Tips for Bulk Ordering Diamond Polishing Pads

When it comes to maintaining the shine and luster of surfaces, diamond polishing pads are indispensable. These high-performance tools are used in various industries, from stone and concrete polishing to glass and ceramics. If you’re in the market for bulk ordering diamond polishing pads, whether you’re a wholesaler, importer, or retail store, there are several key factors you should consider to ensure you make an informed and cost-effective purchase. Here’s a comprehensive guide to help you navigate the process.

1. Understand the Types of Diamond Polishing Pads

Before placing a bulk order, it’s crucial to understand the different types of diamond polishing pads available. They vary based on their intended application and the surface they are meant to polish. Here are the primary types:

– Wet Polishing Pads: Ideal for granite, marble, and other natural stones. These pads are used with water to keep the surface cool and reduce dust.

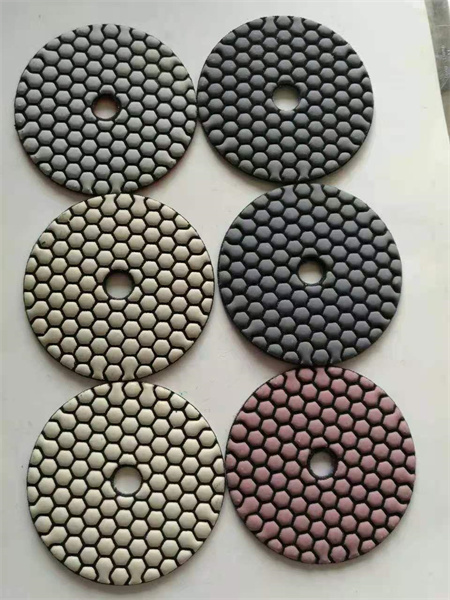

– Dry Polishing Pads: Best for concrete and stone surfaces where water might not be practical. They are designed to work without water, making them suitable for indoor environments.

– Resin-Bonded Pads: These pads are known for their durability and are used for polishing harder materials like granite and concrete.

– Metal-Bonded Pads: Generally used for initial grinding and coarse polishing. They are designed to remove material quickly and are suitable for rougher surfaces.

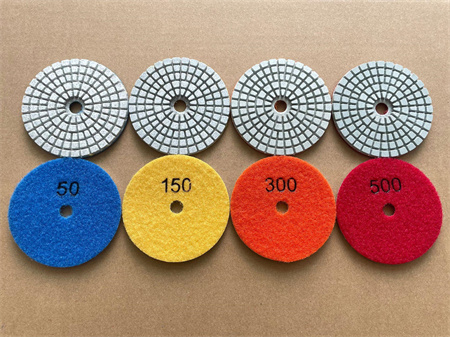

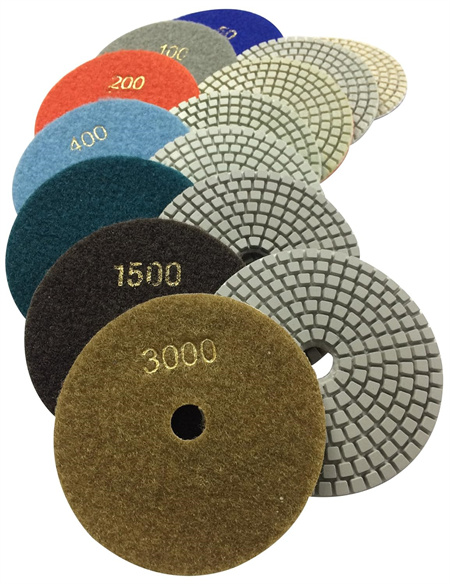

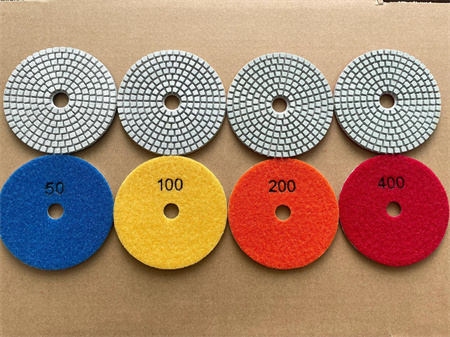

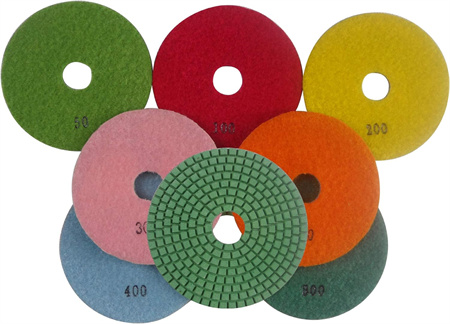

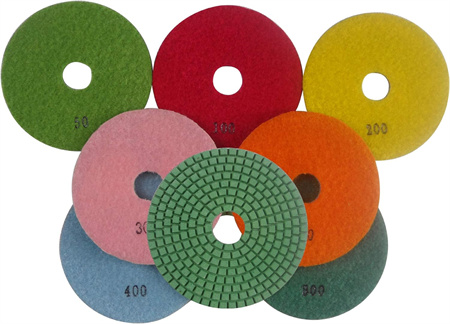

2. Determine the Grit Sizes You Need

Diamond polishing pads come in various grit sizes, ranging from coarse to fine. The grit size affects the level of smoothness and shine. For bulk ordering, consider the range of grit sizes you will need:

– Coarse Grit (50-200): For initial grinding and heavy material removal.

– Medium Grit (400-800): For smoothing the surface and preparing it for finer polishing.

– Fine Grit (1500-3000): For achieving a high gloss and final finish.

It’s important to order a balanced mix of grit sizes based on your specific polishing needs.

3. Choose the Right Backing and Attachment Types

Diamond polishing pads come with various backing types and attachment methods:

– Hook and Loop (Velcro): Allows for quick and easy pad changes. Commonly used in conjunction with polishing machines.

– Self-Adhesive: These pads stick directly to the polishing machine without the need for additional attachments.

– Clip-On: Suitable for machines that use a clip-on mechanism.

Choose the type that best suits your polishing equipment and workflow.

4. Assess Quality and Durability

Quality and durability are crucial factors, especially when ordering in bulk. High-quality pads will have a longer lifespan and better performance. Look for pads made with high-grade diamond abrasives and robust bonding materials. Conducting a few sample tests before placing a large order can help you gauge the quality.

5. Consider the Manufacturer’s Reputation

Selecting a reputable manufacturer ensures that you receive reliable products and support. Research manufacturers with a track record of producing high-quality diamond polishing pads. Read customer reviews and ask for references if necessary. Since you’re working with a Chinese manufacturer, consider their experience in exporting and their ability to meet international standards.

6. Evaluate Pricing and Bulk Discounts

Bulk ordering often comes with the advantage of reduced pricing. Compare quotes from different suppliers and evaluate the cost per unit. Be sure to consider shipping costs and any potential import duties. Some suppliers may offer additional discounts for large orders, so don’t hesitate to negotiate.

7. Ensure Compliance with Industry Standards

Depending on your location and industry, certain standards and regulations may apply to diamond polishing pads. Ensure that the products you order comply with relevant standards for safety and performance. This is particularly important if you are reselling the pads or using them in commercial applications.

8. Plan for Shipping and Logistics

Shipping logistics can impact the overall cost and delivery time of your order. Coordinate with your supplier to understand shipping options, lead times, and delivery schedules. Make sure that the pads are packaged securely to prevent damage during transit.

9. Understand After-Sales Support

After-sales support is an important aspect of bulk purchasing. Ensure that the manufacturer offers support in case of any issues with the pads. This includes warranty coverage, return policies, and customer service. A reliable support system can save you from potential headaches down the line.

10. Stay Updated with Industry Trends

The diamond polishing pad industry is continually evolving with new technologies and innovations. Stay informed about the latest trends and advancements to ensure you are offering the best products to your customers. This can also help you make better decisions for future bulk orders.

In summary, bulk ordering diamond polishing pads involves careful consideration of product types, grit sizes, quality, manufacturer reputation, pricing, compliance, and logistics. By following these tips, you can ensure that your bulk purchase is both cost-effective and meets the needs of your business or customers.