Marble Polishing Disc Wholesale for Countertop Restoration Companies

When it comes to restoring the timeless beauty of marble countertops, the right tools can make all the difference. Countertop restoration companies understand the importance of quality products that help them achieve flawless finishes. Marble polishing discs are an essential tool in this process, and when purchased in bulk, they offer both efficiency and cost-effectiveness for businesses in the industry.

Marble, with its elegant appearance and classic charm, can accumulate scratches, stains, and wear over time. Whether it’s a kitchen countertop, bathroom vanity, or a decorative marble surface, restoration is often the only way to bring it back to its pristine condition. This is where a reliable marble polishing disc comes into play, offering the power to remove imperfections, restore the natural shine, and extend the life of the stone.

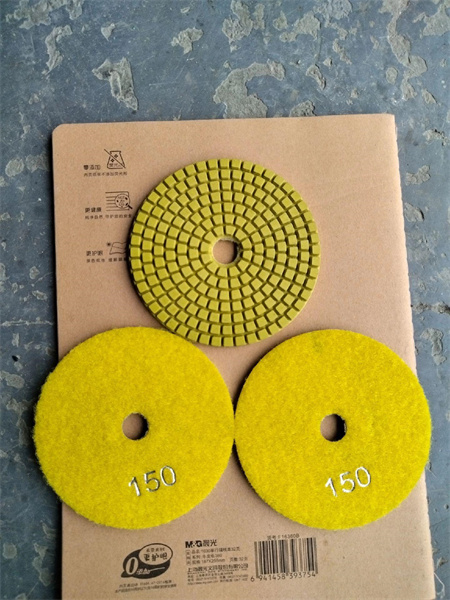

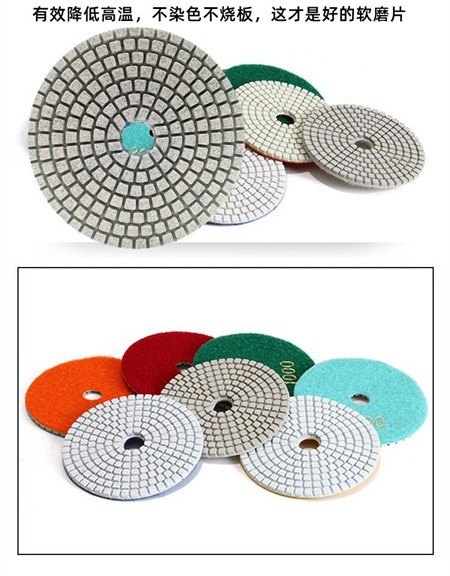

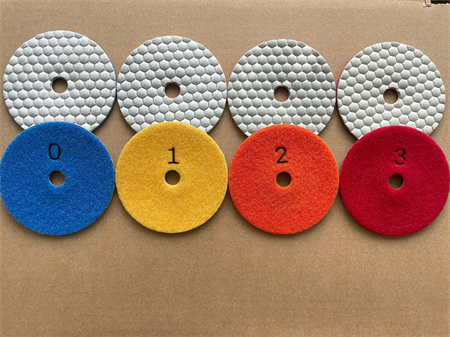

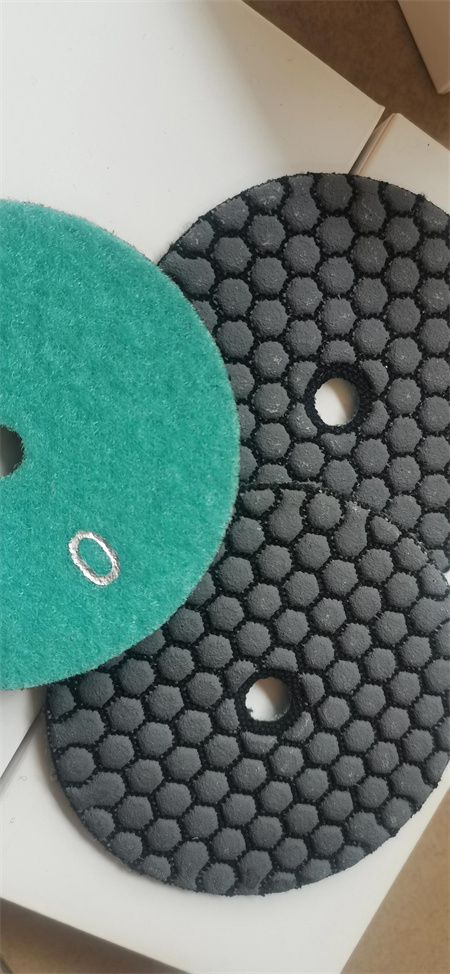

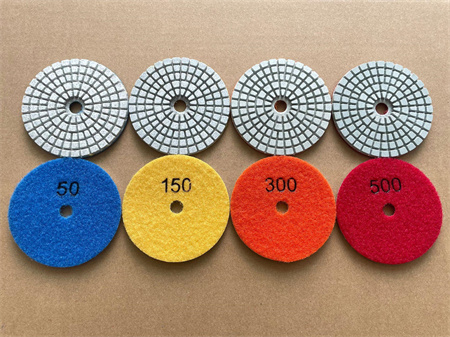

The secret to achieving a high-quality finish lies in the selection of the right polishing discs. Wholesale purchasing ensures that countertop restoration companies have a steady supply of high-performance discs for all their restoration needs. With the right equipment, technicians can work more efficiently, saving time while delivering stunning results. Polishing discs vary in grit size, which affects their ability to smooth, buff, or shine marble surfaces. For instance, discs with a higher grit number are perfect for final polishing, while lower-grit options work wonders on deeper scratches and imperfections.

Bulk orders of marble polishing discs not only reduce the per-unit cost but also provide a convenience factor. With larger quantities on hand, restoration businesses can handle multiple projects simultaneously, avoiding delays that may arise from having to reorder supplies mid-job. Additionally, having a steady stock of these essential tools helps companies plan ahead and manage their resources more effectively.

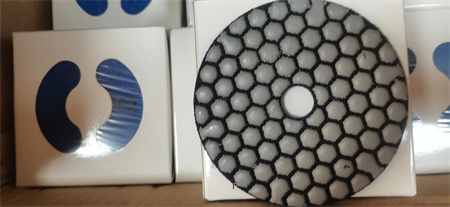

For countertop restoration companies, choosing high-quality polishing discs is crucial to maintaining a reputation for excellence. Discs made from durable materials ensure that the restoration process is smooth and efficient, leaving behind a marble surface that looks as good as new. It’s also important to consider the compatibility of these discs with various polishing machines, ensuring they provide maximum performance without causing damage to the surface being worked on.

In the competitive world of countertop restoration, having access to top-notch tools can set a business apart from its competitors. Marble polishing discs bought wholesale allow restoration companies to offer their clients outstanding results, boosting satisfaction and encouraging repeat business. When the right tools are paired with skilled technicians, the results speak for themselves—transforming worn-out marble countertops into sparkling, like-new surfaces that are sure to impress.

For countertop restoration companies looking to streamline their operations and improve the quality of their services, investing in marble polishing discs wholesale is a step in the right direction.