Market-Specific Grit Preferences in Diamond Pads

In the world of diamond pads, one thing becomes abundantly clear: grit preferences aren’t universal. Whether you’re working with concrete, granite, marble, or another stone material, the grit size and the type of diamond pad you choose can make or break the results. Understanding these market-specific preferences is key to achieving the perfect finish for any job.

When it comes to the diamond pad industry, grit size isn’t just a number on a scale. It’s a fundamental part of the process that dictates everything from how smooth the surface becomes to how much wear and tear the pad itself will endure. But the choice of grit isn’t just about the material you’re working with – it’s influenced by the region, the type of equipment, and the specific demands of the market. A pad that works wonders in one part of the world might not be the best fit in another.

On the other hand, the European market often leans toward finer grits, especially when dealing with materials like marble or granite. European professionals may prioritize precision and a smoother finish, which is why grit sizes from 100 to 400 are more commonly used in these regions. Polishing processes in Europe are usually slower and more methodical. The preference for finer grits reflects the importance of achieving a high-quality, aesthetically pleasing finish. In fact, the use of finer grit pads helps to prevent the appearance of scratches or marks that might otherwise appear on soft stones, which is crucial for both residential and commercial applications.

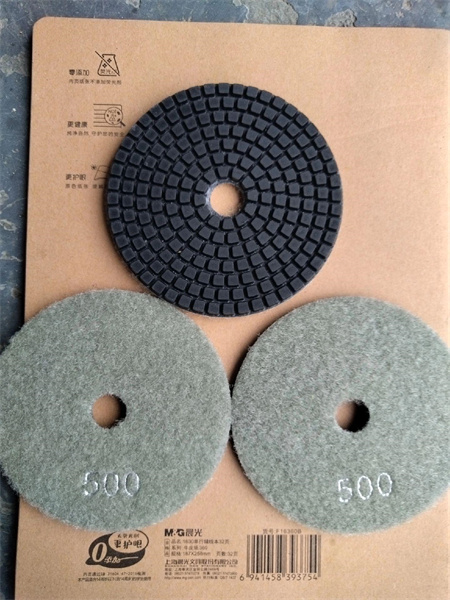

The Asian market, particularly in countries like China and Japan, often deals with a different set of expectations. While the material selection is similar to Europe and North America, the demands of speed and cost-efficiency drive the grit preferences. Workers in these regions might start with a medium grit pad (around 50 or 60) for initial grinding and progress to finer grits as the process moves forward. However, there’s also a growing trend of using ultra-fine grits for the final polishing stages, especially for premium materials or high-end projects. As the market for luxury stone finishes grows, the demand for diamond pads that can deliver a mirror-like shine is on the rise.

However, regardless of the market, one consistent trend across all regions is the growing demand for versatility. Professionals across the globe are seeking diamond pads that can handle multiple surfaces with ease. Whether you’re working with natural stone, concrete, or terrazzo, the ability to switch between different grit sizes without compromising performance is a significant selling point. As technology continues to evolve, manufacturers are responding to this need by developing diamond pads that are not only durable but also capable of providing consistent results across a range of materials and grit requirements.

A key factor that continues to shape market-specific grit preferences is the growing focus on sustainability. As industries strive to reduce their environmental footprint, the demand for long-lasting, efficient diamond pads has grown. Pads with higher durability mean fewer replacements and less waste, which is a priority for many companies. Additionally, the shift towards eco-friendly production processes is influencing grit selection, with more companies opting for pads made from recycled or sustainable materials.