How to Choose the Best Diamond Polishing Pads for Your Project

When it comes to achieving that flawless, mirror-like finish on surfaces, diamond polishing pads are indispensable tools. Whether you’re working on granite countertops, marble floors, or concrete, these pads make the polishing process more efficient and produce outstanding results. But with so many options available, how do you know which diamond polishing pad is best suited for your specific project? Here’s a guide to help you navigate the world of diamond polishing pads and find the one that fits your needs.

First, understand that not all diamond polishing pads are created equal. They vary in material, grit, size, and intended use, so knowing your project’s requirements is essential before making a decision. The right pad will not only make the job easier but will also help you achieve a smoother, higher-quality finish in less time.

Start by considering the material you’re working with. Different surfaces require different levels of abrasiveness. For harder surfaces like granite or concrete, you’ll need a more aggressive diamond polishing pad that can handle the toughness of the material. On the other hand, if you’re working with softer stones like marble or terrazzo, a pad with a finer grit would be more appropriate. The right grit size ensures you’re not overworking the surface, which can lead to uneven finishes or unnecessary wear on your tools.

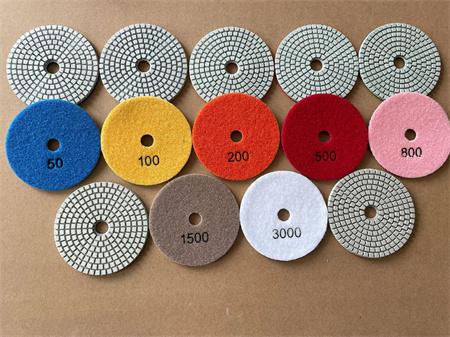

Grit size is one of the most important factors when selecting a diamond polishing pad. These pads come in a range of grits, typically from coarse to fine. The coarser the grit, the more material it removes, making it ideal for initial grinding stages when you’re dealing with rough surfaces or imperfections. As you progress to the finer grits, the pads will smooth out the surface, leaving it with a polished, high-gloss finish. A good rule of thumb is to start with a coarse grit (e.g., 50 or 100) and gradually move to finer grits, finishing with a polishing pad around 1500 or higher for that perfect shine.

Another important aspect is the type of attachment system the pad uses. Diamond polishing pads typically feature either a hook-and-loop (Velcro) system or a resin bond attachment. Velcro pads are convenient for quick changes and are ideal for smaller projects, while resin bond pads tend to offer more durability and are preferred for larger, commercial-scale jobs. Choose a pad with an attachment system that fits your grinder or polisher to ensure a seamless and efficient workflow.

Durability is another key consideration. A high-quality diamond polishing pad will last longer and deliver consistent results over the course of your project. Although you may be tempted to go for cheaper pads, it’s worth investing in premium options that feature superior diamond quality and better construction. Premium pads often use higher-grade diamonds that cut more efficiently and resist wear over time, making them more cost-effective in the long run.

Finally, don’t forget to consider the type of polisher or grinder you’re using. Some pads are optimized for use with handheld machines, while others are designed for larger, more industrial-grade machines. Make sure the diamond polishing pad you choose is compatible with your equipment to avoid issues during operation and to ensure you get the best results.

To wrap up, choosing the best diamond polishing pad for your project requires careful consideration of the material, grit size, flexibility, attachment system, and durability. By understanding the specific needs of your project and matching those requirements with the right pad, you’ll not only improve your workflow but also achieve a professional-grade finish that will leave your surfaces looking pristine.