Diamond Polishing Pads Price Gap Between China and Local Markets

When it comes to diamond polishing pads, a key element for the construction, stone, and flooring industries, pricing differences between China and local markets are significant. Many businesses seeking these products often wonder why the price gap exists and how it impacts their purchasing decisions.

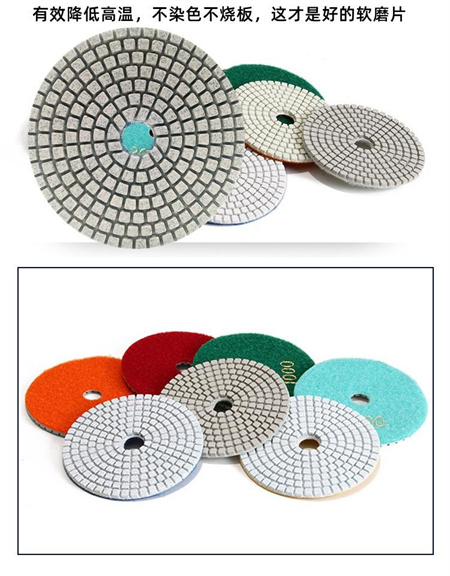

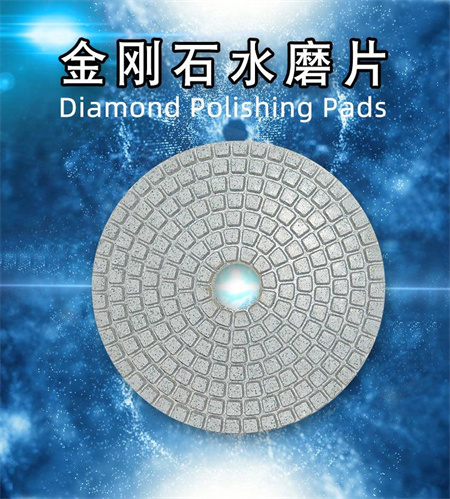

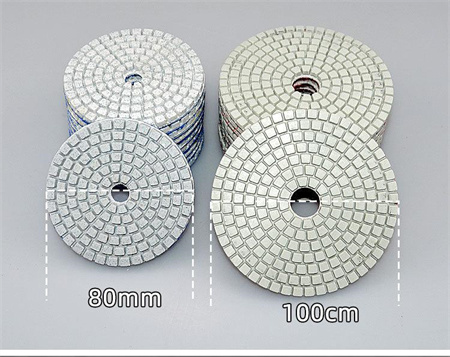

In China, the manufacturing of diamond polishing pads benefits from lower labor costs, mass production capabilities, and economies of scale. These factors combine to keep production costs relatively low. Additionally, China is home to some of the largest producers of diamond tools, which gives local manufacturers a competitive edge in both production volume and price. The availability of raw materials, combined with lower operational costs, further contributes to the affordability of these products. As a result, Chinese suppliers can offer diamond polishing pads at a fraction of the cost compared to their counterparts in local markets.

On the other hand, local markets tend to have higher costs due to factors like labor expenses, manufacturing regulations, and logistical considerations. For instance, shipping and distribution in Western markets can add considerable overhead to the final price of these pads. Import duties and taxes also play a role in making Chinese products more expensive when they reach countries outside of China. Local manufacturers, while producing high-quality goods, face increased production costs, which are passed on to consumers.

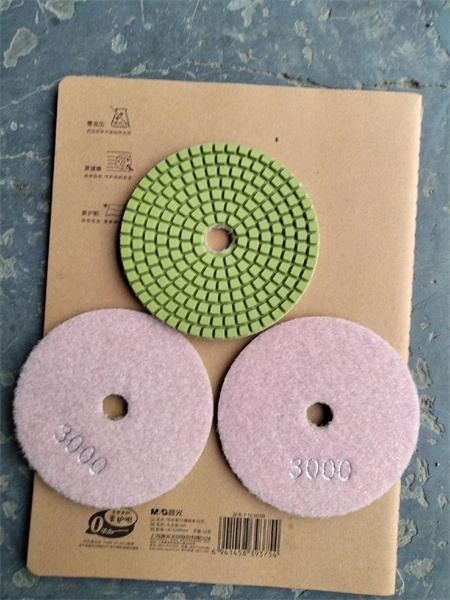

For businesses and consumers, this price gap means that buying diamond polishing pads from China can offer substantial savings. However, the decision is not always about price alone. While Chinese products can offer excellent value, buyers often weigh in other factors such as quality assurance, delivery time, and after-sales support. Some local markets may prioritize these aspects more than price alone, choosing to work with domestic suppliers who can guarantee faster delivery or better customer service.

In short, the price gap between Chinese and local markets is a reflection of various factors such as labor costs, production efficiencies, and international trade regulations. However, businesses should not make their purchasing decisions based solely on price. Quality and service are essential aspects to consider in making the right investment.