Temperature Tolerance of Diamond Polishing Pads

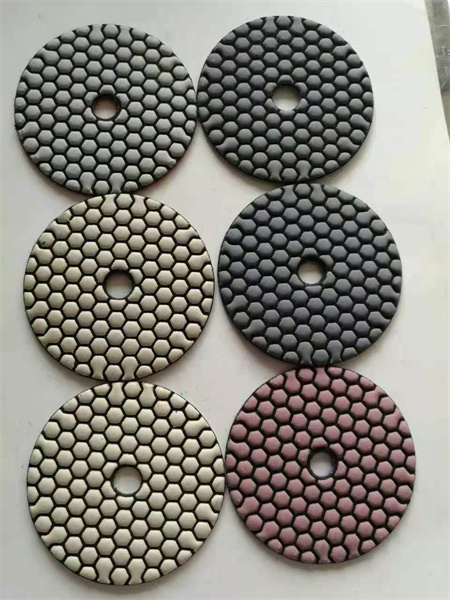

When it comes to precision polishing, especially in industries like stone, ceramics, and semiconductor manufacturing, the equipment used must be reliable under a variety of conditions. One critical aspect that often goes unnoticed is the temperature tolerance of the diamond polishing pads. These pads are vital in achieving a smooth, flawless finish, but their performance can be severely impacted by high temperatures. Understanding how temperature affects the diamond pads’ durability and efficiency is crucial for anyone using these pads in high-intensity applications.

Diamond polishing pads are designed to deliver exceptional performance, but like any tool, they have their limits. Temperature fluctuations are one of the biggest challenges these pads face during heavy-duty polishing operations. As the surface being polished heats up due to friction, the pad itself also absorbs heat, which can lead to degradation of the resin bond, a crucial element in holding the diamond abrasives in place.

For example, when polishing materials that generate a significant amount of heat, such as granite or concrete, temperatures on the pad surface can rise significantly. In some cases, these temperatures can easily surpass the recommended operating range for standard diamond pads. This often leads to a reduction in the lifespan of the pad and affects its performance, resulting in a less efficient polishing process and a subpar finish.

The resin bond, which holds the diamond grit, plays a key role in maintaining the pad’s integrity. High temperatures can soften or even melt the resin, which weakens the bond between the diamonds and the pad. When the bond weakens, the diamonds can become loose or dislodged, causing uneven polishing, reduced abrasiveness, and eventually the need for more frequent replacements. This increases the cost of operation and can slow down the overall workflow.

Temperature tolerance varies across different types of diamond pads. While some pads are designed for use at higher temperatures, others are best suited for more moderate conditions. It’s essential for users to select the right pad based on the temperature conditions they anticipate during the polishing process. For example, some high-quality diamond pads are engineered with specialized resins that can withstand higher temperatures, making them ideal for applications where excessive heat is a concern.

For professionals working with particularly heat-sensitive materials or in high-temperature environments, diamond polishing pads with enhanced thermal stability are the best choice. These pads are made with advanced bonding materials and diamond structures that can endure heat without losing performance. Pads with a metal bond, for instance, tend to have better heat resistance than those with resin bonds, making them suitable for polishing hard materials that generate high frictional heat.

In some cases, alternating between different pads designed for various temperature conditions may be necessary, especially in large-scale operations where temperature changes are frequent and unpredictable. By using the appropriate pad for the right temperature, operators can ensure that the polishing process remains efficient and cost-effective.

The temperature tolerance of diamond polishing pads is more than just a technical specification; it’s a determining factor in achieving the perfect polished finish. Understanding how heat impacts these tools allows professionals to make informed decisions, whether it’s selecting the best pad for their needs or implementing strategies to minimize heat buildup. With the right choice and proper care, diamond polishing pads can continue to perform at their best, delivering flawless results for years to come.