Diamond Polishing Pads E-commerce Wholesale Supply from China

When it comes to achieving flawless finishes in stone, marble, or concrete surfaces, diamond polishing pads stand as the go-to solution. As the demand for high-quality tools increases globally, e-commerce wholesale suppliers in China have emerged as a leading source for businesses looking to stock up on these essential products. With their competitive prices, wide selection, and consistent supply, Chinese suppliers are making it easier than ever to access top-tier diamond polishing pads for various industries.

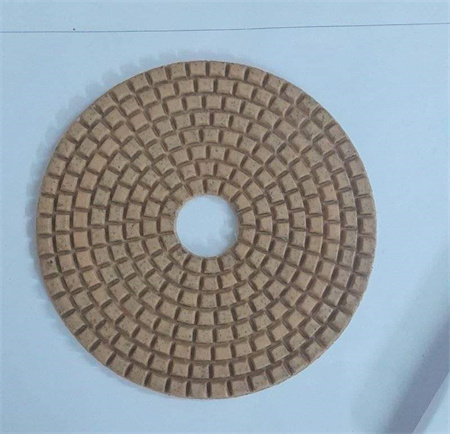

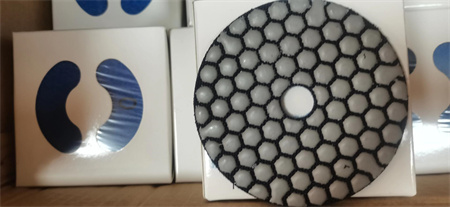

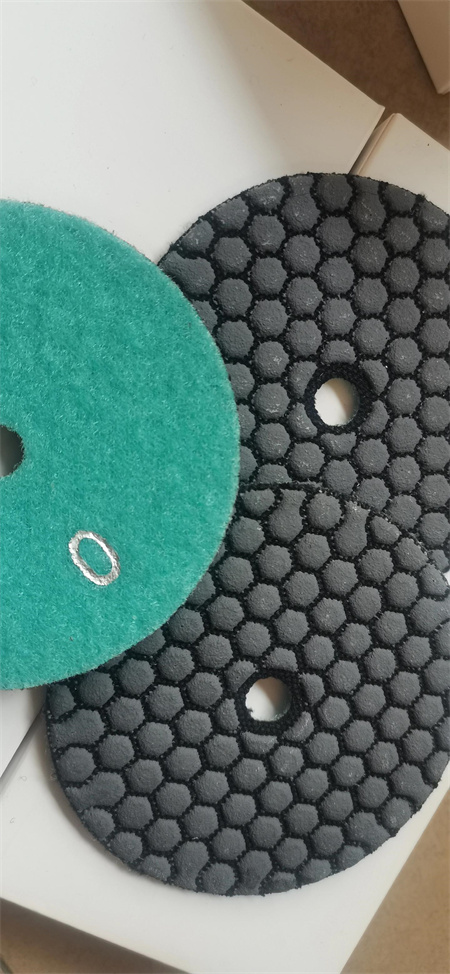

China’s dominance in the manufacturing sector has led to the development of high-performance diamond polishing pads that can cater to both professional and personal needs. These pads are designed to give surfaces that perfect shine, without the hassles of frequent replacements. Whether for use on granite countertops, concrete floors, or marble walls, the ability to find the right pad at affordable prices is crucial for businesses looking to stay ahead in a competitive market.

E-commerce platforms in China have streamlined the process of purchasing diamond polishing pads in bulk, offering everything from entry-level pads to premium varieties for heavy-duty polishing. Not only do these platforms provide convenient online ordering systems, but they also offer excellent customer service to ensure that the right product reaches the customer every time. From the moment an order is placed to when it arrives at your doorstep, you can expect a seamless transaction.

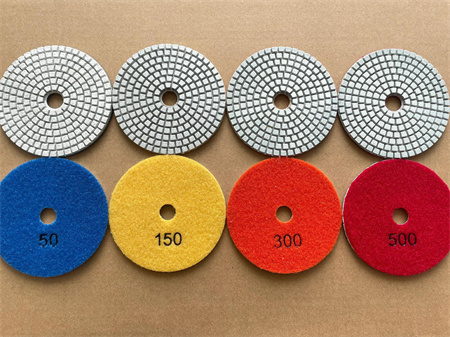

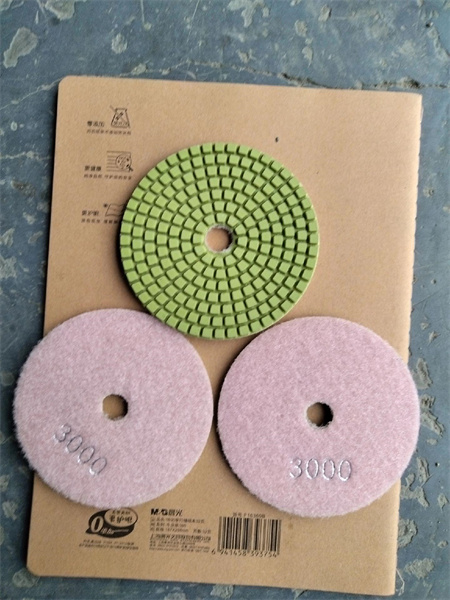

China’s wholesale e-commerce industry stands out for its ability to provide a diverse range of diamond polishing pads suited to different needs. Whether you’re a small business or a large enterprise, finding a reliable source for these products can make a significant difference in product quality and overall efficiency. The extensive catalog of options allows businesses to choose based on the specific material, grit size, and intended use, ensuring maximum performance and durability.

What sets these products apart is the continuous innovation in diamond polishing pad technology. Manufacturers in China are constantly refining their processes, ensuring that each pad not only performs well but also lasts longer. This ongoing development leads to pads that offer superior polishing results while maintaining cost-effectiveness, a combination that is highly sought after in the global marketplace.

For businesses looking to purchase diamond polishing pads, the benefits of sourcing them from China’s e-commerce wholesale platforms are clear. Affordable pricing, product variety, and reliability are just a few reasons why this market is booming. By connecting directly with trusted suppliers, you can secure high-quality products that will give your customers the results they’re looking for, every time.

In conclusion, sourcing diamond polishing pads from China through e-commerce wholesale supply channels is a smart business move. With high-quality products at competitive prices and a convenient purchasing process, it’s easier than ever to find the perfect solution for your polishing needs.