Buy Diamond Polishing Pads Wholesale for Importers

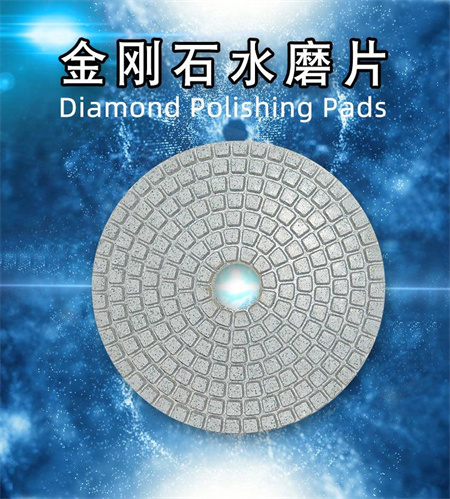

If you’re an importer looking to stock up on high-quality diamond polishing pads, you’re in the right place. Diamond polishing pads are essential tools for professionals in various industries, including construction, stone cutting, and glass processing. These pads are specifically designed to give surfaces a smooth, polished finish, and buying them in bulk can help you save money and ensure you have enough stock to meet demand.

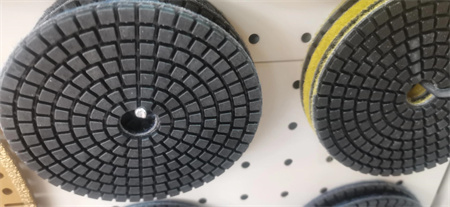

The demand for diamond polishing pads continues to rise, and for good reason. These pads are perfect for polishing a wide range of materials, from granite and marble to concrete and glass. They can also be used for polishing floors, countertops, and other stone surfaces, making them versatile tools for many different industries. With a wholesale purchase, you can offer these pads to customers who rely on them for their daily operations.

One of the main advantages of purchasing diamond polishing pads wholesale is the cost-effectiveness. When you buy in bulk, you get better pricing, which means you can pass on those savings to your customers. It’s also a convenient option for importers, as it ensures you always have a steady supply of these essential tools. Whether you’re running a business that serves small contractors or large-scale operations, having diamond polishing pads on hand will never go out of style.

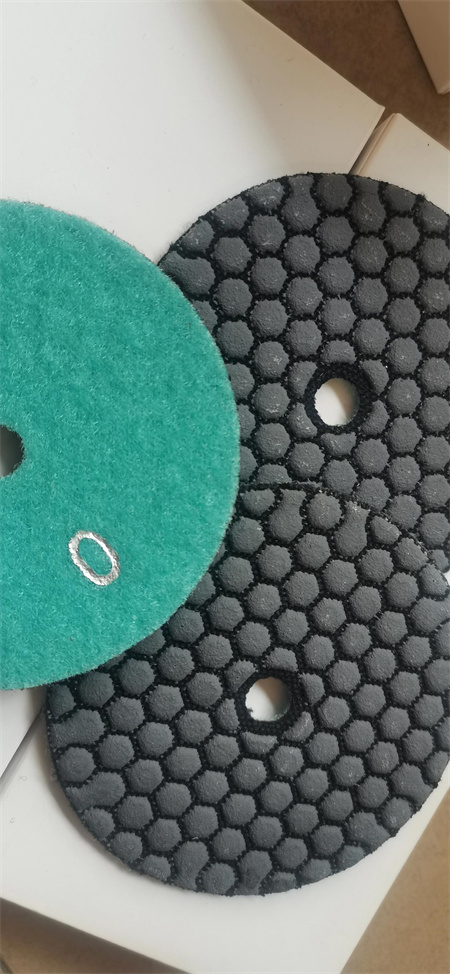

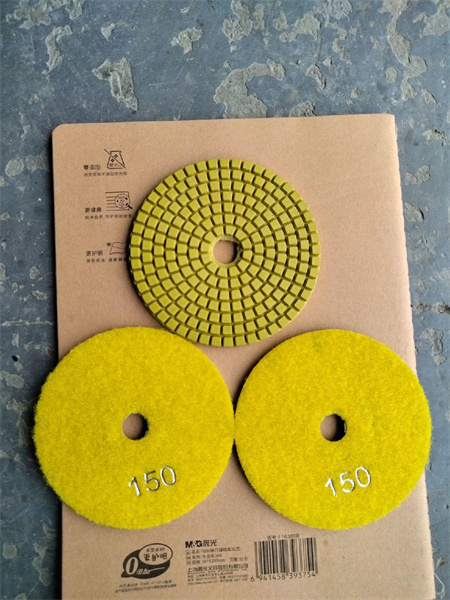

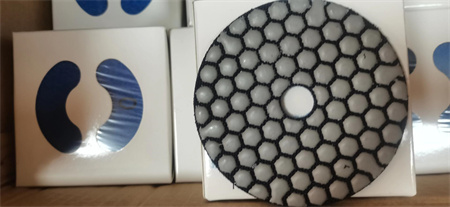

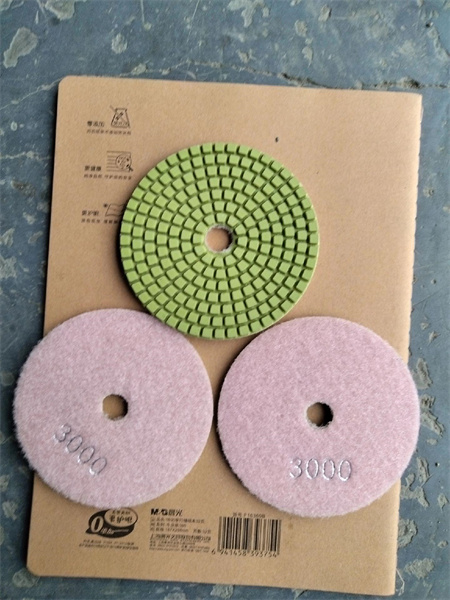

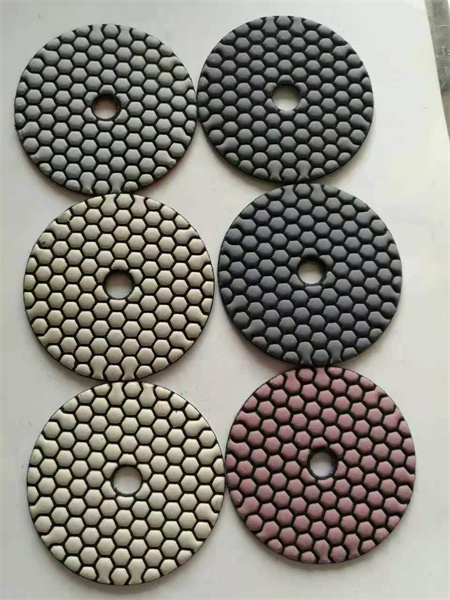

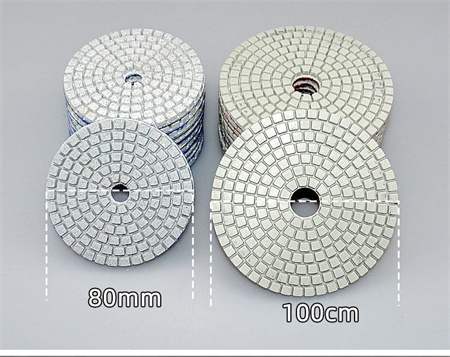

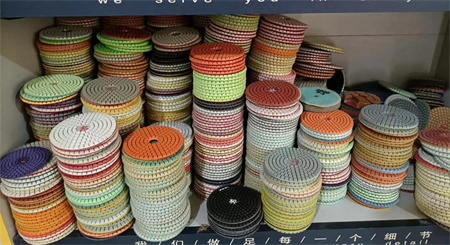

Additionally, wholesale suppliers often offer a variety of pad types, so you can choose the right ones for your specific needs. From coarse pads designed for heavy-duty jobs to finer pads for finishing touches, you’ll find products that suit different applications. Plus, many suppliers offer customizable solutions, such as pads with varying grit levels or those designed for specific types of stone. This means you can cater to a wider customer base and offer them exactly what they need.

Choosing the right supplier is also key. Look for one with a solid reputation in the industry, known for delivering high-quality products and excellent customer service. A good supplier should offer a guarantee on their products, so you can be confident in the longevity and effectiveness of the pads you purchase. As an importer, it’s important to establish a reliable partnership with suppliers that understand the demands of the market and are able to meet them efficiently.

In conclusion, buying diamond polishing pads wholesale for importers is not only a smart business move, but it’s also an investment in your company’s success. With the right products and suppliers, you can meet the ever-growing demand for these essential tools while maintaining a competitive edge in the market. Don’t miss out on this opportunity to enhance your business and offer quality products to your customers.