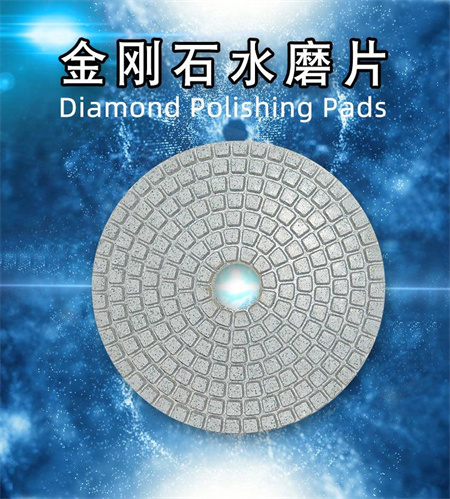

Cheap Diamond Polishing Pads Direct from Manufacturer

Looking for high-quality diamond polishing pads at unbeatable prices? You’re in the right place. Whether you’re a professional in the stone industry or a DIY enthusiast working on home projects, buying directly from the manufacturer is your best bet for saving money without compromising on quality.

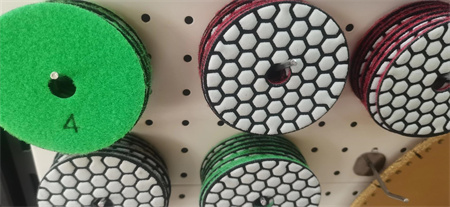

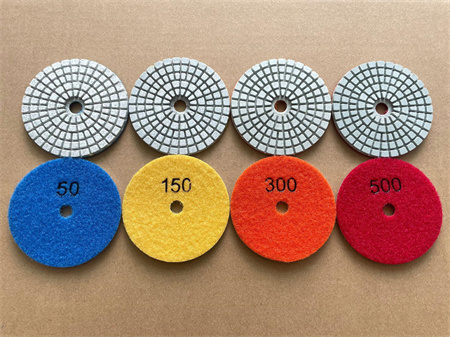

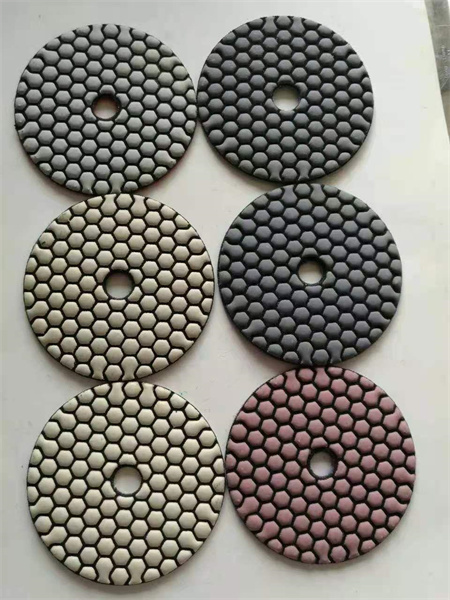

Diamond polishing pads are essential tools for achieving a smooth, glossy finish on materials like granite, marble, concrete, and more. These pads use industrial-grade diamonds to efficiently polish surfaces, making them a must-have for anyone who wants perfect results. When you buy directly from the manufacturer, you eliminate middlemen and markups, giving you access to the lowest prices available on the market.

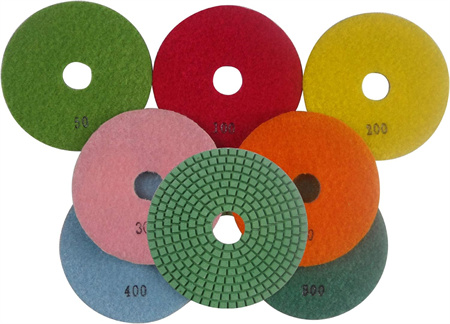

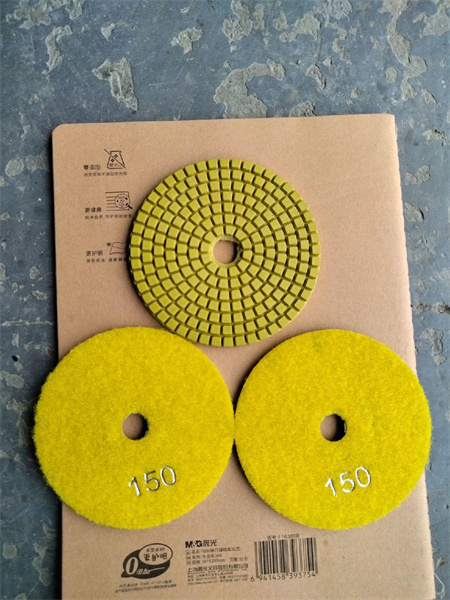

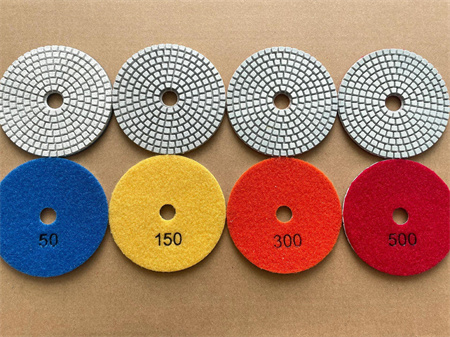

One of the biggest advantages of purchasing diamond polishing pads directly from the source is the ability to customize your order. Manufacturers often offer a range of options, from different grit sizes to various backing materials, ensuring that you can get exactly what you need for your specific project. Whether you’re working on a large-scale commercial job or a small personal project, buying directly ensures you get the right product for the job at a price that fits your budget.

Another great perk of buying direct is the opportunity to build a long-term relationship with the manufacturer. As a repeat customer, you can enjoy loyalty benefits like discounts, early access to new products, and personalized customer service. Manufacturers who sell directly to consumers typically have a deep understanding of their products and are happy to offer advice and tips to help you get the best results.

By cutting out the middleman, manufacturers can also offer faster shipping times and lower delivery costs. Whether you’re ordering in bulk or just need a few pads, you can rest assured that your products will arrive quickly and securely. Many manufacturers even offer free shipping or discounted rates on larger orders, making it even easier to stock up on the tools you need.

In today’s competitive market, having access to affordable, high-quality diamond polishing pads can make all the difference. When you buy directly from the manufacturer, you’re not only saving money, but you’re also investing in top-tier products designed to meet your needs. Don’t settle for overpriced alternatives—choose a direct manufacturer for your next order and experience the difference in quality, price, and customer service.