Dry Diamond Polishing Pads Bulk Exporter China

When it comes to achieving a flawless, smooth finish on stone, concrete, or marble surfaces, dry diamond polishing pads are the go-to solution for professionals worldwide. China has emerged as one of the largest suppliers of these high-performance pads, catering to a growing demand from industries that require precision, durability, and efficiency. As a bulk exporter of dry diamond polishing pads, China is leading the way in providing top-quality products at competitive prices.

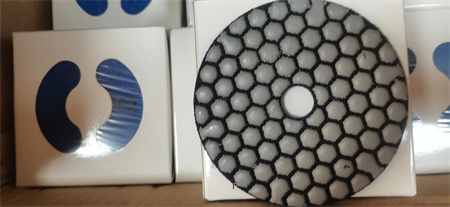

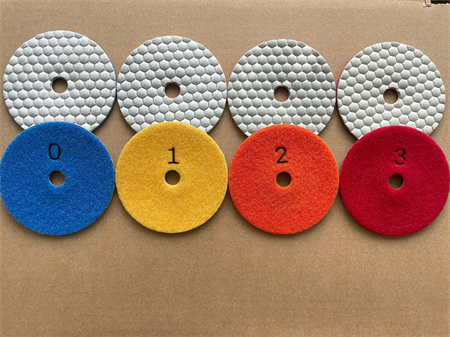

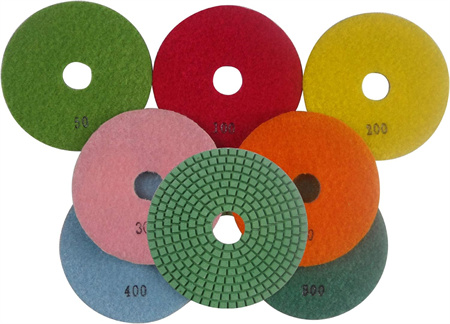

Dry diamond polishing pads are designed to work without the need for water, making them ideal for environments where moisture is not an option. Whether you’re working on a delicate marble countertop, a rugged granite floor, or a polished concrete surface, these pads are engineered to deliver an exceptional finish with minimal effort. The dry polishing method reduces mess, increases portability, and enhances the overall convenience of the polishing process.

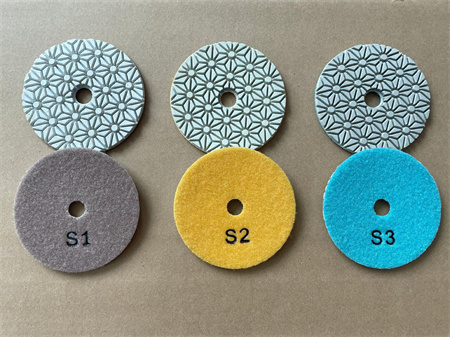

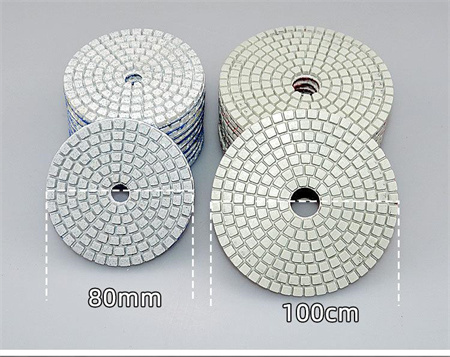

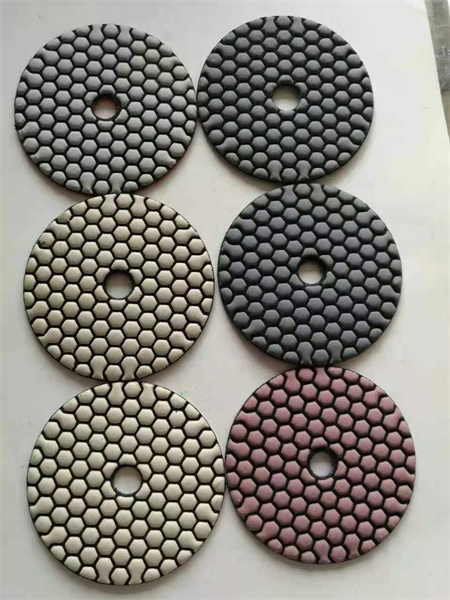

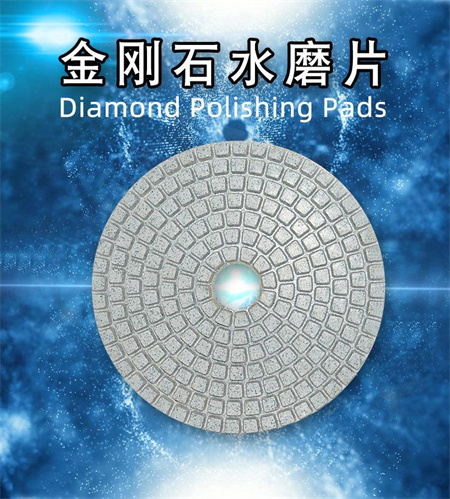

What sets China apart in this industry is the combination of innovation, technology, and expertise. Manufacturers in China have continuously improved the composition and design of diamond pads to meet the specific needs of their customers. These pads are made with high-quality synthetic diamonds embedded in a durable resin bond, ensuring long-lasting performance and a superior shine. The meticulous manufacturing process guarantees uniformity in thickness, size, and quality, providing consistency with every use.

One of the key benefits of sourcing dry diamond polishing pads in bulk from China is the cost efficiency. The sheer scale of production allows manufacturers to pass on substantial savings to their customers, making it an attractive option for businesses looking to maximize profit margins. Additionally, the high production capacity means that bulk orders can be fulfilled quickly, ensuring that customers receive their products on time without compromising on quality.

Chinese exporters are also known for their customer-centric approach, offering personalized services tailored to meet the specific needs of clients. Whether you’re a small business or a large-scale operation, these suppliers can provide customized packaging, delivery options, and after-sales support to ensure a seamless experience from order to delivery. Plus, with the ability to ship to various international markets, China-based suppliers are able to serve a global customer base, making them a reliable partner in the diamond polishing pad industry.

In conclusion, the demand for dry diamond polishing pads continues to rise, and China remains at the forefront of supplying these essential tools. With a commitment to quality, innovation, and customer satisfaction, Chinese exporters are an excellent choice for businesses looking to purchase dry diamond polishing pads in bulk. The combination of cutting-edge technology, superior craftsmanship, and competitive pricing makes China the ultimate destination for all your polishing pad needs.