The History of Diamond Polishing Tools in Construction

Diamond polishing, often associated with the luxury of gleaming marble floors or perfectly smooth countertops, actually dates back thousands of years. The early use of diamonds for polishing and cutting is rooted in ancient civilizations. While the diamond itself was known for its strength and beauty, it was not until much later that its practical uses in construction began to take off. Early cultures like the Egyptians and Romans utilized crude forms of diamond dust or grit to polish stones and metals. However, it was not until the industrial revolution that the full potential of diamond abrasives would be unlocked for the construction industry.

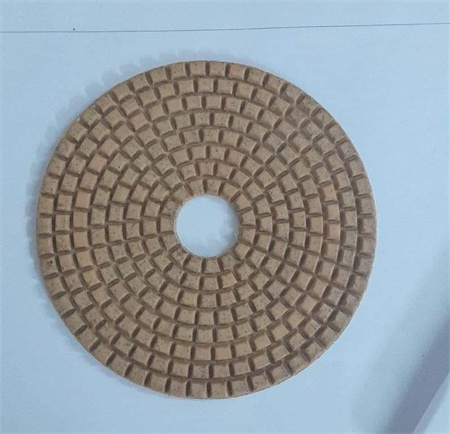

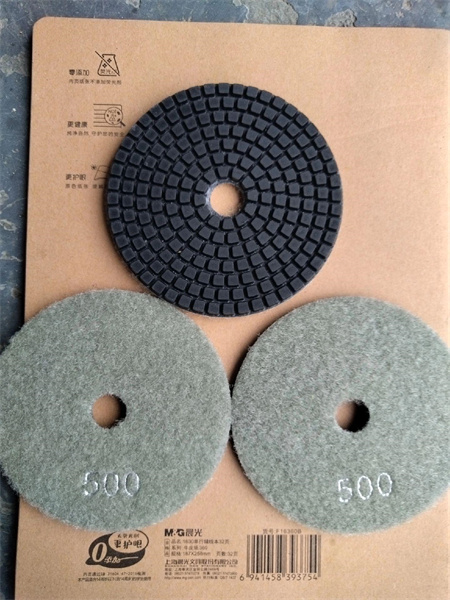

The true breakthrough in diamond polishing tools for construction came with the invention of the diamond polishing pad in the mid-20th century. These pads were designed specifically for the construction industry, where precision and a flawless finish were increasingly demanded. Initially, these pads were bulky and expensive, making them accessible only to high-end contractors and specific industries. However, as manufacturing techniques improved and demand for high-quality finishes grew, diamond polishing tools became more affordable and widely available.

One of the major developments in the diamond polishing tool industry was the invention of the segmented diamond tooling. This innovation allowed for more efficient material removal and smoother finishes on hard surfaces. Segmented diamond tools featured diamond segments mounted on a metal core, allowing them to be used on concrete, granite, marble, and other tough materials with increased speed and consistency. Over time, these tools were refined, and manufacturers began to offer diamond polishing pads in different grits to cater to various stages of the polishing process, from rough grinding to fine finishing.

With advancements in technology, diamond polishing tools became even more specialized. In the late 20th and early 21st centuries, the rise of computer-controlled equipment and robotic machinery further refined the use of diamond tools in construction. These tools were integrated into automated systems, improving consistency and efficiency in the polishing process. This also allowed for intricate designs and patterns to be embedded into surfaces, opening new avenues for artistic expression within the construction industry.

The versatility of diamond polishing tools has expanded far beyond flooring and countertops. Today, they are essential in polishing and finishing materials used in the creation of sophisticated facades, decorative tiles, and even sculptures. Diamond tools are also used in the maintenance and renovation of old buildings, where preserving the original surface quality while restoring its appearance is paramount.

At the heart of the widespread adoption of diamond polishing tools is their exceptional durability. Unlike traditional abrasives, diamond tools maintain their effectiveness over long periods, making them ideal for heavy-duty construction projects. Contractors and builders no longer need to worry about the constant replacement of polishing tools, which translates into both cost savings and time efficiency. The durability of diamonds ensures that they can handle the most challenging tasks, whether it’s polishing the hardest natural stones or smoothing out rough concrete floors.

In the present day, diamond polishing tools continue to evolve with the latest advancements in materials science and engineering. Manufacturers are constantly developing new types of diamond abrasives, optimizing the performance of their products for a range of surfaces and applications. Environmental concerns and sustainability have also played a role in the development of diamond polishing tools, with an increasing focus on eco-friendly practices and energy-efficient machinery.

The journey of diamond polishing tools in construction reflects not only technological advancements but also a growing understanding of the importance of surface quality in modern architecture and design. These tools have become indispensable in delivering the high standards expected by both clients and architects. As construction technology continues to advance, one can only imagine the new possibilities that will emerge, with diamond tools leading the way in precision, quality, and innovation.

From their humble beginnings to their current status as a cornerstone of construction, diamond polishing tools have proven that sometimes the most refined solutions come from the hardest materials. The history of these tools is a testament to the power of innovation and the desire for perfection in every aspect of construction.