Diamond Polishing Disc Manufacturer China Bulk Supply

When it comes to diamond polishing discs, finding a reliable manufacturer for bulk supply is essential for businesses seeking efficiency, quality, and cost-effectiveness. China has emerged as a global leader in the production of high-quality diamond polishing discs, offering competitive pricing and unparalleled manufacturing capabilities. As industries like automotive, construction, and manufacturing continue to rely on diamond discs for surface finishing, it’s clear why sourcing from China is a smart choice for bulk supply.

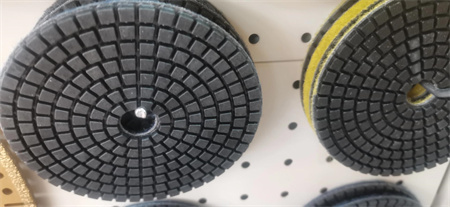

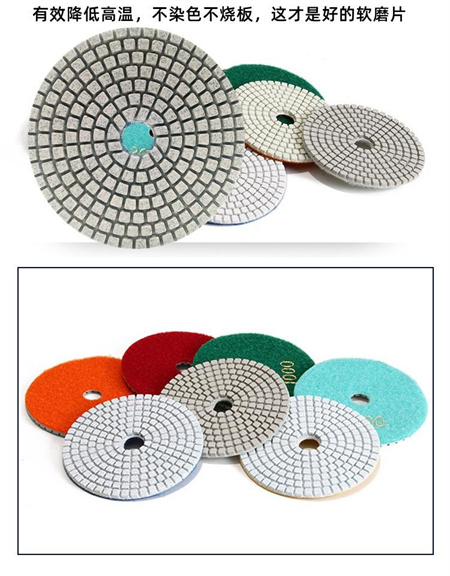

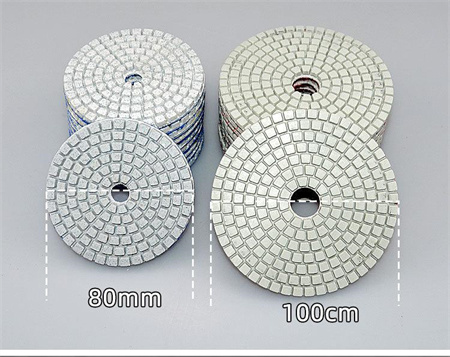

Chinese manufacturers specialize in producing a wide range of diamond polishing discs designed to meet the unique needs of different industries. From industrial-grade polishing tools used in stone processing to precision discs for metalworking, the variety available from Chinese manufacturers is vast. The use of advanced technology and high-quality materials ensures that each disc offers superior performance and durability, whether it’s used for polishing, grinding, or sanding.

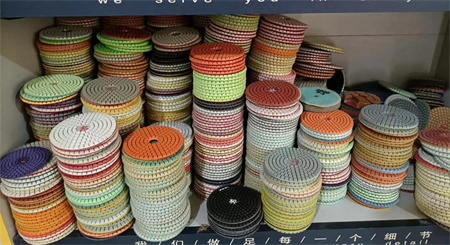

The appeal of buying diamond polishing discs in bulk from China goes beyond just affordability. China’s manufacturing industry has honed its ability to deliver consistent quality, which is crucial for businesses that rely on these tools for large-scale projects. With the capacity to fulfill bulk orders, manufacturers are able to meet tight production schedules, helping businesses maintain a steady supply chain without delays.

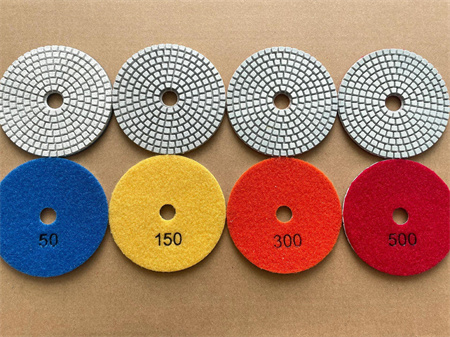

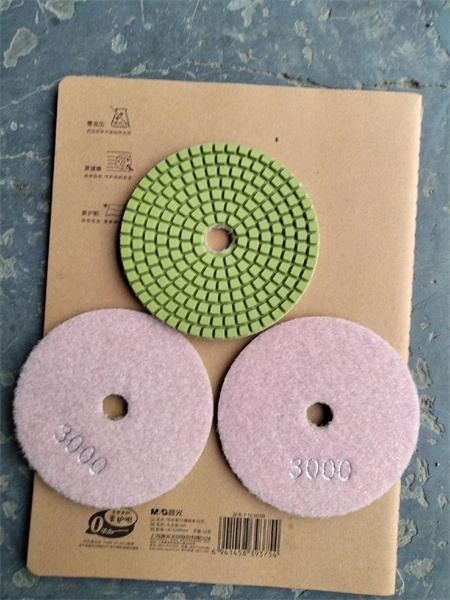

Additionally, many Chinese manufacturers offer customization options to cater to specific needs, whether it’s modifying the grit size or the type of bond for specialized tasks. This flexibility allows companies to source polishing discs that are perfectly suited for their particular requirements. In fact, with the advancements in materials science, some manufacturers even offer eco-friendly options, catering to a growing demand for sustainable products.

Choosing the right manufacturer is key. Businesses looking for a trusted supplier should focus on companies with a solid reputation, excellent customer service, and a proven track record of timely delivery. With China’s vast network of manufacturers and competitive pricing, businesses can achieve both high-quality results and significant cost savings.

In conclusion, if your company requires diamond polishing discs for bulk purchase, China remains a top choice for both affordability and quality. With its extensive manufacturing experience, commitment to innovation, and ability to meet diverse customer needs, Chinese suppliers continue to dominate the global market for diamond polishing products. Whether you’re in construction, automotive, or any other industry, sourcing from a Chinese manufacturer is a smart investment for long-term success.