows you to save on costs while getting top-notch quality.

Another advantage of working with Chinese distributors is the efficiency and speed of delivery. With streamlined supply chains and robust logistics networks, distributors can provide fast shipping to various regions across the globe. Whether you’re based in North America, Europe, or elsewhere, your wholesale granite countertop pads can be delivered in a timely manner, ensuring that your business operations run smoothly.

For anyone looking to source granite countertop pads at affordable rates, partnering with a wholesale distributor in China is a smart move. The combination of quality, cost-effectiveness, and reliable shipping makes it a win-win situation. With proper care and the right accessories, your granite countertops will continue to shine for years to come.