Using Diamond Pads for Multi-Surface Polishing in One Job

When it comes to achieving a flawless, smooth finish on various surfaces, diamond polishing pads have become an indispensable tool for both professionals and DIY enthusiasts. These pads are a game-changer for anyone looking to tackle multiple surfaces with efficiency and precision, whether it’s marble, concrete, granite, or even terrazzo. The versatility and durability of diamond pads allow for a high-quality, polished finish across different materials, all with a single set of tools.

In the world of surface polishing, the right equipment can make all the difference. Diamond pads stand out for their exceptional performance, and here’s why they’re gaining popularity among those who demand perfection in their work.

The Power of Diamond Abrasives

At the heart of diamond polishing pads is, of course, the diamond itself. Known for its unmatched hardness, diamond allows these pads to handle even the most difficult surfaces with ease. Whether you’re working with soft stones like marble or harder materials like granite, the diamond abrasives provide a consistent, scratch-free finish without excessive wear on the pad itself.

What makes diamond pads particularly appealing is their ability to handle multiple surface types in one job. Many polishing projects involve a variety of materials, which can be time-consuming and costly if different tools and abrasives are required for each. Diamond pads eliminate the need for swapping out tools by offering a one-size-fits-all solution for different surfaces. This translates into significant time and cost savings for professionals who often deal with diverse projects.

Versatility Across Materials

A single diamond polishing pad can be used across a range of surfaces, including natural stones like granite, marble, and limestone, as well as man-made materials like terrazzo and concrete. This multi-surface capability is not only a matter of convenience but also of consistency. Many traditional polishing pads require specialized pads for each material, which can result in uneven results, especially when transitioning from one surface to another. With diamond pads, however, the process remains smooth and uniform, ensuring that all materials receive the same high-quality finish.

For instance, when polishing concrete floors, diamond pads efficiently remove surface imperfections, honing the concrete to a glossy sheen without leaving behind visible scratches. The same pad can be used to bring out the deep shine of a marble countertop or smooth out the rough surface of granite. This flexibility allows users to achieve a professional-grade polish across different surfaces with a single tool, cutting down on the number of pads and steps required for the job.

In the past, polishing different surfaces often meant changing between multiple types of abrasives or pads—each suited to a particular material. This time-consuming process not only increased labor costs but also slowed down the overall project timeline. By using diamond pads that are designed for use on a variety of surfaces, professionals can dramatically reduce the time spent switching between tools.

Long-Lasting Performance

Diamond polishing pads are built to last. Unlike traditional sandpaper or polishing pads, which degrade quickly under pressure, diamond pads maintain their shape and effectiveness even after extensive use. The durability of these pads makes them a wise investment for anyone involved in surface polishing.

Additionally, the uniformity of the abrasive particles embedded within the pad means that the polishing action remains consistent throughout the pad’s lifespan. This ensures that each surface receives the same high-quality finish from the start of the job to the finish, making the process more predictable and reliable.

How to Get the Best Results with Diamond Pads

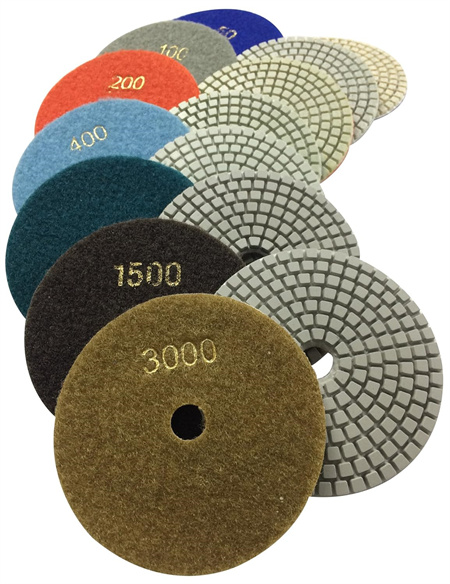

While diamond pads are incredibly versatile, it’s essential to use them correctly to maximize their effectiveness. First, ensure you’re using the right grit for the job—coarse grits are ideal for aggressive grinding and removing heavy imperfections, while finer grits will provide that mirror-like finish. Additionally, always use the pads with the appropriate equipment, such as polishing machines or angle grinders, to ensure optimal results.

The Bottom Line

Diamond pads have revolutionized the way we approach multi-surface polishing. With their ability to work across different materials without sacrificing quality or consistency, they offer unmatched versatility, efficiency, and durability. Whether you’re a professional contractor, a stone fabricator, or simply someone who enjoys DIY projects, investing in diamond polishing pads will not only save you time and money but also help you achieve that perfect, glossy finish on a variety of surfaces. If you’re looking for a way to streamline your polishing process and improve your results, diamond pads are definitely the way to go.