Stone finishing tools OEM manufacturer for countertop fabrication importers

When it comes to countertop fabrication, the quality of the stone finishing tools is crucial. Importers of countertop materials know that sourcing high-quality equipment is essential to ensure precision, efficiency, and durability in their work. As an OEM manufacturer of stone finishing tools, we provide reliable solutions that meet the demanding needs of countertop fabricators worldwide.

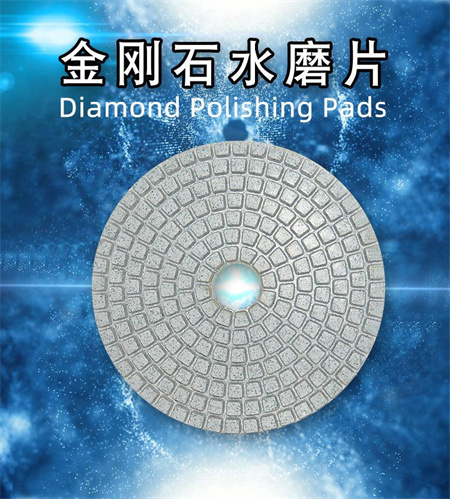

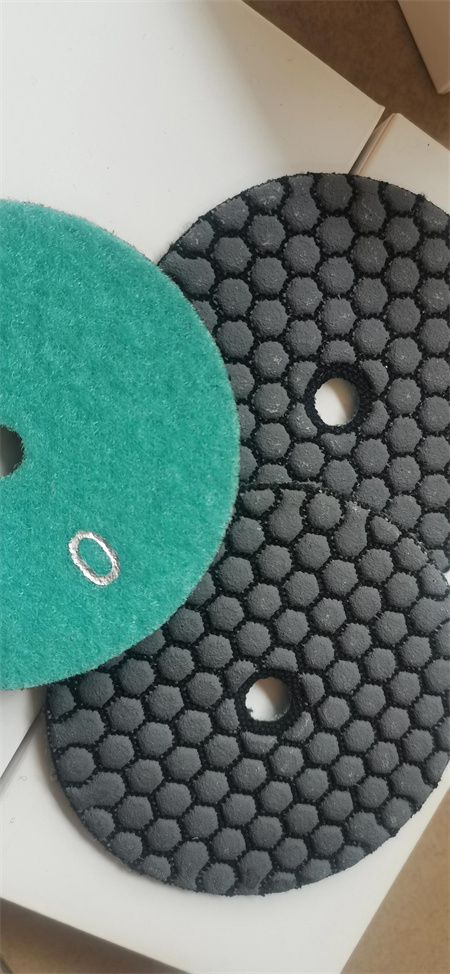

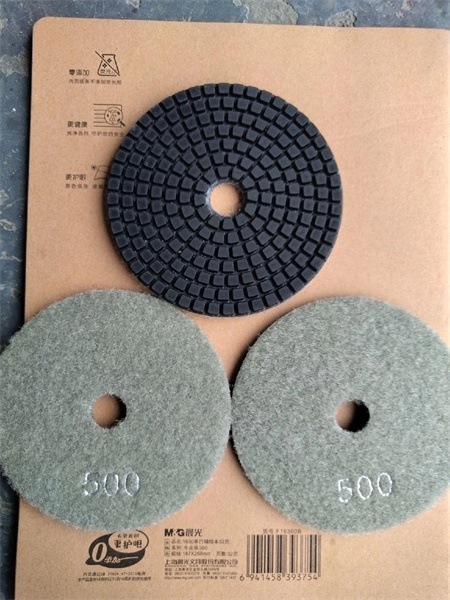

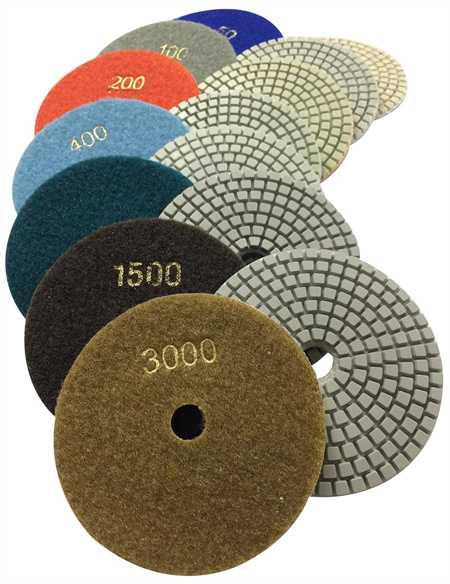

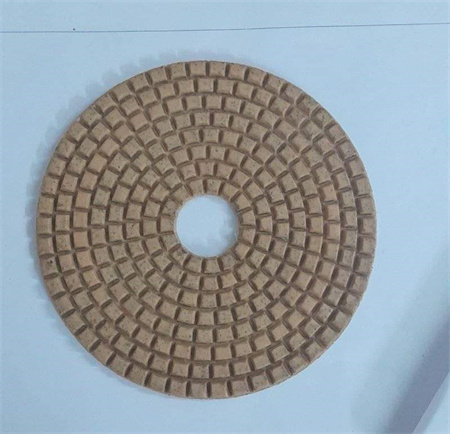

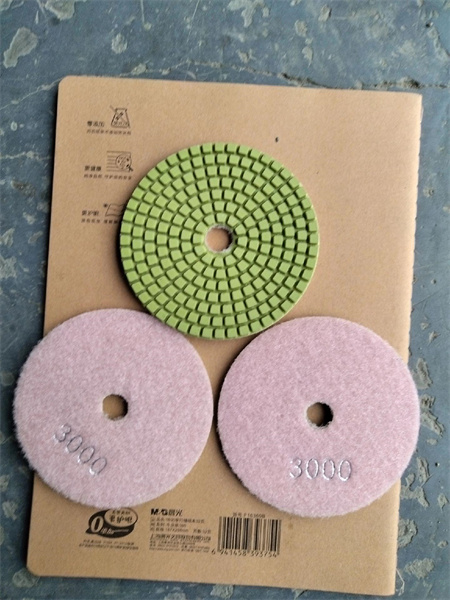

Our stone finishing tools are designed to handle a wide variety of tasks, from smoothing rough edges to achieving a glossy, polished surface. Whether you’re working with granite, marble, quartz, or other natural stone materials, our tools deliver consistent, high-end results every time. By using cutting-edge technology and superior materials, we create tools that are not only durable but also versatile, helping fabricators achieve their desired finishes more efficiently.

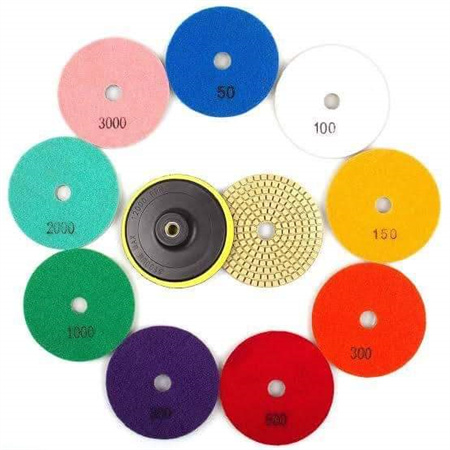

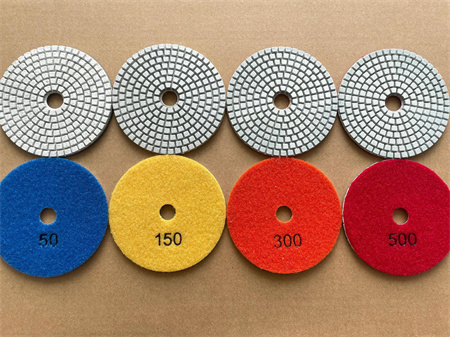

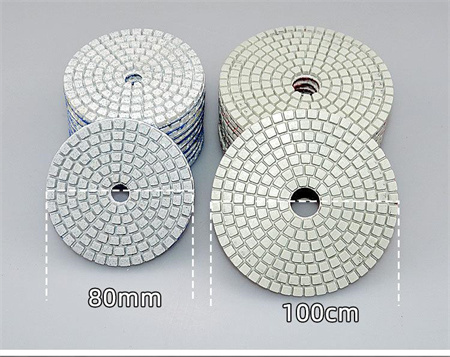

We understand the pressures of meeting tight deadlines and managing high volumes of countertop production. That’s why we’ve developed a range of tools that can be relied upon in even the most fast-paced environments. From polishing pads to grinding wheels and cutting blades, our products are engineered for ease of use and long-lasting performance, allowing fabricators to maintain productivity without sacrificing quality.

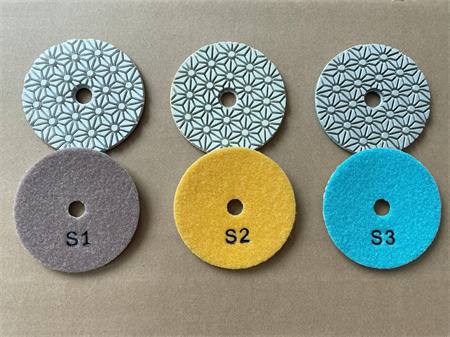

Our OEM manufacturing capabilities also allow us to tailor stone finishing tools to the specific needs of countertop fabricators. Whether you require a particular size, shape, or feature for your tools, we can create custom solutions that perfectly align with your workflow. With our robust production process and attention to detail, you can trust that every tool we supply will meet your exact specifications.

For countertop fabricators, sourcing tools from a trusted OEM manufacturer can make all the difference. By choosing us as your partner, you gain access to the latest advancements in stone finishing technology, ensuring that your production processes remain competitive and efficient. Our commitment to excellence and customer satisfaction makes us the ideal choice for importers who are looking to offer their clients the best stone finishing tools available.

Get in touch today to learn more about our stone finishing tools and how we can support your countertop fabrication business with high-quality, custom solutions.