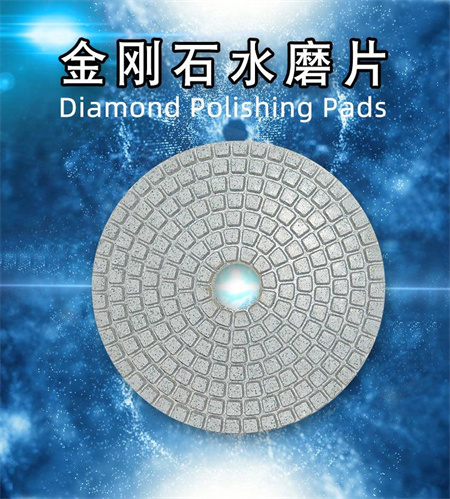

Looking to buy high-quality polishing pads? Finding a reliable supplier is key to ensuring that your products deliver the best results. A professional manufacturer from China offers a wide range of polishing pads that cater to various needs, whether you’re polishing cars, marble surfaces, or electronics.

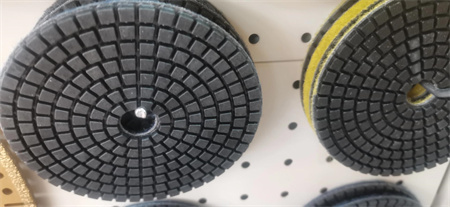

Chinese manufacturers have earned a reputation for producing durable, efficient, and cost-effective polishing pads. Their attention to detail and commitment to quality make them a go-to choice for customers worldwide. By choosing a professional manufacturer, you gain access to products made with advanced technology and superior materials, ensuring your polishing process runs smoothly and effectively.

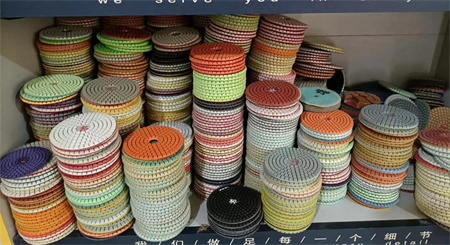

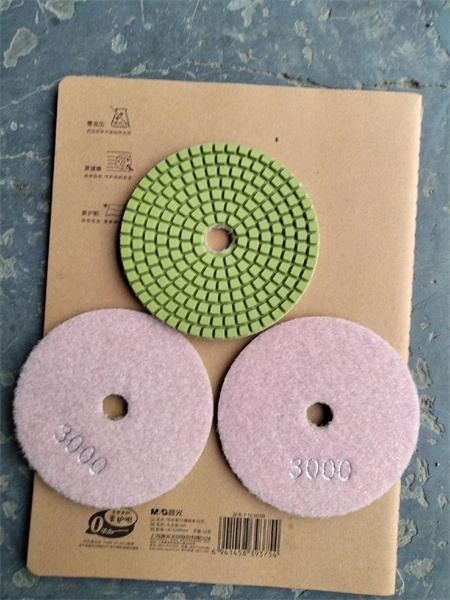

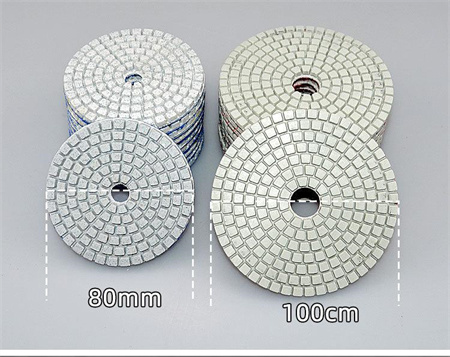

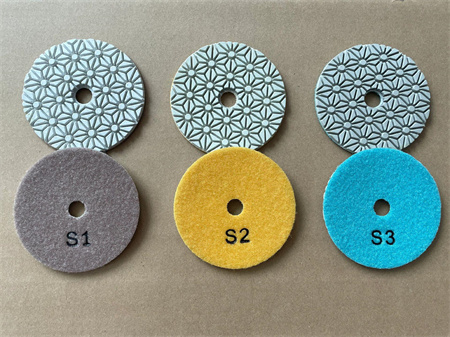

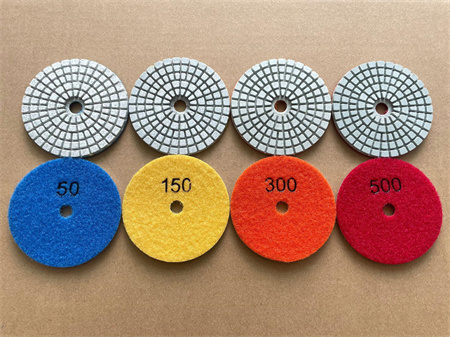

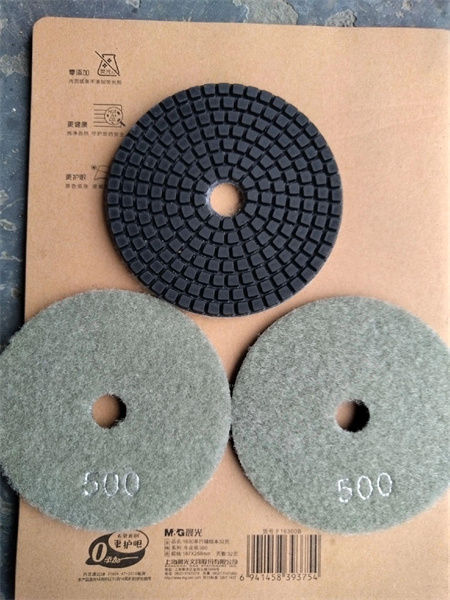

One of the advantages of buying from China is the ability to customize polishing pads based on specific requirements. Whether you need different sizes, shapes, or materials, a professional manufacturer can create polishing pads tailored to your business’s needs. This level of customization guarantees that you will get a product that fits your exact specifications, maximizing efficiency and performance.

Moreover, working directly with a manufacturer allows for better control over the production process. With open communication, you can discuss the product’s design, quality control standards, and delivery schedules to ensure that everything aligns with your expectations. Chinese manufacturers have strong logistical capabilities, which means you’ll receive your polishing pads promptly and at competitive prices.

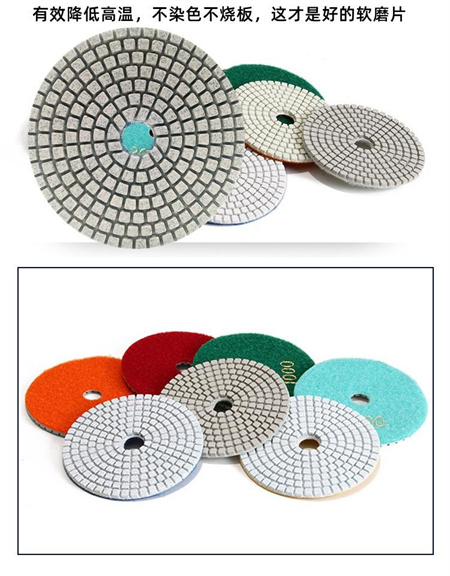

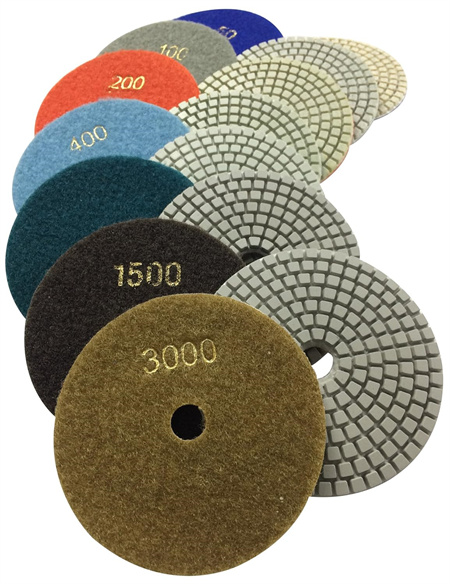

In addition to quality and customization, these manufacturers are experts in various types of polishing applications. Whether you’re looking for soft pads for delicate finishes or more aggressive ones for heavy-duty work, you’ll find the right pad for the job. The versatility of the products ensures that no matter the industry, you can rely on their effectiveness and durability.

When you choose a professional Chinese manufacturer for your polishing pads, you’re not just investing in a product—you’re building a partnership with a trusted supplier that understands your needs. With their expertise, you can be confident that your polishing tasks will be completed with precision and efficiency.