How to Repair Minor Damage to Diamond Pads

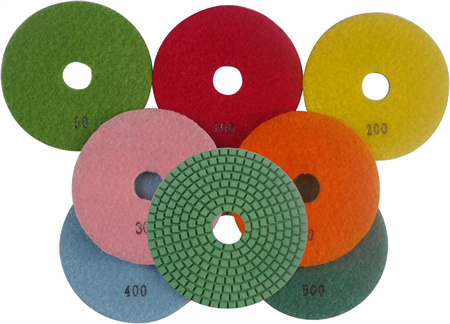

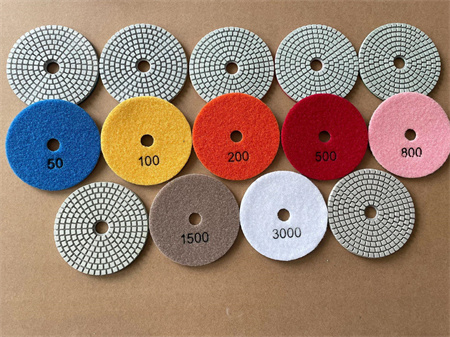

Diamond pads are an essential tool in many industries, from automotive repair to flooring and polishing. They are prized for their durability and the precision they bring to tasks like grinding, polishing, and surface preparation. However, over time, even the toughest diamond pads can experience some wear and tear, whether from regular use or accidental mishaps. While these minor damages might seem intimidating, repairing them is often easier than it looks. With the right approach, you can extend the life of your diamond pads and restore their effectiveness.

Reconditioning the Surface

One of the easiest ways to repair minor damage is by reconditioning the surface of the diamond pad. Over time, diamond pads can accumulate debris, resin, or residue that interferes with their performance. Cleaning the surface thoroughly is essential before performing any kind of repair. You can use a soft brush or a cloth to wipe off the pad. For more stubborn residue, you might need to use a mild solvent or a specific cleaning agent designed for polishing pads. After cleaning, let the pad dry completely before proceeding.

Once the pad is clean, you can use a diamond sharpening stone or a diamond dressing tool to restore the surface. This process involves lightly resurfacing the pad, which can help expose fresh diamond particles, improving its cutting or polishing ability. Just be sure to use the dressing tool gently—too much pressure can cause further damage. This technique is ideal for pads that still have a decent amount of diamond grit left but need a bit of refreshing to keep them effective.

Applying New Resin or Bonding Material

If the pad has lost a significant number of its diamond particles, you can consider applying new resin or bonding material to the damaged areas. There are specialized repair kits available that contain bonding compounds specifically designed for diamond pads. These kits usually include the resin, a hardening agent, and a brush or spatula for applying it to the pad.

To use the kit, mix the resin and hardening agent according to the manufacturer’s instructions, and then carefully apply the mixture to the worn or damaged sections of the pad. After the resin is applied, let it cure for the time recommended by the manufacturer—this usually takes anywhere from a few hours to overnight. Once cured, the repaired sections will be ready for use, and your diamond pad will have a new lease on life.

Preventative Measures for Future Damage

Repairing minor damage is one thing, but preventing it from happening again is another matter entirely. Taking some simple steps to care for your diamond pads can help extend their lifespan and keep them performing at their best. Regularly cleaning your pads, using them at the correct pressure, and avoiding harsh chemicals or materials that could cause undue wear will go a long way in preventing damage.

Finally, proper storage is essential. After using your diamond pads, make sure they’re stored in a clean, dry place. Avoid storing them in direct sunlight or in areas with high humidity, as these conditions can cause the resin to break down prematurely.

When to Replace the Pad

Even with the best care and repair methods, there comes a time when it’s simply not worth trying to fix a severely damaged diamond pad anymore. If the pad has significant structural damage or if the diamonds have worn down beyond repair, it may be time to replace it. Using a worn-out pad can lead to subpar results and potentially damage the surface you’re working on. In these cases, it’s best to invest in a new pad to ensure top-quality performance.

Repairing minor damage to diamond pads is a simple process that can save you money and extend the life of your equipment. Whether you’re reconditioning the surface, applying a new bonding material, or simply keeping the pads clean, taking action quickly can prevent further wear and tear. With a little care, your diamond pads will continue to work efficiently and effectively for many projects to come.