Setting Up a Polishing Station at Home or Workshop

Whether you’re a seasoned DIY enthusiast or just starting to dabble in the world of home improvement, a well-organized polishing station can make all the difference. Whether you’re polishing metal, wood, plastic, or even stones, having a dedicated space can streamline the process, improve results, and make your work more enjoyable. The key is setting up a space that suits your specific needs, giving you the tools and environment to achieve professional-quality finishes.

Creating your polishing station doesn’t need to be a complicated or expensive process. With a few essential components and a little creativity, you can transform any corner of your home or workshop into a space that encourages efficiency and precision. Here’s how you can get started.

Choose the Right Location

The first step in creating your polishing station is finding the perfect location. Ideally, your space should be well-ventilated, free from dust, and spacious enough for your tools, materials, and workspace. A workbench is often a great starting point—something sturdy that can handle the vibrations of a polishing tool without wobbling. If you don’t have a designated workbench, any stable surface will do. Just ensure that it’s large enough to accommodate your items and leave some room for maneuvering.

Select the Right Tools

When setting up your polishing station, the most important investment will be in the tools you’ll be using. The type of polishers you choose will depend on what materials you plan to work with. For example, a rotary tool with polishing attachments works wonders for metal, while an orbital sander with buffing pads is ideal for smooth wooden surfaces.

Here’s a basic list of essential tools:

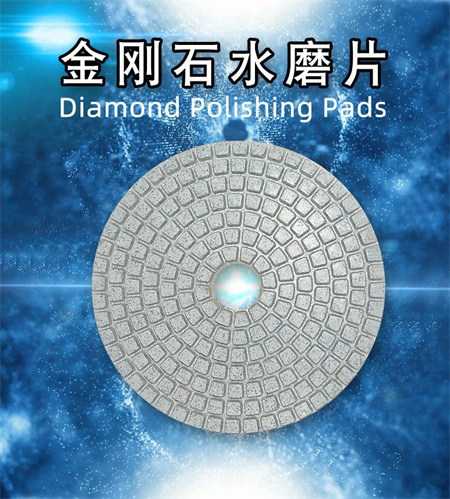

1. Polisher: Choose a high-quality polisher based on the material you’re working with. For metals, a rotary polisher may be best, while a random orbital polisher is gentler and more versatile for various surfaces.

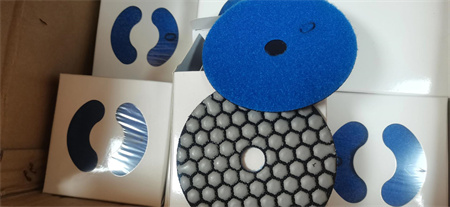

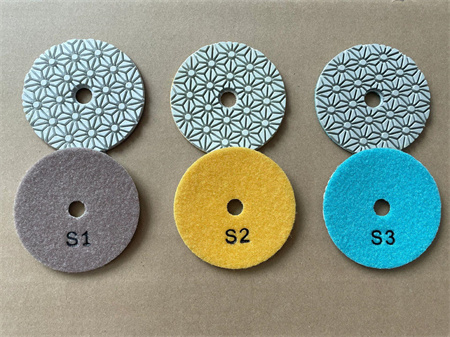

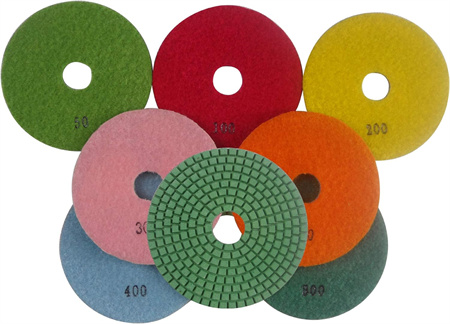

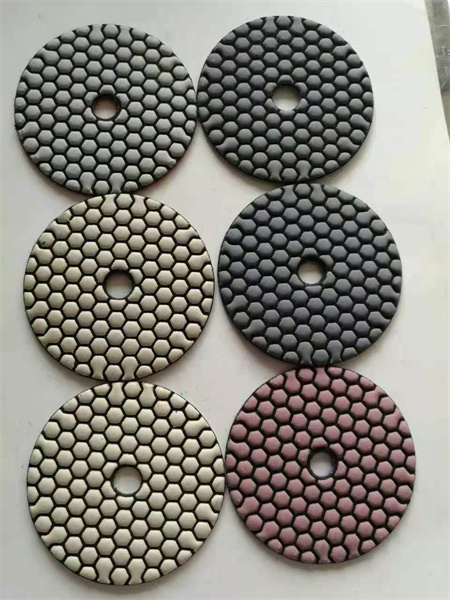

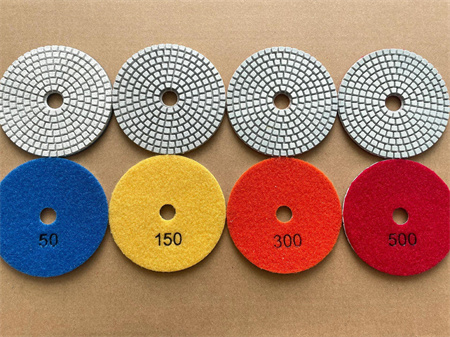

2. Buffing Pads and Brushes: Stock up on a variety of buffing pads and brushes. Different grits of pads will help you work through different stages of polishing, from coarse to fine finishes.

3. Polishing Compounds: Depending on your project, you’ll need polishing compounds that match the material you’re working on. For example, metal polishing compounds, waxes for wood, and specific compounds for plastics or stones.

4. Safety Gear: Never compromise on safety. Always have eye protection, dust masks, and ear protection, especially if you’re working with power tools that generate dust and noise.

Organize Your Workspace

Once you have your tools, it’s time to get organized. Storage bins, shelves, and pegboards can keep your tools and compounds easily accessible. You want everything within arm’s reach but also clearly labeled or grouped by use. For example, place all your metal-polishing compounds together, separate from your wood-specific materials.

A rolling cart or tool caddy can be a great addition if you need to move your supplies around. Keeping your station tidy will not only help you find tools more easily but also minimize distractions during long polishing sessions.

Safety Precautions

Safety is paramount when setting up your polishing station. The polishing process can generate a significant amount of dust, which may be harmful to your lungs if inhaled over time. Wearing a dust mask is crucial, and you may even want to invest in a dust collection system or a simple shop vac with a dust bag to help keep your workspace cleaner and safer.

Along with a dust mask, wear safety glasses to protect your eyes from flying debris, especially when working with metal or harder materials. Earplugs or earmuffs are also essential, as the noise from power polishers and sanders can be quite loud.

Before you dive into any major projects, it’s always a good idea to test your setup. Start by polishing a small, inexpensive object to get a feel for the process. This will help you determine if everything is functioning as it should and whether your workspace is comfortable. Adjust the positioning of tools, lighting, and storage based on how you work best.

Maintenance and Care

A polishing station is an investment in your craft, and just like any other tool, it needs regular care and maintenance. Make sure to clean your tools after every use to extend their lifespan and maintain optimal performance. Buffing pads can get clogged with compounds, so it’s important to clean them or replace them as necessary.

You’ll also want to periodically check the condition of your workbench or station, making sure that it remains sturdy and functional. If you notice any issues with your polisher or other equipment, address them promptly to avoid potential accidents.

Conclusion