China Diamond Polishing Pad Distributor Bulk Orders

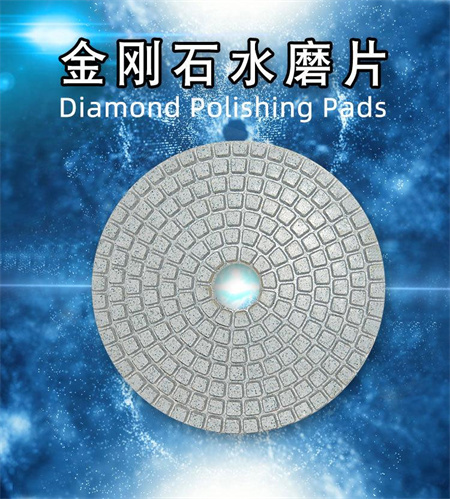

When it comes to sourcing high-quality diamond polishing pads, China stands out as a global leader, offering excellent products at competitive prices. Whether you’re in the stone, concrete, or flooring industry, finding the right distributor for bulk orders can make a significant difference in the efficiency and cost-effectiveness of your operations.

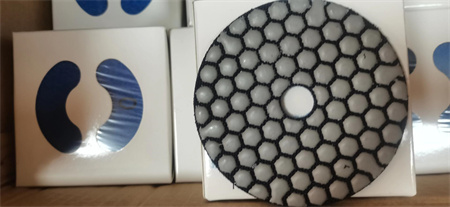

One of the biggest advantages of purchasing diamond polishing pads in bulk from China is the ability to access top-tier products that meet international standards. Chinese manufacturers are known for their cutting-edge technology, robust production capabilities, and commitment to quality. This ensures that businesses get durable and reliable pads, capable of delivering superior polishing results on a variety of surfaces.

For distributors, ordering in bulk allows for cost savings that can be passed on to customers. Bulk purchasing also offers a reliable supply chain, ensuring that companies can meet their production needs without worrying about stockouts. This is particularly important in industries where consistency and timing are crucial, such as in construction and flooring installation.

Working with a reputable Chinese distributor offers several key benefits beyond just pricing. Many of these suppliers have years of experience in international trade and understand the complexities of shipping and customs processes. As a result, businesses can expect smooth transactions and timely deliveries, even when placing large orders.

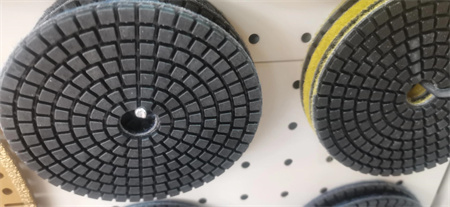

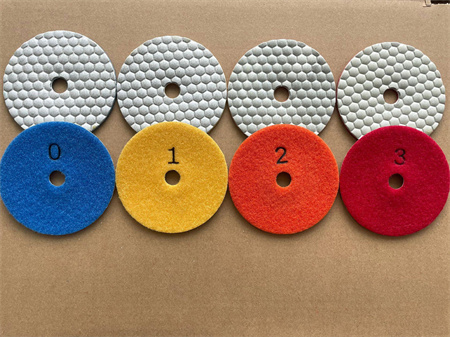

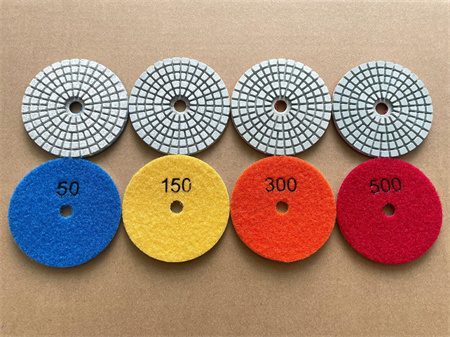

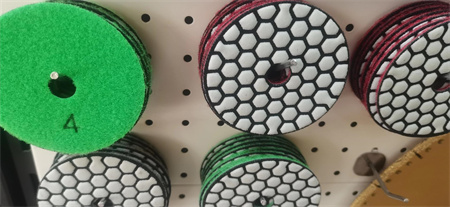

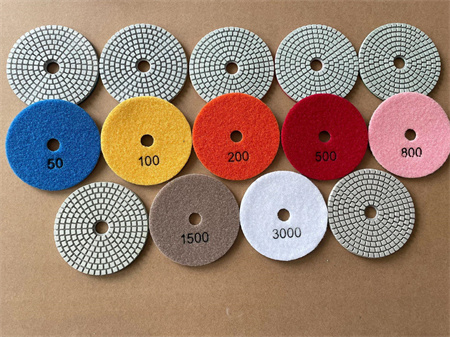

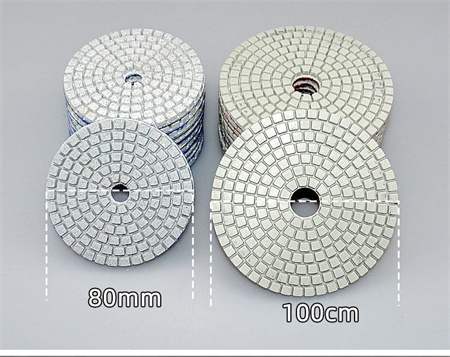

Another notable advantage is the customization options available. Many Chinese distributors offer flexibility in product specifications, allowing customers to request diamond polishing pads tailored to their specific needs. Whether you require a specific grit size, thickness, or shape, these suppliers can accommodate your requirements, ensuring that you receive the ideal products for your polishing tasks.

Moreover, as the demand for eco-friendly and efficient products rises, Chinese manufacturers are increasingly focusing on sustainable production methods. This shift allows businesses to align with environmentally conscious practices while still enjoying the high performance that diamond polishing pads are known for.

In conclusion, ordering bulk diamond polishing pads from a trusted Chinese distributor presents a cost-effective solution for businesses looking to maintain high product quality and performance. With numerous benefits ranging from competitive pricing to customization options and dependable shipping, it’s no surprise that China remains a top choice for those in need of high-quality polishing solutions.