Looking for high-quality stone finishing tools for your terrazzo and concrete flooring projects? Choosing the right tools can make all the difference when it comes to achieving that perfect, polished finish on your floors. Whether you’re working on a commercial or residential project, the tools you use are essential to getting the job done efficiently and effectively.

Stone finishing tools are designed to help contractors, builders, and DIY enthusiasts create smooth, durable surfaces that will stand the test of time. With the right tools, terrazzo and concrete floors can look sleek, modern, and pristine—without the hassle of labor-intensive methods. From grinding to polishing, having the best equipment in your hands ensures that your floor finishes are not only visually appealing but also built to last.

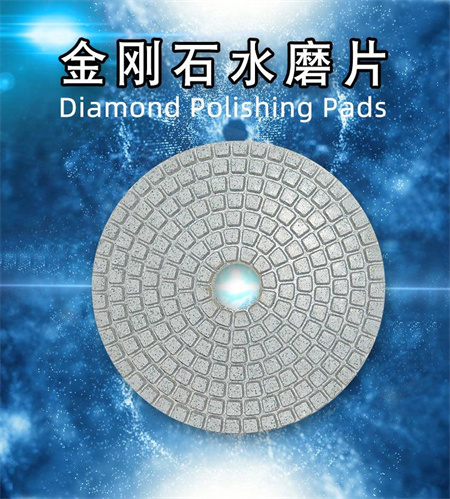

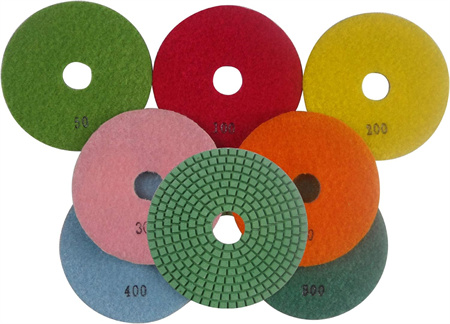

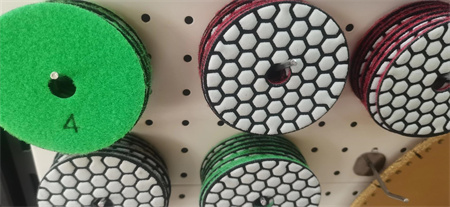

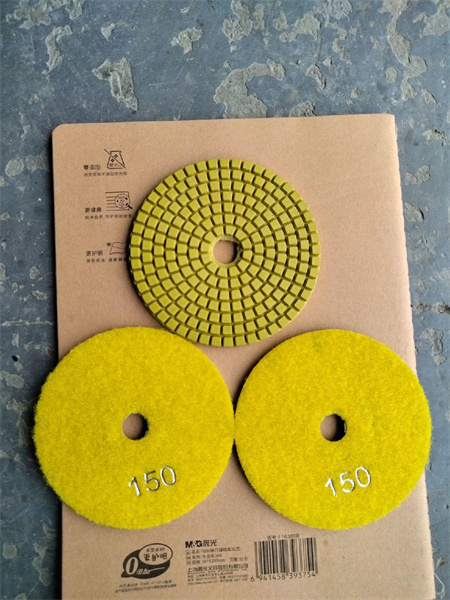

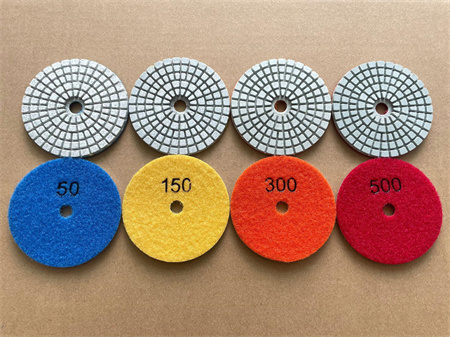

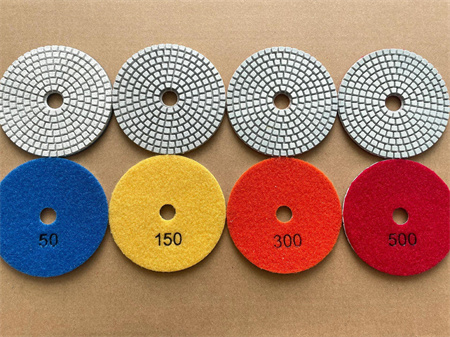

A wide variety of tools are available, depending on the scope of your project. Diamond grinding pads, for instance, are ideal for leveling rough surfaces and removing imperfections from terrazzo and concrete. These high-performance pads are designed to deliver exceptional results while minimizing the risk of surface damage. For fine finishing, a set of polishing tools that provide a smooth, glossy shine can elevate the overall look of your flooring.

When selecting a stone finishing tool supplier, it’s important to focus on quality and reliability. You want tools that can handle demanding tasks while providing consistency throughout your work. A trusted supplier will offer products that stand up to tough working conditions, while also delivering excellent value for money.

Top suppliers often provide a range of specialized tools, including concrete floor grinders, terrazzo polishing machines, and handheld polishers. These tools not only help improve the surface finish but also increase productivity, allowing contractors to complete their projects faster. The availability of both manual and electric options gives you the flexibility to choose the right equipment for your specific needs, whether you’re working in tight spaces or tackling large, expansive floors.

In addition to the tools themselves, a good supplier will also offer expert advice and support. Whether you’re unsure about which tool to pick or need guidance on maintenance, reliable customer service is a huge benefit. Experienced professionals can guide you through the process, helping you select the best products for your project and ensuring you get the most out of your investment.

So, if you’re ready to take your terrazzo or concrete flooring project to the next level, make sure to partner with a reputable stone finishing tools supplier. With the right tools and expert support, you can create stunning, long-lasting floors that will leave a lasting impression.