How Diamond Pads Improve Productivity in Stone Restoration

Stone restoration is a highly specialized craft that requires precision, expertise, and the right tools. When it comes to improving the efficiency and quality of this intricate process, diamond pads have emerged as game-changers. These innovative tools not only streamline the restoration process but also enhance the overall productivity of professionals working with natural stone surfaces.

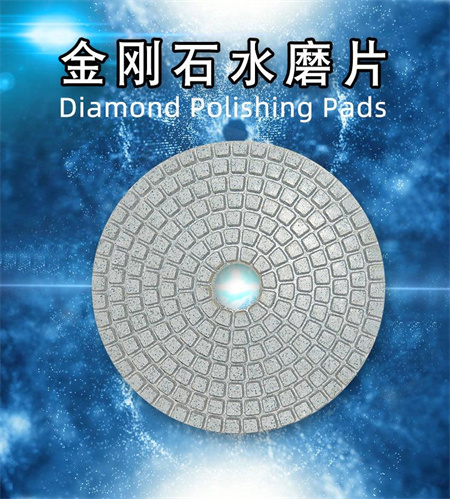

The key to their efficiency lies in the diamond grit embedded within the pads. Diamonds, being the hardest natural material on earth, offer an unparalleled cutting ability. This allows diamond pads to achieve smooth finishes more quickly than conventional sandpaper or other abrasive tools. With fewer passes required to remove scratches or imperfections, stone professionals can significantly reduce the time spent on each job.

The speed at which diamond pads work isn’t the only benefit. These tools also contribute to improved consistency and uniformity in the results. Unlike traditional abrasives, which can wear unevenly and create inconsistent finishes, diamond pads maintain their effectiveness throughout the job. Their even wear ensures a more predictable outcome, saving both time and effort in the long run. For contractors and restoration specialists, this translates into fewer mistakes and callbacks, boosting overall efficiency.

Another area where diamond pads excel is in their versatility. Depending on the type of stone and the specific task at hand, there are diamond pads available in various grits and formats. From coarse pads for heavy-duty grinding to fine pads for delicate polishing, there’s a diamond pad for nearly every stage of stone restoration. This adaptability ensures that professionals can tackle a wide range of challenges, from deep scratches and chips to achieving a glossy finish that rivals the original shine of the stone.

Moreover, diamond pads are designed to be used with wet or dry methods, providing further flexibility for different working environments. Wet polishing, for instance, helps reduce dust and heat buildup, improving both the lifespan of the tool and the comfort of the technician. For environments where water usage is restricted or where quick turnaround times are essential, dry polishing with diamond pads remains a viable option. This adaptability makes diamond pads suitable for a variety of job sites, whether indoors or outdoors, in commercial spaces or residential homes.

In addition to saving time and improving efficiency, diamond pads also play a crucial role in enhancing the overall quality of the stone restoration process. A smoother, more uniform surface means that the stone not only looks better but also lasts longer. The consistent finish achieved by diamond pads helps to preserve the integrity of the stone, reducing the likelihood of further damage or wear over time. This not only improves the appearance of the surface but also increases the longevity of the stone, making it a more valuable asset for property owners.

For businesses in the stone restoration industry, using diamond pads can lead to a significant increase in productivity. The combination of faster work, higher-quality results, and fewer tool changes can directly translate to more completed projects within a given timeframe. This boosts profits and allows restoration professionals to take on more jobs, without compromising on the quality of their work.

In conclusion, diamond pads have revolutionized the way stone restoration is performed, offering a range of benefits that directly contribute to increased productivity. Their speed, consistency, versatility, and longevity make them an indispensable tool for any professional in the stone restoration industry. By incorporating diamond pads into their workflow, restoration experts can ensure high-quality results while reducing the time and effort spent on each project. This not only improves efficiency but also helps businesses grow, creating a competitive edge in an increasingly demanding market.