Marble polishing disc OEM manufacturer for countertop fabrication companies

If you’re in the business of countertop fabrication, you know how essential it is to provide high-quality finishes that leave your customers in awe. One of the crucial elements in achieving that perfect finish is the right polishing disc. That’s where a reliable OEM manufacturer of marble polishing discs can make all the difference.

Marble is a timeless material that adds elegance and sophistication to any space, whether it’s for kitchens, bathrooms, or luxury commercial projects. But to ensure marble surfaces look their best, the right polishing tools are needed to enhance their natural beauty. As a countertop fabrication company, partnering with a trusted OEM manufacturer allows you to access polishing discs that are tailored to your specific needs, whether you’re working on intricate edges or large surfaces.

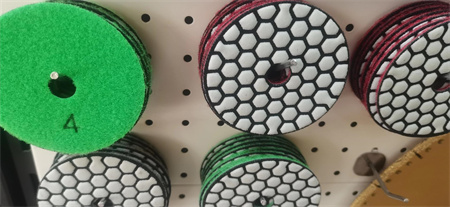

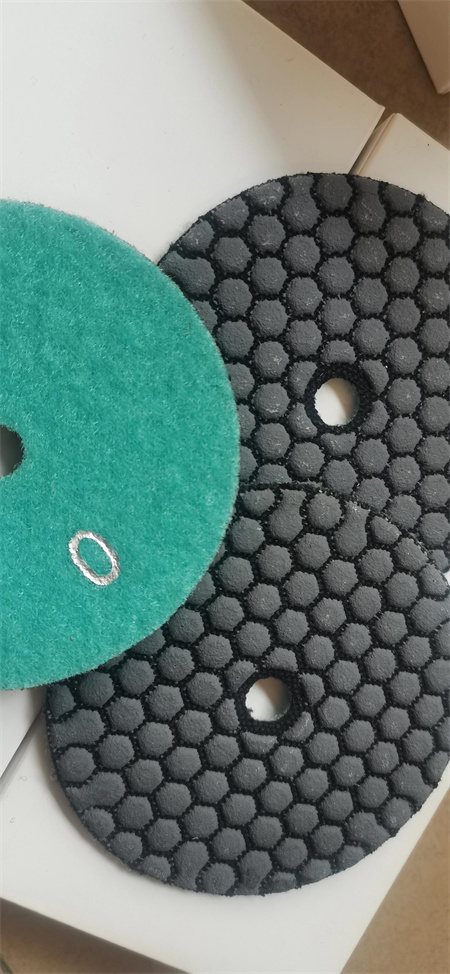

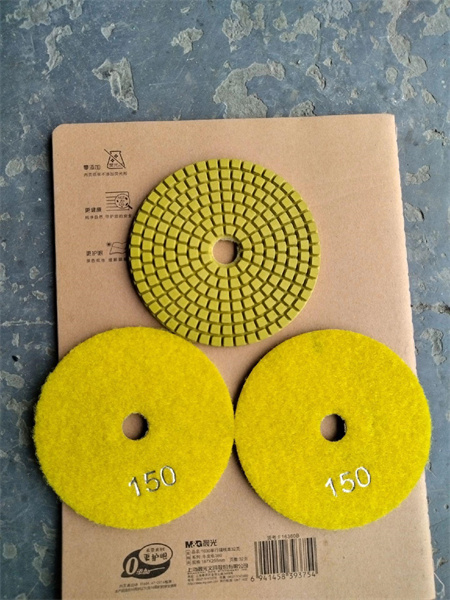

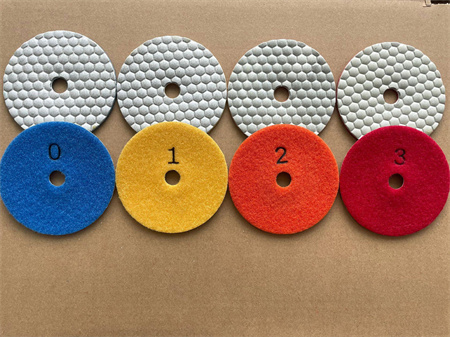

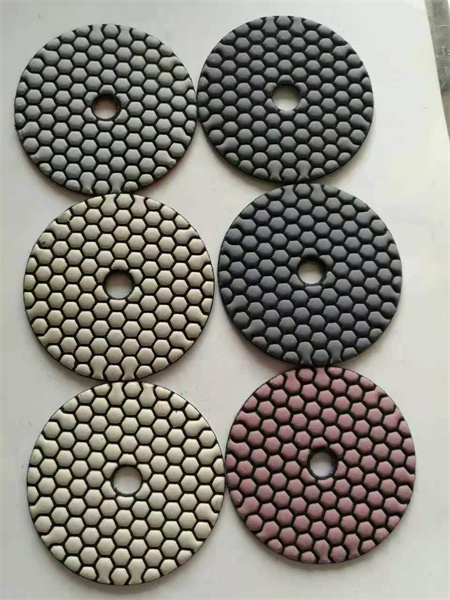

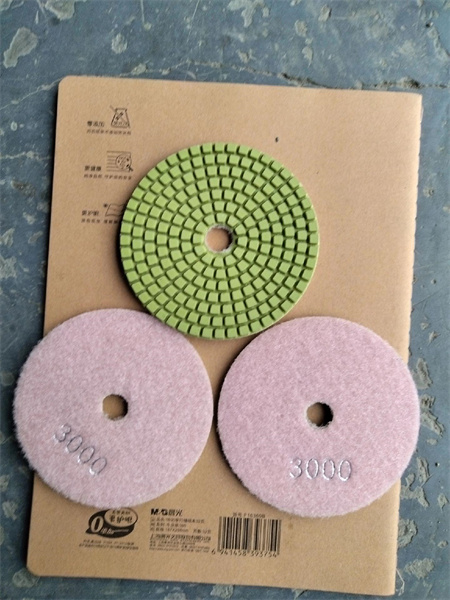

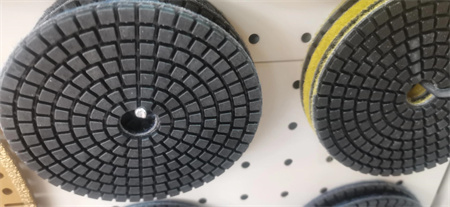

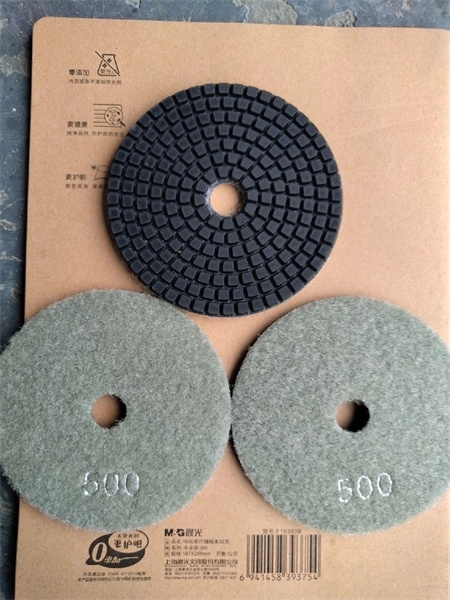

When choosing an OEM manufacturer, it’s essential to consider the quality of the discs and their compatibility with different polishing machines. A good manufacturer will offer discs made from durable materials that can withstand heavy use while providing a smooth, high-gloss finish that lasts. The right disc ensures that the marble’s surface remains flawless, without any unsightly marks or scratches.

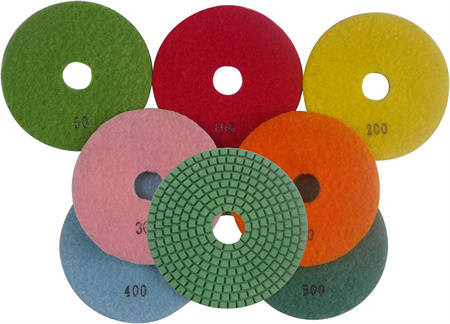

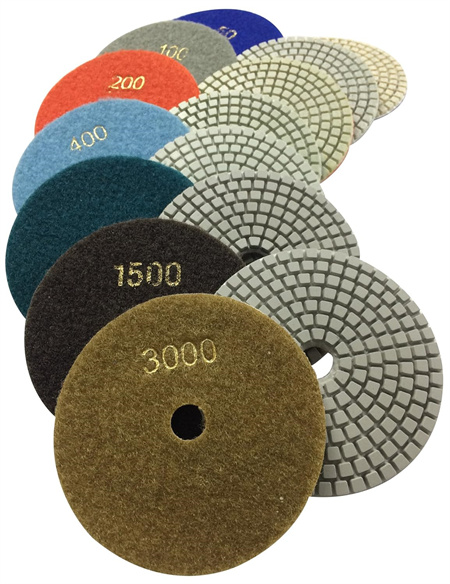

Another key factor to keep in mind is the manufacturer’s ability to customize polishing discs. Different projects may require specific grit levels or specialized designs, and a good OEM partner will be able to create discs that meet your unique specifications. Customization ensures you have the tools needed to achieve perfection, no matter the marble variety or complexity of the job.

Beyond the performance of the discs, you also want a manufacturer that prioritizes consistency and reliability in their production process. A reliable OEM will deliver discs that are uniform in size, shape, and performance, helping you avoid any inconsistencies in your final product. This consistency helps maintain the reputation of your countertop fabrication business as one that delivers nothing short of excellence.

Building a relationship with a marble polishing disc OEM manufacturer isn’t just about securing high-quality tools for your work; it’s about creating a partnership that supports your business growth. Whether you’re tackling small-scale residential projects or large commercial jobs, the right polishing discs can elevate the quality of your marble surfaces and keep your customers coming back for more.

In today’s competitive market, investing in premium polishing discs can set your business apart. Choose a trusted OEM manufacturer to ensure that your countertop fabrication projects always shine with the best marble finish possible.