Exploring Sustainable Materials for Diamond Pads

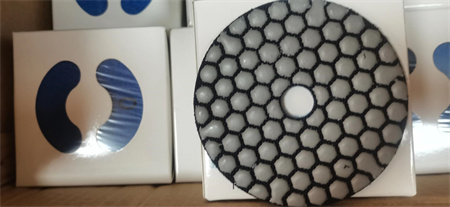

The growing demand for sustainability in the manufacturing industry is pushing companies to rethink the materials they use in everything from everyday products to specialized equipment. One area where this shift is becoming particularly important is in the production of diamond pads. Used primarily in the semiconductor industry for chemical mechanical planarization (CMP), diamond pads play a crucial role in ensuring the smoothness and flatness of silicon wafers. However, as the world becomes more environmentally conscious, manufacturers are increasingly exploring sustainable alternatives to the traditional materials used in diamond pad production.

In addition to using sustainable binders, another area of innovation lies in the diamond particles themselves. Traditionally, diamond particles used in these pads are synthetic and are often produced using high-energy processes. However, there is an increasing interest in using recycled diamonds or waste diamonds from the mining industry. These recycled diamonds are sourced from industrial by-products, such as cutting tools or jewelry manufacturing waste, and are repurposed for use in diamond pads. Not only does this practice reduce the need for mining new diamonds, but it also prevents these materials from contributing to landfill waste.

Another key consideration is the pad’s lifespan. Traditional diamond pads wear out over time, requiring frequent replacements. By developing more durable materials and improving the wear resistance of diamond pads, manufacturers can extend their lifespan, reducing the overall waste generated and the need for constant re-supply. This approach is aligned with the principles of circular economy—designing products that can be reused, repaired, or recycled to minimize waste and maximize efficiency.

Furthermore, advancements in nanotechnology and material science are offering new ways to enhance the performance of diamond pads while keeping environmental concerns in check. Nanostructured materials, for example, can offer superior performance characteristics, such as improved wear resistance and greater control over surface roughness. These innovative materials, when incorporated into diamond pads, may reduce the quantity of diamonds required in production while maintaining or even improving the pad’s effectiveness in CMP applications.

The shift toward sustainable materials in diamond pads not only addresses environmental concerns but also responds to a growing demand from semiconductor manufacturers who are under increasing pressure to meet sustainability goals. Many leading technology companies are setting ambitious targets to reduce their carbon footprint, and the materials used in the manufacturing of semiconductors play a key role in achieving these goals. By exploring sustainable materials for diamond pads, manufacturers can help their customers meet these objectives while also advancing their own sustainability efforts.

In conclusion, the push for sustainability in the semiconductor industry is driving significant innovation in materials science, especially in the realm of diamond pads. Whether it’s the use of biodegradable resins, the recycling of diamonds, or the development of more durable and efficient materials, the future of diamond pad production looks promising. By embracing these sustainable practices, manufacturers not only contribute to a greener future but also set the stage for a more efficient and responsible approach to semiconductor manufacturing. As the industry continues to evolve, the integration of sustainable materials into diamond pad production will likely become a key factor in shaping the future of this essential technology.