Popular Pad Sizes in European Stone Polishing Businesses

In the world of stone polishing, the choice of pad size plays a crucial role in determining the quality of the final finish. Whether working with marble, granite, or concrete, stone polishing businesses in Europe have diverse needs, each shaped by the type of stone being worked on and the scale of operations. As the demand for polished stone surfaces grows across residential, commercial, and industrial sectors, understanding the popular pad sizes used in these businesses becomes essential.

The Versatility of Medium-Sized Pads

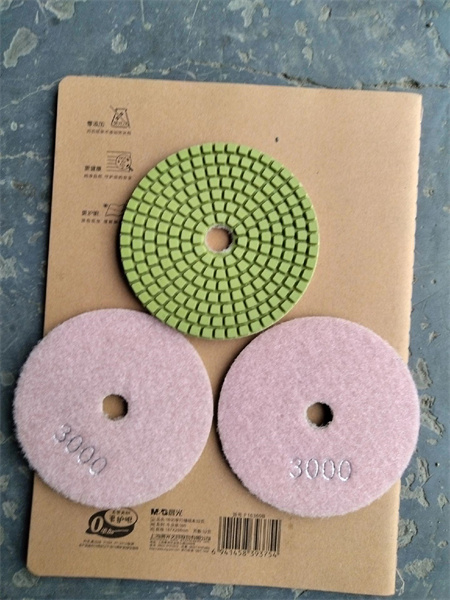

Among the most popular sizes used in the European stone polishing industry are medium-sized pads, typically ranging from 4 to 6 inches in diameter. These pads strike the ideal balance between control and coverage, making them a favorite for polishing countertops, flooring, and smaller slabs. With their manageable size, they provide more precision than larger pads, which can be essential when working on intricate designs or smaller, custom projects.

The versatility of medium-sized pads also lies in their compatibility with different polishing machines, including both hand-held devices and floor grinders. This adaptability is particularly valuable in the European market, where businesses often handle a variety of jobs—some requiring high-speed polishing for large surfaces, and others demanding the careful attention required for delicate, high-end marble work.

Larger Pads for Industrial-Scale Projects

On the other end of the spectrum, large pads, typically between 7 and 12 inches, are essential for businesses that focus on industrial-scale projects. Large pads allow for faster, more efficient polishing of large stone surfaces, such as flooring in public spaces, large countertops, or stone slabs used for architectural facades. These pads cover more area in a single pass, making them ideal for projects that demand speed without sacrificing the finish quality.

One of the reasons large pads are so popular among European businesses involved in large-scale stone projects is their ability to handle the rougher work that is often part of the initial stages of the polishing process. For instance, after the initial grinding, larger pads are effective in removing deep scratches and imperfections. This is especially important in commercial settings where time is of the essence, and the workflow needs to be as efficient as possible.

Smaller Pads for Precision and Detailing

While larger pads are used for efficiency, smaller pads—usually ranging from 3 to 4 inches—are gaining popularity in the European stone polishing industry for tasks that require precision. These pads are commonly used for edge work, polishing small surfaces, or detailing intricate patterns on stone slabs. Smaller pads are ideal for those working on high-end projects where every detail counts, such as custom-designed marble countertops, mosaic floors, and decorative stone elements.

European businesses that specialize in bespoke stone designs often opt for smaller pads to ensure that every nook and cranny is perfectly polished. This size also allows for better control when working on textured stone surfaces, ensuring that the final finish meets the client’s exact specifications. The growing trend of luxurious, bespoke stone finishes across Europe has led to a greater demand for these more precise, smaller pads.

The Role of Flexibility in Pad Size Selection

Another important consideration for stone polishing businesses in Europe is the flexibility that different pad sizes offer. With varying stone types and diverse customer needs, having a range of pad sizes ensures that businesses can meet the specific requirements of each job. For instance, businesses might switch between larger pads for the main polishing job and smaller pads to finish off the edges and corners, giving their work a polished, professional appearance.

Moreover, many stone polishing pads come in a range of grits, from coarse to fine, which complements the pad size and allows businesses to adapt to different stages of the polishing process. Whether they are working on rough granite or the more delicate, porous surfaces of limestone, the combination of pad size and grit ensures that the stone is polished to perfection.

Choosing the Right Pad for the Job

Whether polishing small marble tiles, large granite slabs, or intricate stone sculptures, stone polishing businesses in Europe are increasingly investing in a range of pad sizes to meet the diverse demands of their clients. From medium-sized pads that offer versatility and control to large pads that enhance productivity on larger surfaces, the right pad size can make all the difference in the success of a project.

As the stone polishing industry continues to evolve, one thing remains clear: pad size is more than just a technical choice—it’s a fundamental element in achieving the high-quality finishes that clients expect. European stone polishing businesses that keep up with trends and understand the varying needs of their clients will continue to lead the way in producing beautiful, polished stone surfaces that define the region’s architectural and design landscapes.