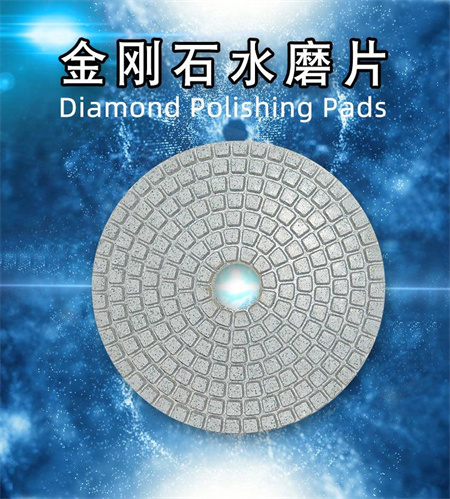

Diamond Polishing Pads Export Opportunities in the Middle East

The Middle East has long been known for its booming construction, industrial, and manufacturing sectors. As the region continues to develop, so does its demand for high-quality tools and materials that can enhance efficiency and precision. One such product seeing a rise in demand is diamond polishing pads – a key tool used for achieving flawless finishes on a variety of surfaces. For exporters looking to tap into the Middle Eastern market, the opportunity is ripe for expansion.

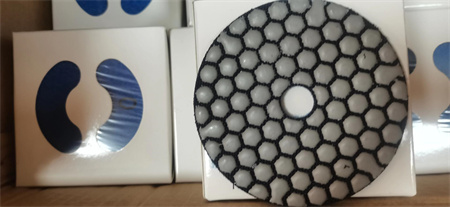

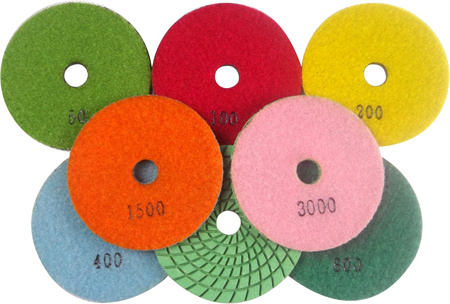

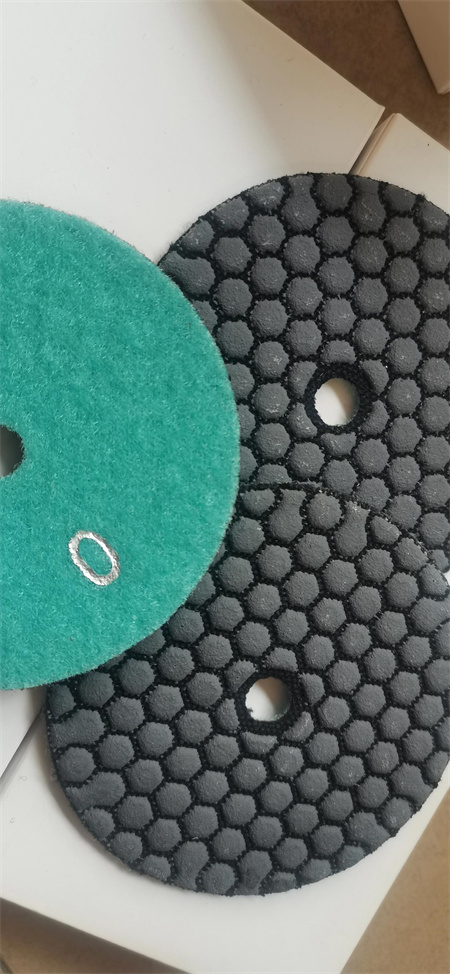

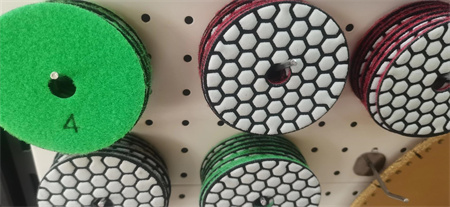

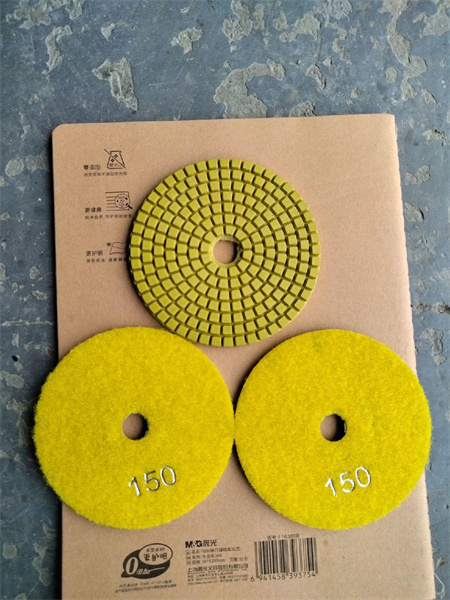

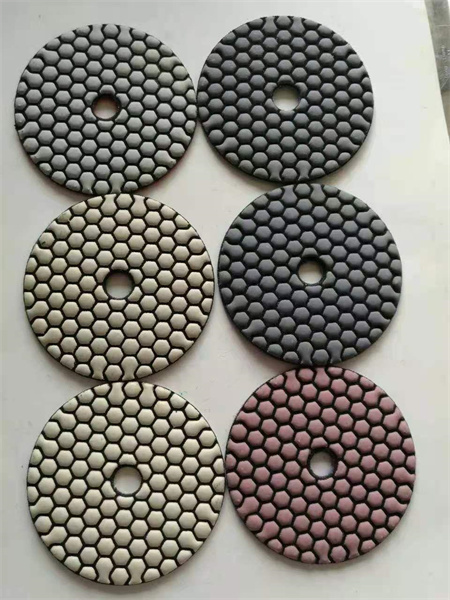

Why is the demand growing so rapidly? The Middle East is experiencing a surge in construction projects, from towering skyscrapers to luxurious residential complexes and massive infrastructure projects. As the construction industry thrives, the need for materials like marble, granite, and concrete increases. These surfaces require specialized care, and diamond polishing pads are the perfect solution for smooth, high-quality finishes.

Another driving factor is the booming automotive and electronics industries in the region. The precision and durability of diamond polishing pads make them essential for achieving the high-quality surfaces needed in car manufacturing and electronics assembly. These industries have set the bar high for product quality, and diamond polishing pads are meeting the challenge head-on.

For businesses that specialize in exporting, the Middle East offers a wealth of opportunities. Countries like the UAE, Saudi Arabia, and Qatar are investing heavily in their construction and industrial sectors, presenting a growing market for diamond polishing pads. These nations are home to some of the world’s largest construction projects, which require a steady supply of premium materials. With the right marketing strategy and reliable distribution channels, exporters can find success in meeting this demand.

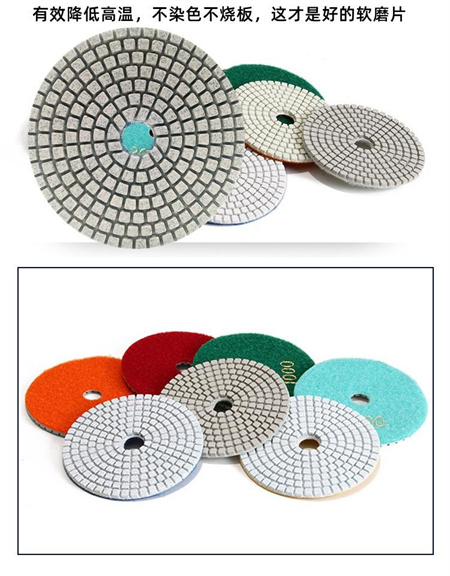

Establishing partnerships with local distributors or entering into joint ventures can be an effective way to gain a foothold in the Middle Eastern market. These relationships provide invaluable insights into local preferences and regulations, helping to build brand credibility and expand market reach. Additionally, showcasing the versatility of diamond polishing pads, from marble floors to granite countertops, could attract a wider range of customers.

The increasing awareness of quality craftsmanship in the region is also playing a role in elevating the demand for diamond polishing pads. More contractors and manufacturers are seeking tools that provide consistent results and long-lasting durability. As these industries continue to grow, so too will the need for top-tier products that ensure perfection in every project.

In conclusion, the Middle East is a market brimming with opportunities for diamond polishing pad exporters. With the ongoing growth in construction, automotive, and electronics industries, the demand for high-quality surface finishing tools is expected to soar. By leveraging the right strategies and establishing solid partnerships, businesses can successfully tap into this rapidly expanding market.