Diamond polishing pads are an essential part of the surface finishing process, particularly for industries involved in manufacturing stone, concrete, and other hard materials. For wholesale businesses looking to source high-quality products at competitive prices, finding a reliable diamond polishing pad manufacturer is crucial. These pads offer the durability and precision required to achieve a flawless finish, making them a top choice for professionals around the globe.

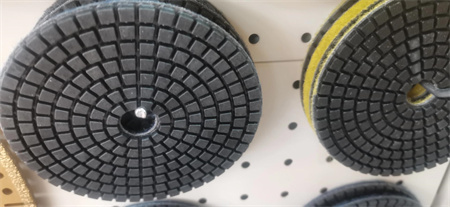

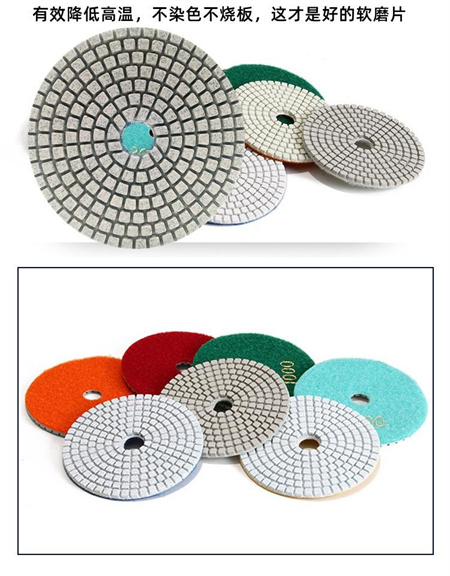

Manufacturers specializing in diamond polishing pads typically use advanced techniques and materials to ensure that their products deliver consistent performance across various applications. Whether for granite countertops, marble floors, or concrete surfaces, these pads are engineered to handle the toughest jobs without compromising quality. Their versatility makes them indispensable in both commercial and residential settings, from large construction projects to home improvement tasks.

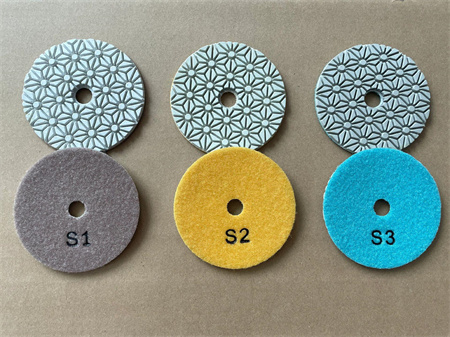

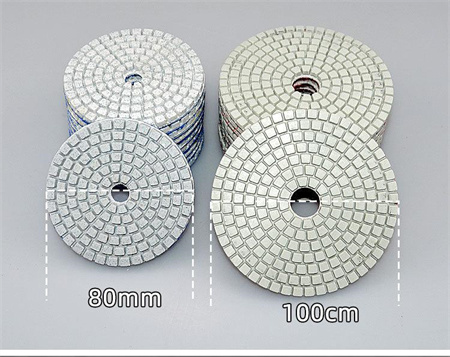

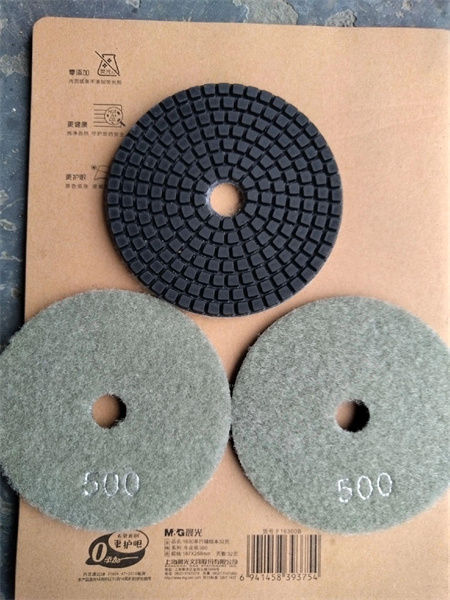

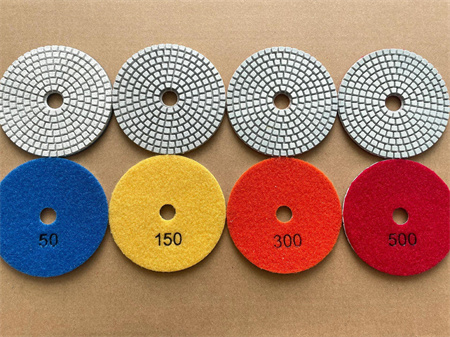

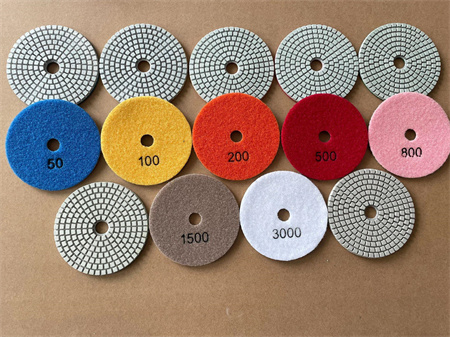

A trustworthy manufacturer understands the diverse needs of wholesale buyers. They provide a wide range of pad types, including dry and wet polishing pads, each designed to meet specific surface requirements. Dry pads, for instance, are great for quick jobs with minimal mess, while wet pads are ideal for longer polishing sessions, providing superior results and a smoother finish. Customization options are also often available, allowing businesses to choose the right grit sizes, diameters, and pad compositions suited to their customer needs.

Wholesale buyers should also consider factors like pricing, lead time, and customer service when choosing a manufacturer. A dependable diamond polishing pad supplier not only offers competitive pricing but also ensures fast delivery to meet tight project deadlines. Moreover, their customer support should be responsive and knowledgeable, ready to assist with any product inquiries or technical issues that may arise.

Investing in high-quality diamond polishing pads from a reputable manufacturer can elevate a wholesale business, providing customers with exceptional products that help them achieve professional-grade results. Whether your business serves contractors, fabricators, or DIY enthusiasts, partnering with the right supplier is essential for long-term success in the competitive market of surface finishing products.