Title: Diamond Polishing Pad Supplier Direct From Factory

If you’re in the market for high-quality diamond polishing pads, there’s no better choice than getting them directly from a factory supplier. Why? The answer is simple—when you work directly with a factory, you’re cutting out the middleman, which means you get top-tier products at unbeatable prices. No added costs, no inflated fees, just the finest diamond polishing pads available, straight from the source.

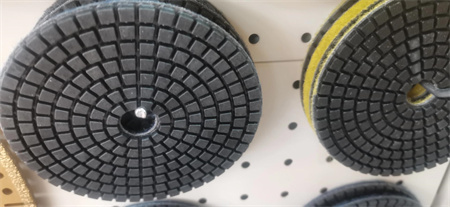

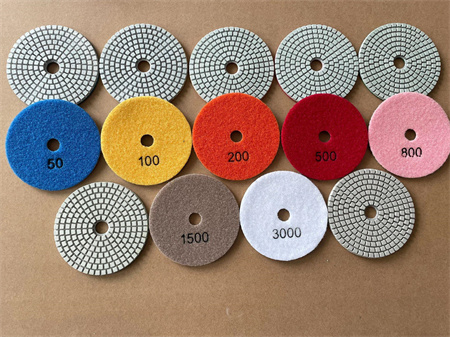

Diamond polishing pads are a must-have for anyone in the stone, concrete, or floor grinding industry. Whether you’re working with granite, marble, concrete, or other hard surfaces, these pads are designed to deliver superior results, providing a smooth, polished finish that enhances the natural beauty of the material. When sourced directly from a factory, you can trust the consistency and quality of the pads you receive, ensuring your projects turn out flawless every time.

Working with a direct supplier also means that you have access to the latest innovations in polishing technology. Factories invest heavily in research and development, constantly improving their products to meet the demands of modern industries. This gives you a competitive edge in your work, knowing that you’re using state-of-the-art equipment that delivers superior results faster and more efficiently.

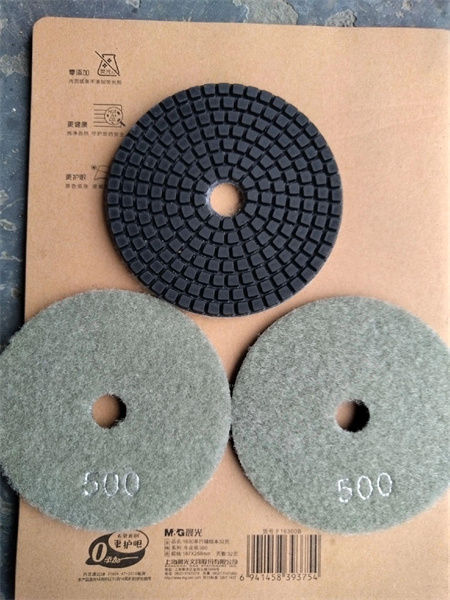

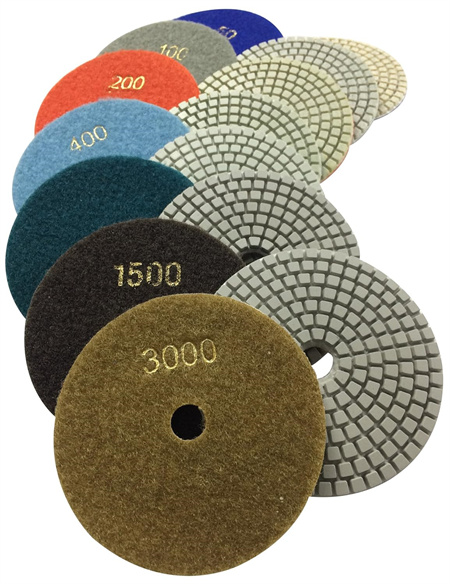

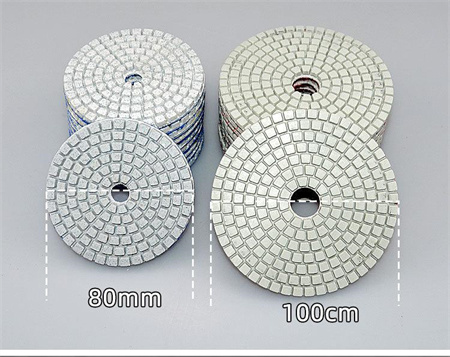

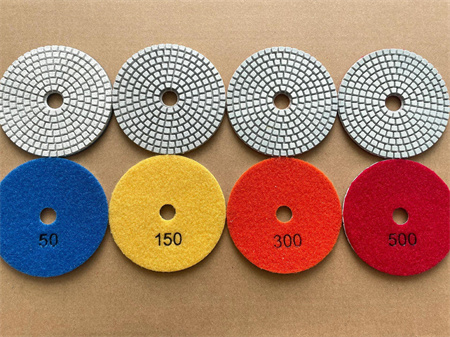

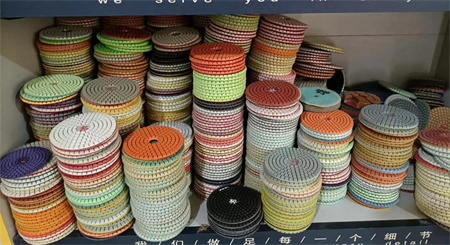

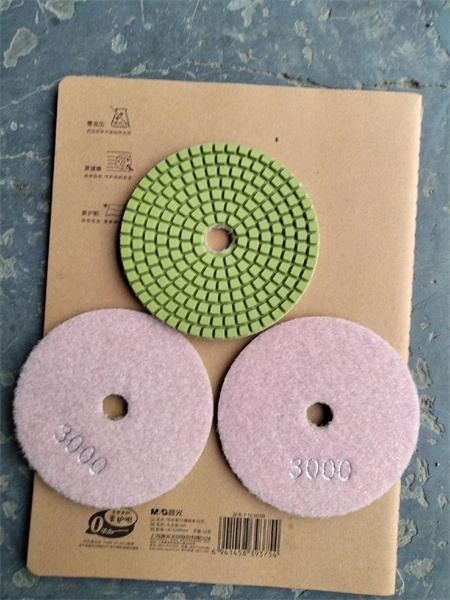

One of the most significant advantages of choosing a direct supplier is the ability to customize your order. Whether you need specific pad sizes, grit levels, or even special coatings, factories can tailor their products to suit your exact needs. This flexibility allows you to get exactly what you need, ensuring that your polishing tasks are completed with precision.

When you choose a diamond polishing pad supplier that sells directly from the factory, you also gain peace of mind knowing that you’re working with an expert. Factory suppliers have years of experience in manufacturing and distributing diamond tools, so they understand exactly what goes into making a high-quality product. They can provide you with valuable insights and advice on which pads to choose for your specific application, helping you make the best decision for your business.

Buying directly from the factory also means faster turnaround times. Without the delays caused by middlemen, your orders can be processed and shipped much quicker, allowing you to get back to work with minimal downtime.

In conclusion, sourcing your diamond polishing pads directly from a factory supplier is the smart choice for anyone looking to get the best products at the best prices. With consistent quality, customizable options, expert advice, and faster delivery, it’s a no-brainer for professionals who want to take their work to the next level.