Diamond Polishing Pads for Global Hardware Retail Stores

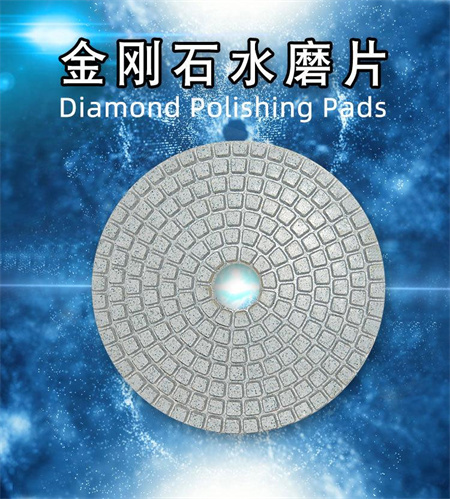

In the competitive world of hardware retail, staying ahead means offering the best products for every job, big or small. One such product that continues to rise in popularity among both professionals and DIY enthusiasts is diamond polishing pads. These specialized tools are a must-have for anyone working with stone, concrete, marble, or granite. Whether you’re looking to maintain a smooth, glossy finish or restore the shine of a worn surface, diamond polishing pads deliver exceptional results.

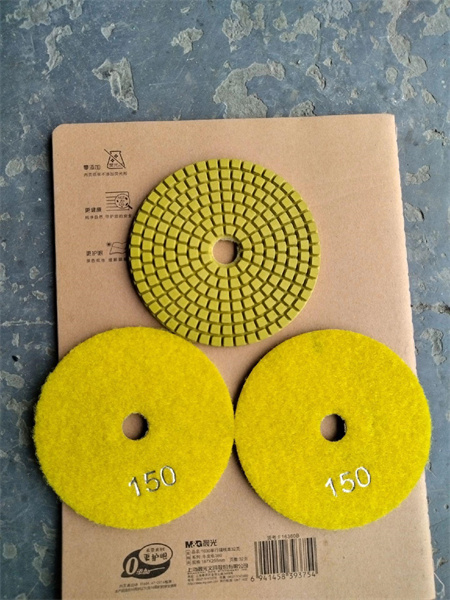

What sets diamond polishing pads apart is their durability and performance. Unlike traditional abrasives, which can wear out quickly, these pads are designed to withstand heavy use. The diamond particles embedded in the pad are incredibly hard, allowing them to cut through tough materials with ease, making them ideal for polishing hard surfaces that other materials just can’t handle. With the right polishing pad, even the roughest surfaces can be transformed into a smooth, lustrous finish.

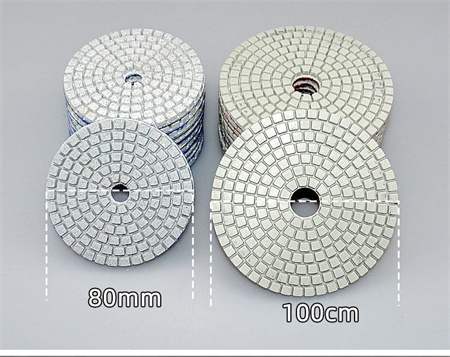

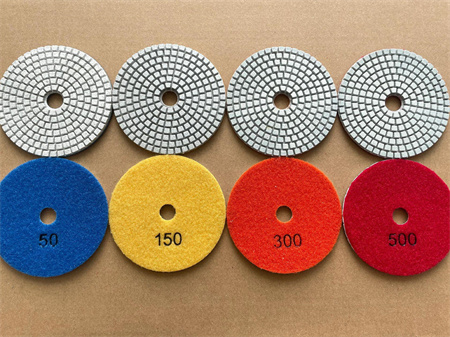

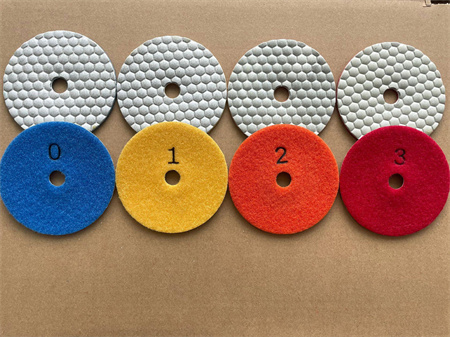

For global hardware retail stores, stocking diamond polishing pads means catering to a wide range of customers, from home improvement enthusiasts to professional contractors. The variety available ensures that no matter the job, there’s a pad suited for the task. Pads come in different grits, allowing customers to choose the perfect level of abrasiveness for their needs. Whether it’s for heavy-duty grinding or a delicate, fine polish, there’s a pad for every application.

One of the key benefits for retailers is the growing demand for these products. As more people take on DIY home projects and as the construction industry continues to thrive, the need for high-quality finishing tools like diamond polishing pads will only increase. By offering these products, hardware stores not only meet the needs of their customers but also position themselves as the go-to destination for premium quality tools that deliver professional-grade results.

The market for diamond polishing pads is global, and the demand continues to expand. With the right marketing strategy, hardware retailers can tap into this lucrative market, offering products that are both high in demand and essential for a wide range of applications. As technology continues to evolve and the demand for superior finishes grows, investing in diamond polishing pads will only add to a hardware store’s reputation for providing top-tier tools.

In a market where quality and reliability are king, stocking diamond polishing pads is a smart move. For both retailers and consumers, these pads offer an unbeatable combination of performance, versatility, and value.