Stone Finishing Tools Supplier for Countertop Fabrication and Restoration

When it comes to countertop fabrication and restoration, having the right tools can make all the difference. The intricate work involved in shaping, polishing, and restoring stone surfaces demands precision and expertise. That’s where a reliable stone finishing tools supplier comes in—providing the high-quality tools needed to ensure your countertops are beautifully finished and long-lasting.

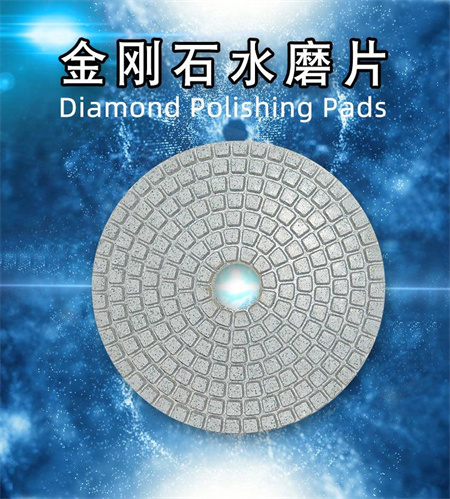

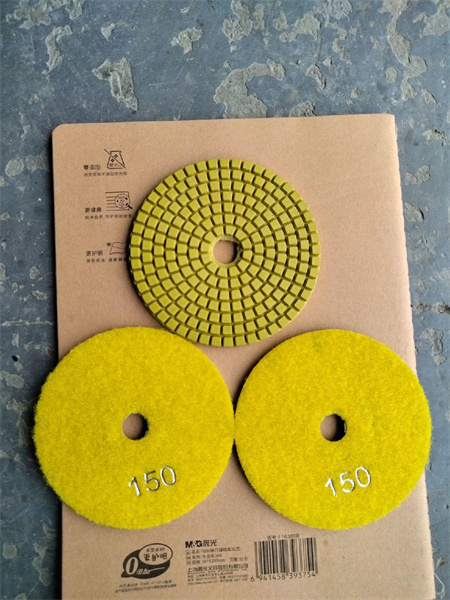

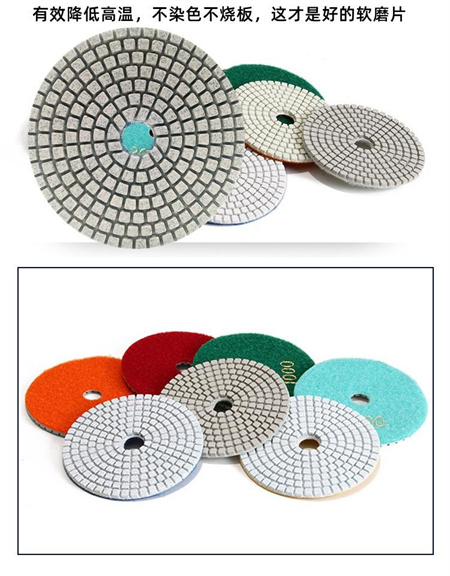

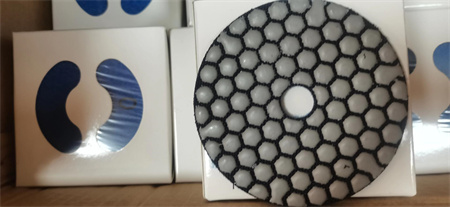

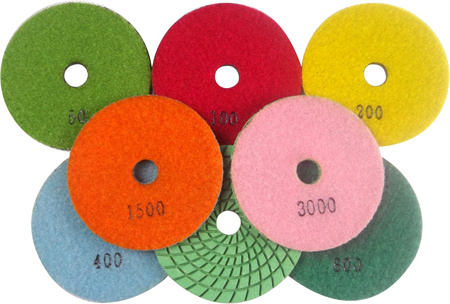

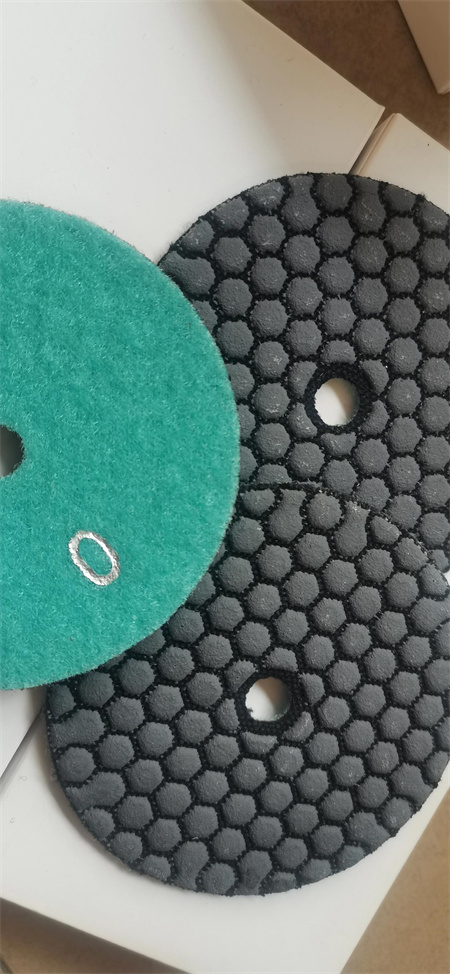

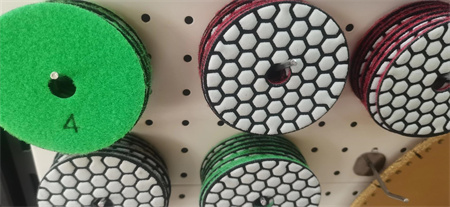

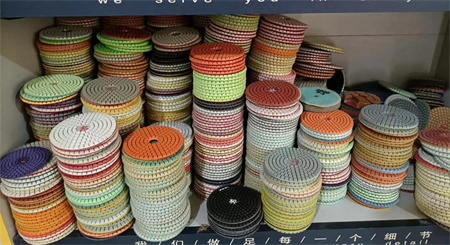

Stone countertops, whether made of granite, marble, or quartz, require specialized tools to achieve that perfect shine and smooth surface. A good supplier understands the unique requirements of different stone types and offers tools designed specifically for each. From diamond pads and polishing machines to edge cutters and grinders, the right selection of tools is essential for creating flawless results.

The fabrication process often involves cutting and shaping large stone slabs to fit specific dimensions. This requires powerful, high-performance tools that can handle the hardness of natural stone without compromising quality. A trusted supplier will provide tools that are durable and built to withstand the demands of stonework, ensuring smooth, precise cuts that fit your exact specifications.

Restoration is another crucial aspect of countertop maintenance. Over time, countertops can lose their luster or become damaged due to wear and tear. Whether it’s removing scratches, restoring a dull surface, or repairing chips, having the right restoration tools is key. A good supplier will offer everything from diamond abrasives to repair kits, making it easy for professionals to restore countertops to their original beauty.

Beyond providing tools, a reputable stone finishing tools supplier also ensures that their products are easy to use, efficient, and compatible with other equipment. Whether you’re a professional fabricator, a contractor, or a DIY enthusiast, having access to top-notch tools can save you time and effort, leading to better outcomes for your countertop projects.

In a competitive industry, where precision and quality are paramount, choosing the right supplier for your stone finishing tools is crucial. The tools you use will not only impact the efficiency of your work but also the overall quality of the final product. By partnering with a trusted supplier, you can ensure that every countertop you work on—whether newly fabricated or restored—meets the highest standards of craftsmanship and durability.

Make sure your next stone project stands out with the right tools and a supplier who understands the importance of quality and reliability.