Granite Polishing Pads Distributor from China Factory

If you’re in the market for top-quality granite polishing pads, look no further than a trusted distributor from a reliable Chinese factory. These pads are not just ordinary products; they are a game-changer in the stone polishing industry, offering durability, efficiency, and cost-effectiveness all in one package.

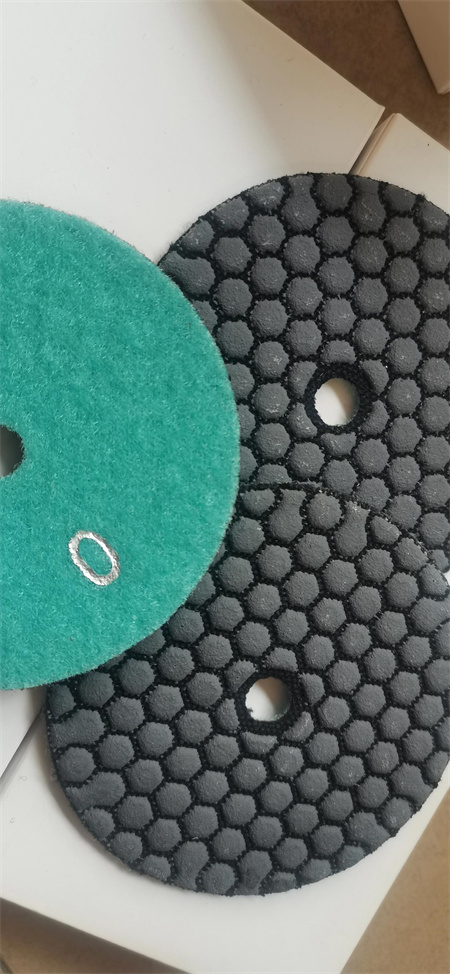

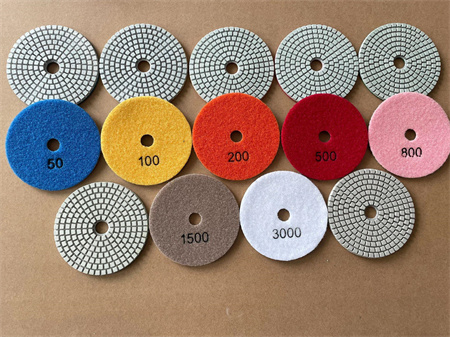

Granite, with its robust and resilient nature, requires specialized care to bring out its natural beauty. That’s where these polishing pads come in. Designed specifically for granite surfaces, they can help restore and maintain the smooth, glossy finish that granite is known for. Whether you’re working on countertops, floors, or monuments, the right polishing pad can make all the difference.

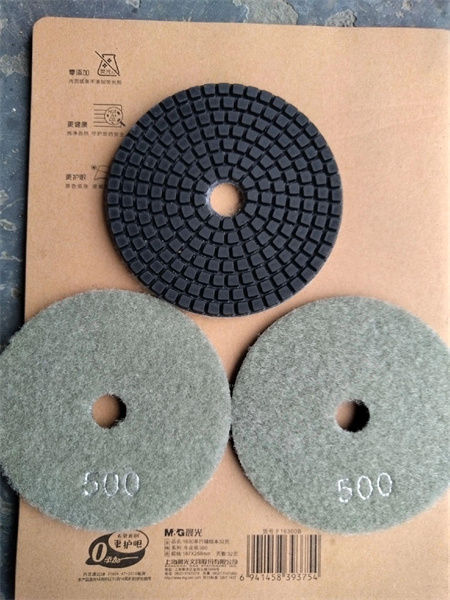

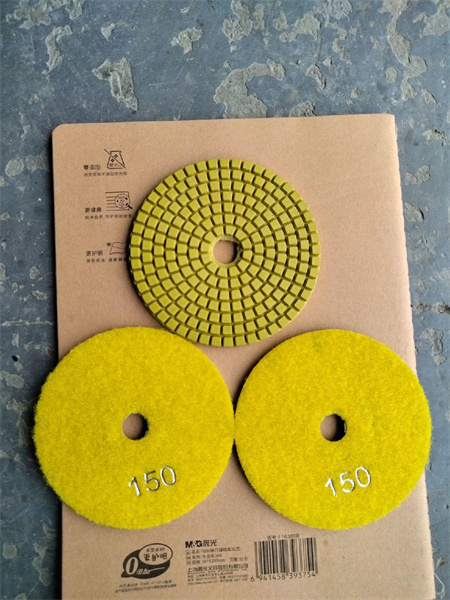

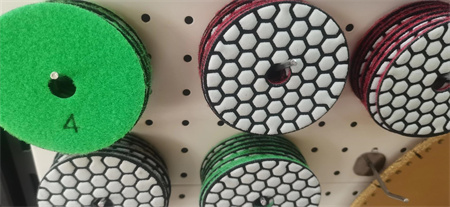

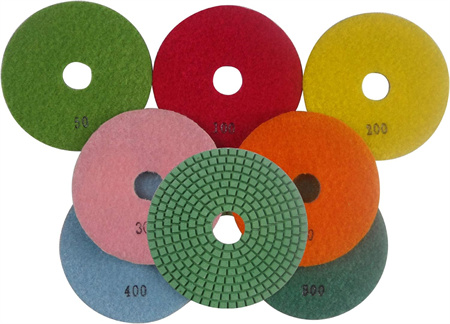

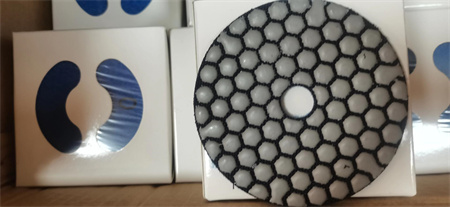

Chinese manufacturers have perfected the art of producing granite polishing pads that meet international standards. These pads are engineered using the best raw materials and innovative technology, ensuring consistent performance and superior results. The pads are available in various grit sizes, allowing you to tackle everything from rough grinding to fine polishing. This flexibility is a key factor in their popularity among professional stone fabricators and contractors.

Working with a distributor from a factory in China means you’re tapping into a vast network of suppliers who offer competitive pricing without compromising on quality. Chinese factories, renowned for their efficiency and mass production capabilities, are able to provide products at scale, making them a go-to source for large-scale operations.

The advantage of working with a reputable distributor goes beyond just cost savings. You gain access to expert advice on which pads are best suited for your specific needs. Whether you’re polishing granite for commercial projects or handling intricate residential work, the distributor will guide you in choosing the perfect pads that match your project requirements.

Furthermore, reliable distributors ensure that their products undergo rigorous quality checks before being shipped out. This attention to detail ensures that every batch of polishing pads performs consistently, giving you peace of mind that your tools will last longer and deliver the polished look you desire.

One of the most appealing aspects of sourcing granite polishing pads from a Chinese distributor is the ability to receive high-quality products at a fraction of the cost you’d expect from local suppliers. By eliminating unnecessary middlemen, these distributors are able to offer lower prices without sacrificing the standard of their products.

In conclusion, whether you’re a professional stone contractor or a DIY enthusiast, choosing a granite polishing pad distributor from a Chinese factory can provide you with the tools you need to achieve exceptional results. With their durable, high-performance pads, you’re guaranteed to enhance the appearance of any granite surface while saving time and money.