Dust is an inevitable byproduct of many polishing processes, and when it comes to using dry polishing pads, keeping the dust under control can feel like a never-ending challenge. But with a few smart techniques and the right approach, you can significantly reduce the amount of dust generated during dry polishing. Whether you’re working on floors, countertops, or other surfaces, these practical tips will help you improve air quality, reduce cleanup time, and protect both your equipment and health.

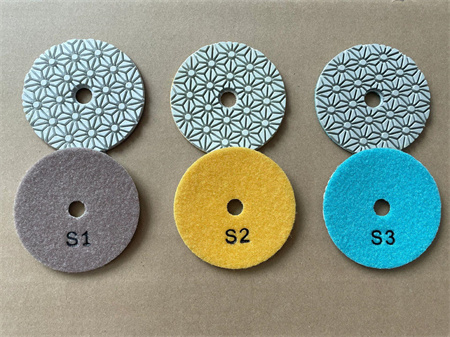

A key aspect to consider is the grit size of your polishing pad. Generally, finer grits tend to produce less dust because they generate less friction. However, if you’re working on tough materials or need to remove more material quickly, a coarser grit might be necessary. When using a coarser pad, be mindful of the speed and pressure you apply, as they can directly influence how much dust is created. Often, polishing with a light touch and slow speed helps reduce the amount of dust kicked up, even with a more aggressive pad.

The environment where you are working also plays a critical role in dust control. If possible, work in a well-ventilated area. Good airflow helps prevent dust from accumulating and spreading through the air, especially in smaller, closed-off spaces. Open windows or use exhaust fans to keep the air moving. If you’re polishing in a smaller area without natural ventilation, consider using a vacuum system designed for dry polishing. These vacuums attach directly to your polishing equipment and work by sucking up dust as you polish. This not only helps keep the workspace cleaner but also makes the process far more pleasant by reducing airborne particles.

Another tip for reducing dust is to frequently clean your pads during use. Dust buildup on the surface of the polishing pad can quickly turn into a source of more dust. By periodically removing the dust from the pad, you ensure that it works efficiently without becoming overloaded. A simple tap or brushing of the pad will help, but make sure to check the manufacturer’s instructions to ensure you’re not damaging the pad in the process.

It’s also important to keep the surface you’re working on in mind. Dry polishing pads are best used on surfaces that are clean and free from excess debris. Dirt or small stones on the surface can create additional dust when they come into contact with the pad. Before beginning the polishing process, always clean the surface thoroughly to minimize this risk. A quick sweep or vacuum of the area is a small effort that can make a big difference in how much dust gets kicked up.

Don’t forget the importance of wearing protective gear while polishing. Even with all these tips in place, a small amount of dust may still be generated, and it’s always better to be safe than sorry. Dust masks or respirators are essential, especially when working in environments with limited ventilation. Eye protection is also a must, as dust particles can irritate or injure the eyes.

By following these tips, you’ll be well on your way to reducing dust when using dry polishing pads. Dust-free polishing not only leads to cleaner air and a healthier workspace but also enhances the quality of your results. It’s a small effort with big rewards, both for you and your environment.