Granite Polishing Pads China OEM Distributor: Quality and Durability for Your Projects

If you’re in the business of stone or granite surface processing, you know the importance of having the right tools to achieve a smooth and polished finish. Granite polishing pads are essential for ensuring that your project gets the professional look it deserves, and choosing the right distributor can make all the difference. As an OEM distributor based in China, we understand the demands of both quality and affordability, offering products designed for durability and efficiency.

Granite polishing pads are an indispensable part of the stoneworking process, whether you’re working with countertops, flooring, or monuments. They are designed to smooth and shine the rough surface of granite, removing imperfections and scratches. For many businesses, sourcing these pads from reliable manufacturers is critical to ensuring high-end results every time.

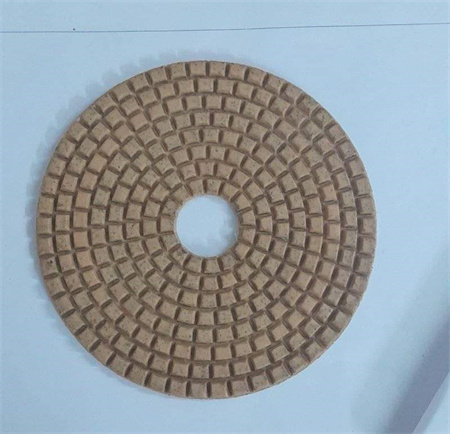

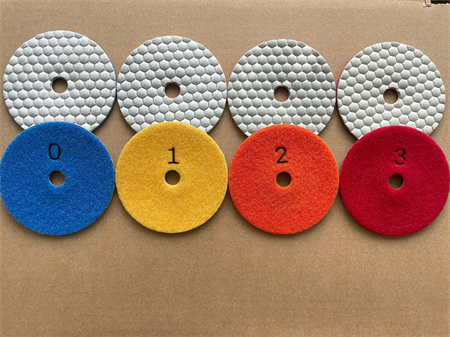

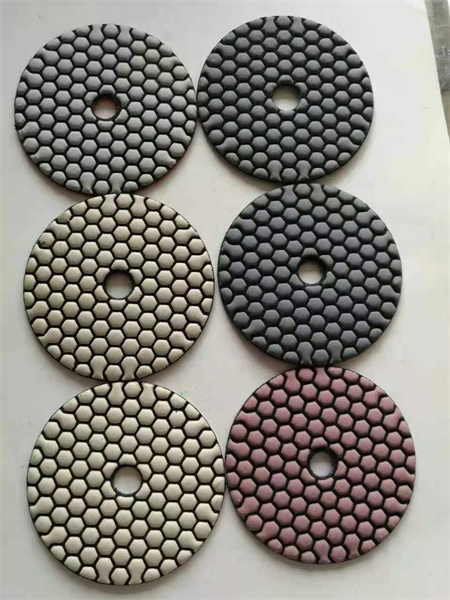

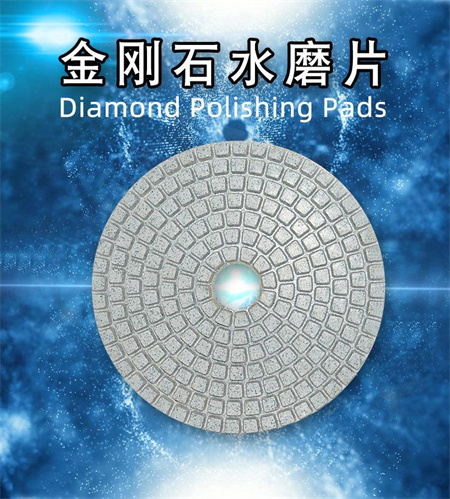

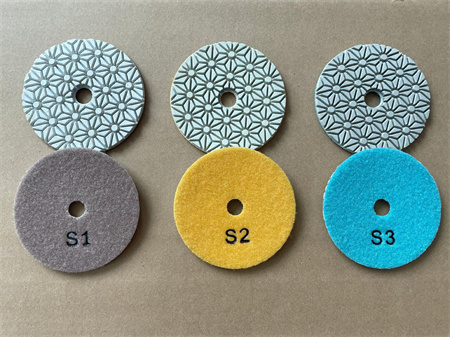

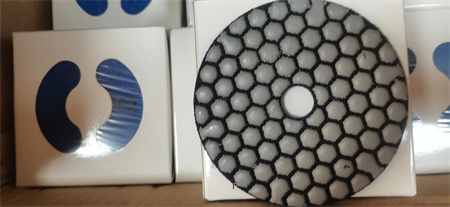

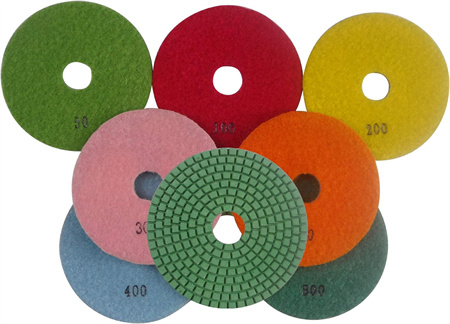

Our granite polishing pads are crafted using premium materials that ensure longevity and effectiveness. We offer a wide range of options, from resin-bonded pads to diamond polishing pads, suitable for various types of granite surfaces. Whether you’re tackling a light touch-up job or heavy-duty surface restoration, we have the tools you need.

What sets us apart from other distributors is our focus on quality control. Our products undergo stringent testing at every stage of production to guarantee that each pad delivers consistent performance. Our OEM capabilities also mean that we can tailor our pads to your specific requirements, ensuring they fit your equipment and meet the unique needs of your projects.

We know that time is money in the stone industry, so we also prioritize fast shipping and efficient customer service. Working with an OEM distributor based in China means you can access high-quality granite polishing pads at competitive prices, without compromising on performance or reliability. We aim to be a partner you can count on, providing excellent products that help your business thrive.

For businesses looking to streamline their operations or expand their product offerings, choosing the right distributor for granite polishing pads is crucial. With our extensive experience and commitment to quality, we offer a seamless and cost-effective solution for all your stone polishing needs.

Reach out today to learn more about our products, and find out why we are the go-to OEM distributor for granite polishing pads in China!