The Role of Diamond Pads in Large-Scale Stone Installations

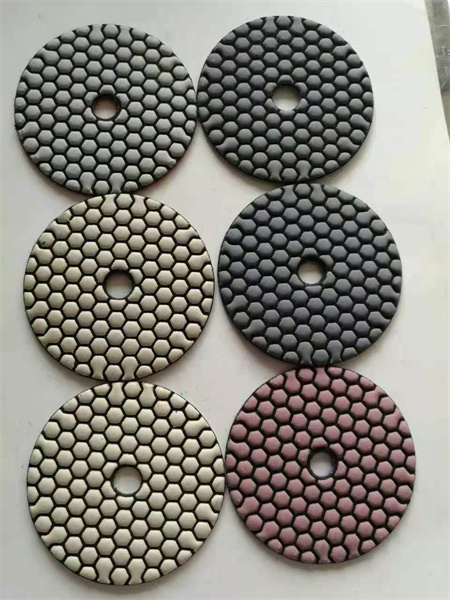

Diamond pads, made of a composite material with diamond particles embedded in a resin or metal bond, are essential for achieving the smooth, glossy finish that many stone applications demand. They’re used to refine the stone’s surface during the polishing process, whether for granite, marble, or concrete. But what makes them indispensable in large-scale installations is their ability to handle the toughest tasks with precision and efficiency.

One of the primary reasons diamond pads are so valuable in large-scale projects is their durability. Stone surfaces, especially those used in commercial and industrial applications, endure heavy traffic, wear, and even the elements. Polishing and finishing these surfaces can be labor-intensive and time-consuming, especially when dealing with vast expanses of stone. Diamond pads, however, offer a consistent, high-quality finish over large areas without the need for constant replacement. The diamond particles are hard and resistant to wear, which means that the pads can maintain their effectiveness over thousands of square feet of stone.

Moreover, the versatility of diamond pads is another reason they are essential for large-scale stone installations. They come in a range of grits, from coarse to ultra-fine, allowing workers to tailor the polishing process to the specific needs of the stone surface. Coarse pads are ideal for smoothing out rough stone or removing scratches and imperfections, while finer pads are perfect for creating that glass-like finish that’s so coveted in modern design. This level of control over the surface finish makes diamond pads indispensable, whether the goal is to create a rustic, honed texture or a polished, shiny surface.

Another key advantage of diamond pads is their efficiency. Large-scale stone installations can involve hundreds, if not thousands, of square feet of stone. In such projects, time is often a limiting factor. With traditional polishing methods, the process could take days or even weeks. However, diamond pads significantly speed up the process, allowing professionals to achieve a high-quality finish in a fraction of the time. This efficiency translates into lower labor costs and faster project completion, making it a win-win for contractors, architects, and clients alike.

Beyond their speed and durability, diamond pads also offer a level of consistency that is difficult to achieve with other tools. Unlike traditional abrasives, which can vary in quality and performance, diamond pads are engineered for precision. The uniform distribution of diamond particles ensures that each pad produces the same result, providing a consistent finish throughout the entire installation. This is especially important in large-scale projects, where uniformity is key to achieving a professional appearance.

In large-scale projects, the need for safety and environmental considerations also plays a role in the choice of tools. Diamond pads typically produce less dust and waste compared to traditional methods, making them a more environmentally friendly option. With an increasing emphasis on green building practices, contractors are drawn to the efficiency and cleanliness that diamond pads offer. Furthermore, the reduced need for harsh chemicals or polishing agents makes them safer for workers, reducing exposure to potentially harmful substances.

In conclusion, diamond pads are an indispensable tool in the world of large-scale stone installations. Their durability, versatility, speed, and efficiency have made them the go-to choice for professionals in the stone industry. Whether the project is commercial, residential, or public, diamond pads provide the means to achieve a flawless finish that enhances the natural beauty of stone. In an industry where quality and precision are paramount, diamond pads are the unsung heroes that make large-scale stone installations not only possible but also truly spectacular.