Title: Diamond Polishing Pads for Distributors Factory in China

If you’re in the business of selling high-quality diamond polishing pads, you’re probably already aware of the huge demand for these products, particularly from industries that require precision and finesse. Whether it’s stone, marble, or concrete polishing, the need for durable, effective, and affordable diamond pads has been on the rise. As a distributor, sourcing these products from a reliable manufacturer can be the key to your success. So, why should you consider working with a factory in China for your diamond polishing pad needs?

China is home to some of the most advanced manufacturing facilities for diamond tools. The country boasts cutting-edge technology, skilled labor, and extensive experience in the production of diamond polishing pads that meet international standards. This combination of factors makes Chinese factories a prime destination for distributors looking for high-quality products at competitive prices.

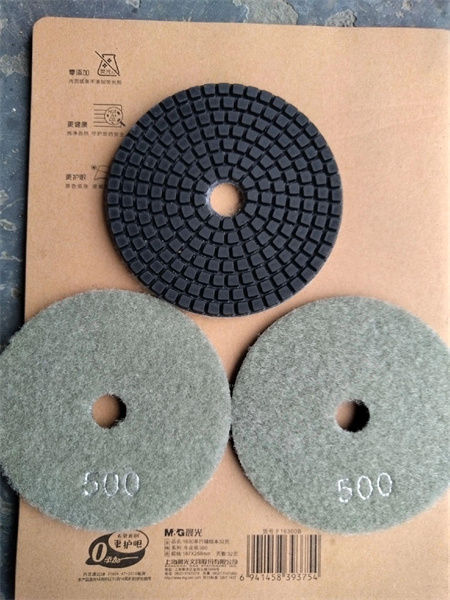

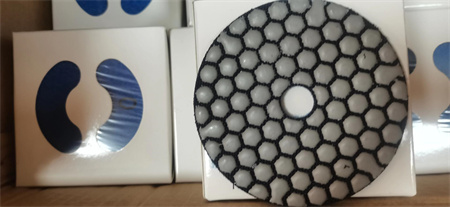

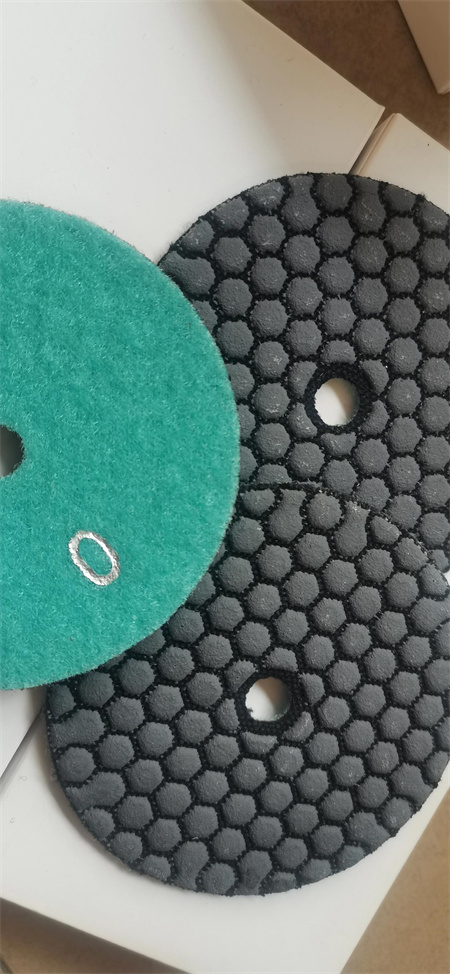

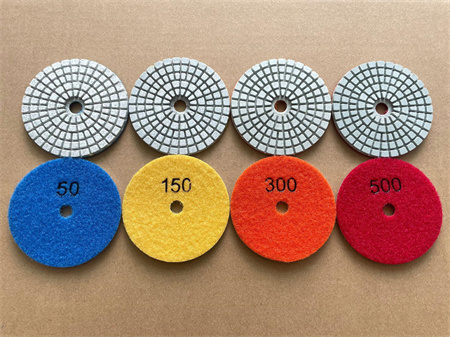

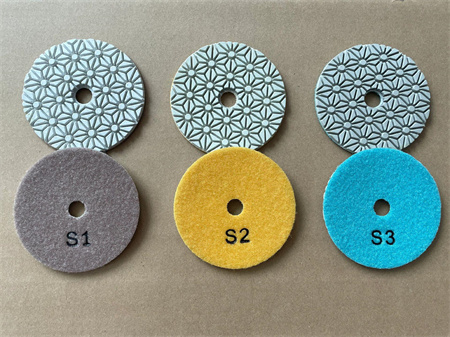

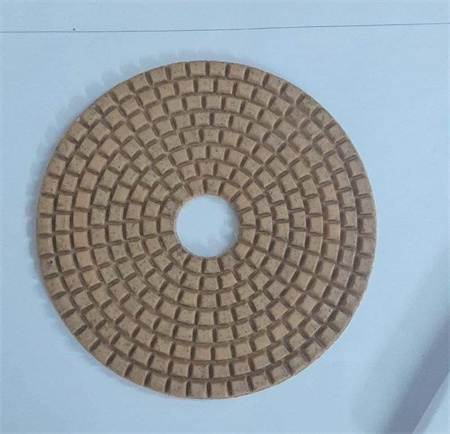

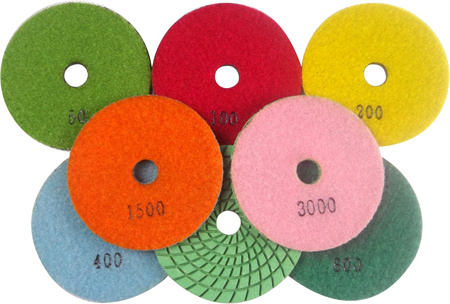

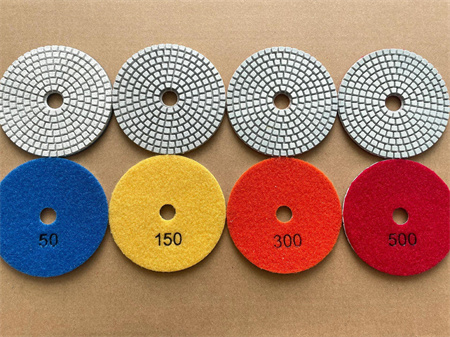

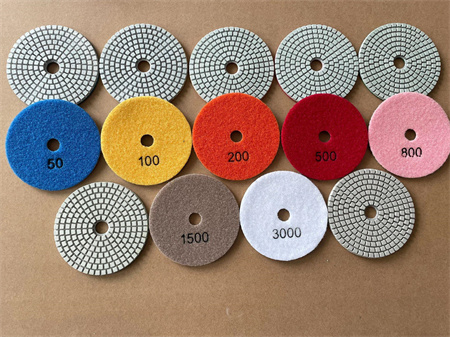

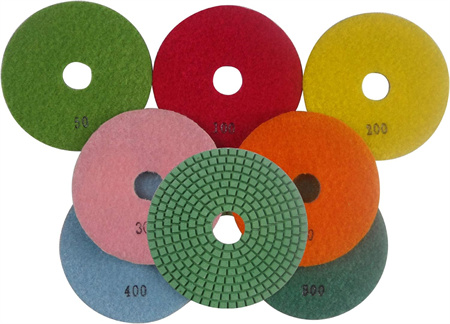

When you partner with a factory in China, you can expect a wide range of options tailored to different applications. From handheld polishing pads to larger, more industrial-sized discs, you’ll find products designed to deliver excellent results on various surfaces. What’s more, these pads are built to last, ensuring that your customers receive products that provide consistent performance over time. A key benefit is the factory’s ability to offer customized solutions. Whether your customers need a specific grit size, a special resin bond, or even a unique color for branding purposes, Chinese manufacturers are often able to accommodate such requests, making it easier for distributors to offer products that meet specific market demands.

Additionally, the speed at which Chinese factories can produce these pads makes it possible to maintain a steady supply, keeping your inventory stocked and ready to meet customer needs. Fast production turnaround, coupled with cost-effective pricing, means you can offer your customers high-end products without the hefty markup typically associated with premium brands.

A distributor looking for diamond polishing pads can also take advantage of the strong export channels in China. Factories here are well-versed in international shipping and logistics, ensuring that your orders are delivered on time and in perfect condition, no matter where you’re located.

For distributors, the benefits of sourcing diamond polishing pads from Chinese factories are clear: high-quality products, cost efficiency, customization options, and reliable delivery. With the right partnership, you can meet the growing demand for these essential tools while maintaining a competitive edge in the market.