Granite polishing tool OEM manufacturer for industrial stone importers

When it comes to industrial stone processing, the quality of the tools used can make or break the final product. For stone importers looking for reliable and high-performance granite polishing tools, choosing the right OEM manufacturer is crucial. Whether you’re working with granite countertops, tiles, or intricate stone sculptures, the precision and durability of your polishing tools can elevate your products to the next level.

Granite, known for its toughness and resistance to wear, requires specialized tools to ensure a flawless finish. The process of polishing granite is intricate, demanding not only the right abrasive technology but also consistent performance over time. That’s where an experienced OEM manufacturer comes into play. Partnering with the right company ensures access to cutting-edge technology, high-quality materials, and tools designed for longevity.

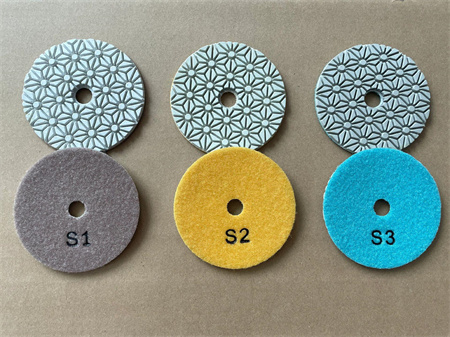

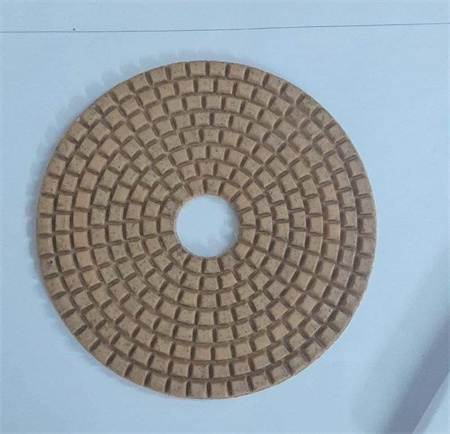

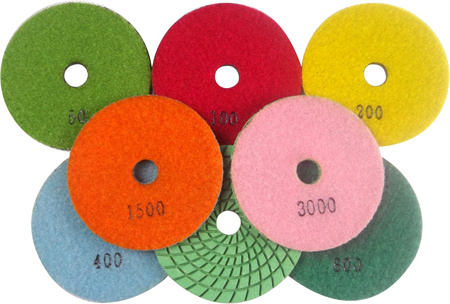

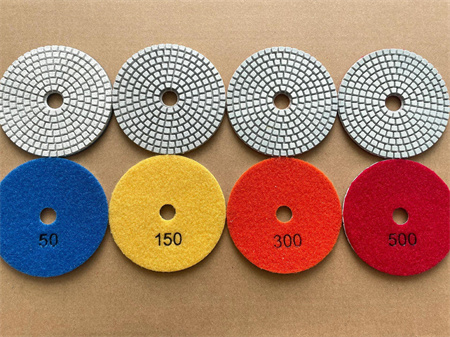

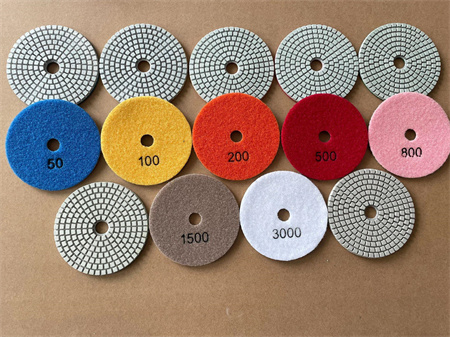

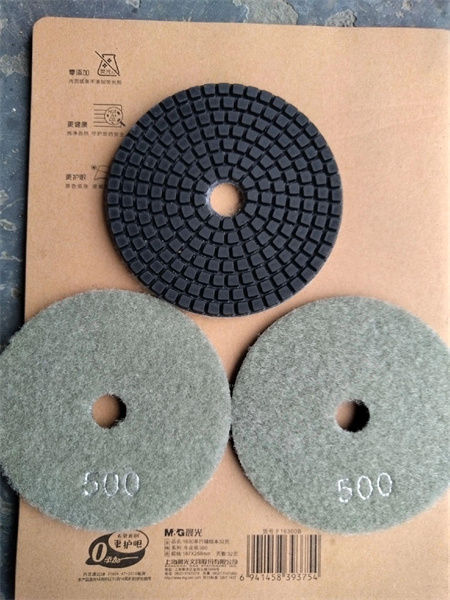

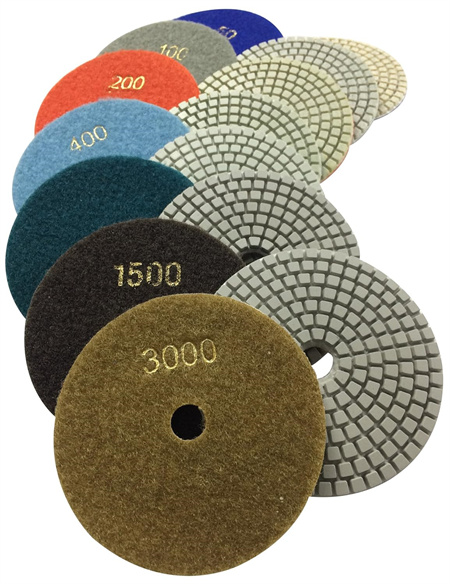

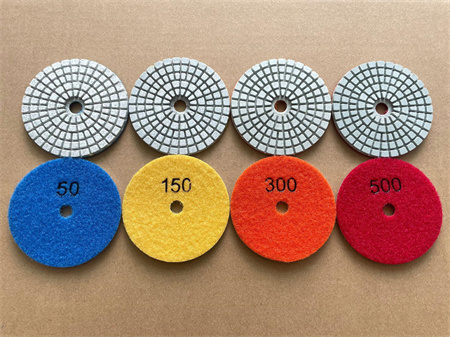

The best OEM manufacturers in the granite polishing industry use state-of-the-art techniques, delivering tools that outperform others in terms of efficiency and finish quality. These manufacturers work closely with stone importers to understand their unique needs, crafting tools that fit the specific requirements of different granite types and processing techniques. From diamond polishing pads to grinding wheels, a wide range of tools is available, each designed for a particular stage in the stone polishing process.

Working with an OEM manufacturer provides stone importers with numerous benefits, including cost efficiency, product customization, and timely delivery. Customization is key, as it allows importers to receive tools tailored to their specific machinery and production methods. Furthermore, a good OEM manufacturer will offer robust after-sales support, ensuring that any issues encountered during the polishing process are swiftly addressed.

In a competitive market where precision and speed are paramount, industrial stone importers cannot afford to compromise on the quality of their tools. Opting for an experienced OEM manufacturer who understands the intricacies of granite polishing can make a world of difference, enabling businesses to offer superior stone products that stand out in a crowded marketplace.

Whether you’re just starting in the stone industry or looking to upgrade your existing operations, selecting the right granite polishing tool manufacturer is a key decision. The right partner can enhance your workflow, improve product quality, and ultimately, boost your bottom line.