Professional Diamond Polishing Pads Bulk Exporter

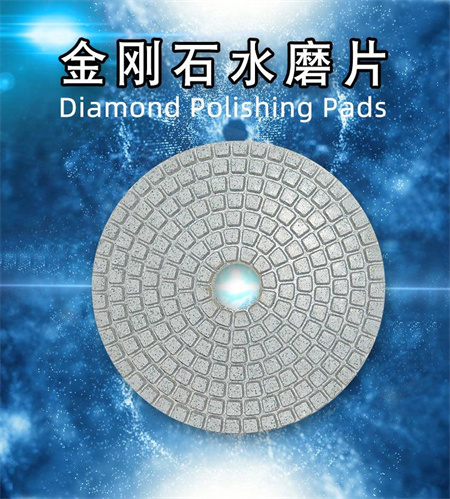

When it comes to achieving that perfect, glossy finish on various surfaces, diamond polishing pads are a must-have. These high-performance tools are used across industries, from stone and marble to concrete and granite, ensuring that surfaces are polished to perfection. As a professional diamond polishing pads bulk exporter, we understand the importance of quality, reliability, and consistency in every product we supply.

Our diamond polishing pads are crafted with precision, using top-quality materials to deliver exceptional results. Whether you’re working on large-scale commercial projects or smaller-scale DIY tasks, our products are designed to cater to all types of polishing needs. With their superior durability and long-lasting performance, these pads ensure that every project finishes with the smoothest, most refined surface.

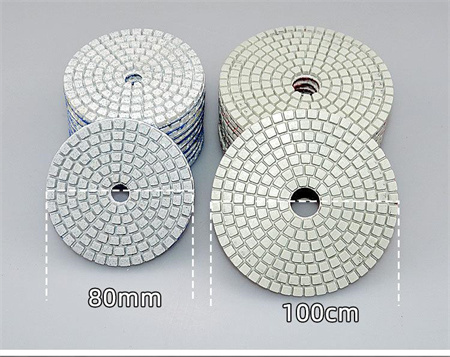

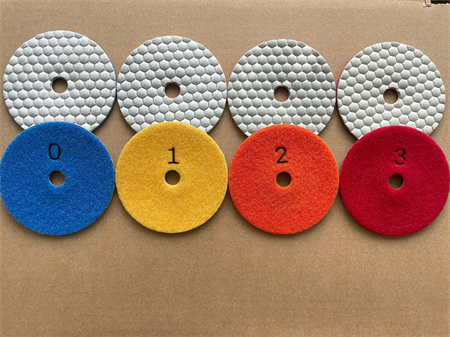

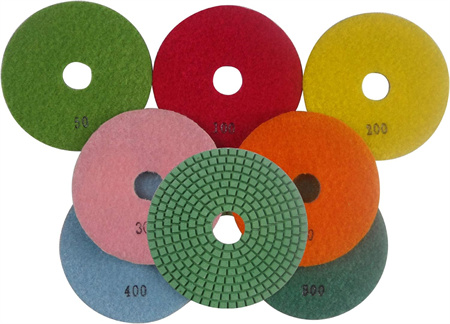

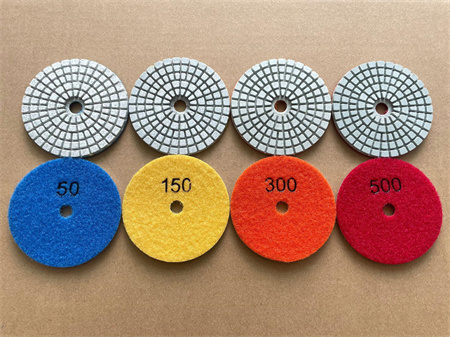

One of the key benefits of choosing our diamond polishing pads is their versatility. They are available in various grits, from coarse to fine, allowing you to tackle different stages of the polishing process with ease. Each pad is designed to be highly effective, providing fast material removal and minimizing wear and tear on your equipment. This makes them a cost-effective solution, especially when purchased in bulk for large-scale operations.

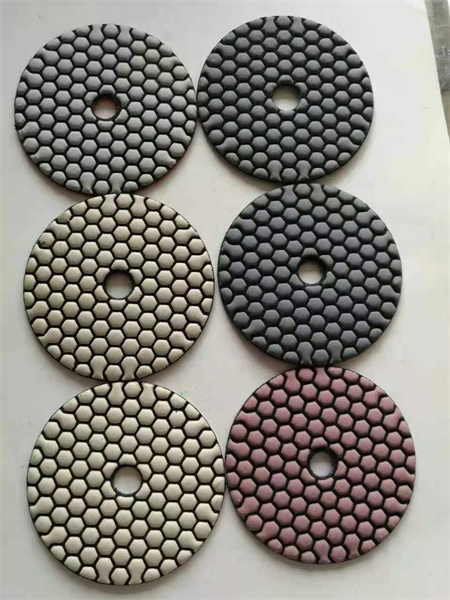

What sets us apart as a trusted bulk exporter is our commitment to delivering products that meet international standards. We work closely with leading manufacturers to ensure that each batch of diamond polishing pads meets the highest levels of quality and performance. We take pride in offering a range of pads suitable for both dry and wet polishing, providing our clients with the flexibility to choose based on their specific requirements.

For businesses in the construction, stone fabrication, and flooring industries, having access to reliable and durable polishing pads is crucial for maintaining high productivity and delivering excellent results. Our bulk export services make it easier for companies to access top-quality diamond polishing pads without the hassle of sourcing from multiple suppliers. We ensure timely delivery, competitive pricing, and the best customer service in the industry.

If you’re looking for a trusted source of professional-grade diamond polishing pads, we are here to help. We offer an extensive selection of pads in bulk, tailored to meet the needs of your projects. Reach out to us today and discover how we can elevate your polishing process with our high-performance pads.