Stone Fabricators’ Guide to Diamond Pad Selection

When it comes to stone fabrication, achieving the perfect finish is what separates a good job from a great one. Whether you’re working with granite, marble, or quartz, diamond pads are an essential tool for achieving the high-quality surface that customers expect. Choosing the right diamond pad can make all the difference, not just in the outcome, but also in the efficiency and lifespan of your tools. Here’s everything you need to know to navigate the process and select the best diamond pads for your stone fabrication needs.

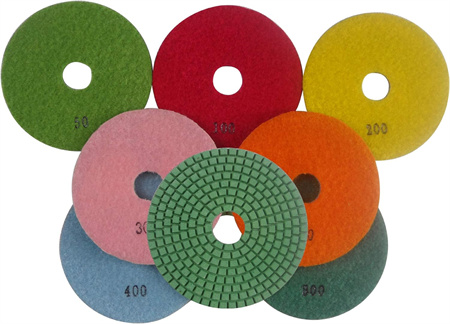

First off, not all diamond pads are created equal. They come in different grits, types, and bonds, each designed for specific stages of the polishing process. If you’re just starting with stone fabrication or are looking to upgrade your equipment, it’s important to understand what each type of pad offers.

Understanding the bonding process of diamond pads is just as crucial. The bond refers to the matrix that holds the diamonds in place. There are different types of bonds available, such as resin, metal, and ceramic, and each one is suited for different applications. Resin bonds, for example, are ideal for softer stones like marble and quartz. They provide a smooth finish but may wear out quicker when used on harder stones like granite. On the other hand, metal-bonded pads are designed for tougher materials and are perfect for aggressive grinding or heavy-duty tasks.

For fabricators who work with a wide range of stone types, versatility in pad selection is critical. If you work primarily with harder stones like granite, you’ll want pads with a stronger bond—something that will last longer and offer greater wear resistance. For softer stones, a pad with a more flexible bond may be preferable, as it allows for a smoother finish without excessive wear.

Another important factor in diamond pad selection is the type of machine you’re using. The method of attachment varies between wet and dry pads, so it’s essential to know which type of equipment you have. Wet pads require water to cool the tool and prevent overheating, which is essential for maintaining the integrity of both the pad and the stone. Dry pads, on the other hand, are used for polishing in dry conditions. While they are more convenient for certain setups, they tend to wear out more quickly and may not provide the same level of smoothness as their wet counterparts.

Durability is another key consideration. High-quality diamond pads may cost more upfront, but they will save you money in the long run by lasting longer and delivering better results. Inferior pads may wear out quickly, requiring more frequent replacements, which can add up over time. Look for pads from reputable manufacturers known for their durability and consistency, and always read reviews or seek recommendations from other professionals in the field.

Ultimately, selecting the right diamond pad boils down to understanding your specific needs. Are you working on a high-volume project that demands speed, or are you crafting a luxury countertop where every detail matters? Are you dealing with a variety of stone types, or is your focus solely on granite? By taking the time to assess your materials, machines, and project goals, you’ll be able to make an informed decision and select the right diamond pads for the job.

In conclusion, stone fabrication is as much about the tools you use as it is about the skill you bring to the work. Diamond pads play an integral role in ensuring a flawless finish, so it’s worth investing the time and effort to choose the right ones. From coarse grinding to fine polishing, the right diamond pad will help you achieve the best results while extending the life of your tools and improving the efficiency of your work. The right pad, used at the right time, makes all the difference in bringing your stone projects to life.