Diamond Polishing Pads Trends in International Trade

The international trade of diamond polishing pads has been experiencing rapid growth, fueled by the increasing demand for high-quality surface finishing in industries ranging from construction to electronics. These pads, designed to provide a flawless, smooth finish to various surfaces, are now a critical tool in processes that require precision and durability. As global markets continue to evolve, the trends shaping the diamond polishing pad industry reflect a broader shift towards innovation, sustainability, and cost-efficiency.

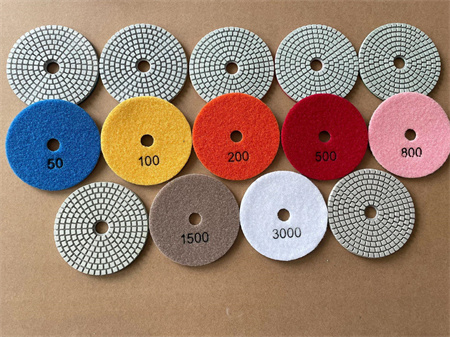

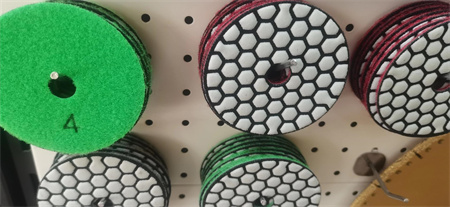

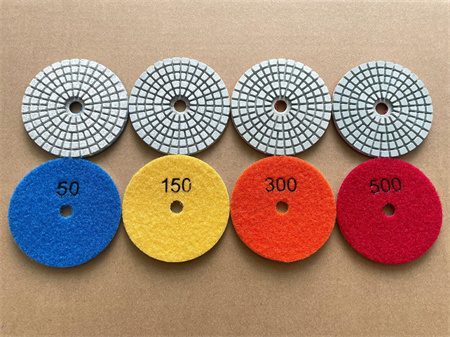

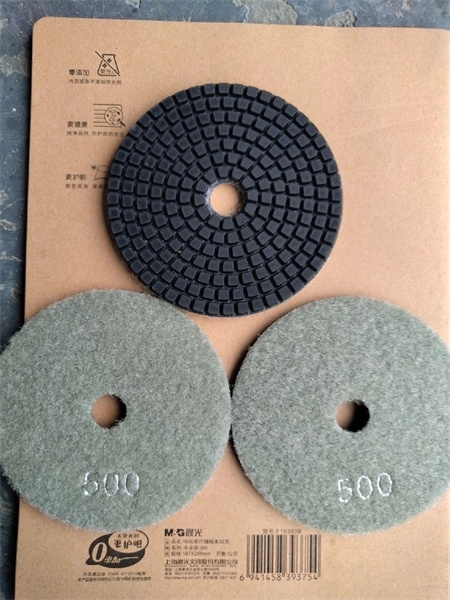

One of the most prominent trends in the diamond polishing pad market is the rising emphasis on product performance. Manufacturers are constantly pushing the boundaries of technology, creating pads that offer enhanced durability and longer life spans. With the construction sector demanding faster, more efficient solutions for polishing marble, granite, and concrete, these innovations are paving the way for the future of surface finishing. The focus is not just on the appearance of the finished surface, but also on reducing the overall time and energy spent on polishing tasks.

Another trend that cannot be ignored is the growing importance of sustainability in the manufacturing process. With environmental concerns on the rise, more companies are shifting towards eco-friendly alternatives in their production lines. Non-toxic binders, reduced chemical usage, and recyclable materials are becoming standard practices. This aligns with the global push for greener manufacturing practices, especially in regions where environmental regulations are becoming more stringent. Sustainable diamond polishing pads are increasingly in demand, as both consumers and businesses become more conscious of their environmental impact.

Additionally, the rise of digitalization and automation is transforming how diamond polishing pads are produced and sold. The integration of Artificial Intelligence (AI) and Machine Learning (ML) into manufacturing processes allows for higher precision and better control over the production line. This level of automation helps manufacturers reduce errors and minimize waste, further contributing to the industry’s push towards cost-effectiveness. On the trade front, e-commerce platforms and digital marketing are playing a larger role in expanding the reach of diamond polishing pad suppliers. Online marketplaces are not only enabling easier access to global markets but also facilitating faster transactions and smoother logistics.

The Asia-Pacific region continues to be the dominant player in the global diamond polishing pad market, with countries like China, India, and Japan leading the charge in both production and consumption. However, emerging markets in the Middle East, Latin America, and Africa are quickly catching up, thanks to rapid urbanization and increasing investments in infrastructure projects.

In conclusion, the future of diamond polishing pads in international trade is one of innovation, sustainability, and efficiency. As the demand for high-performance products increases across various sectors, manufacturers are adapting to meet the challenges of an ever-evolving market. Whether it’s through the adoption of green technologies or the integration of cutting-edge digital tools, the industry is well-positioned for continued growth and success on the global stage.