How to Choose the Right Polishing Pad Manufacturer

Choosing the right polishing pad manufacturer is more than just a purchasing decision—it’s a strategic move that can significantly impact the quality of your work, efficiency, and overall business success. Whether you’re a professional in the automotive, manufacturing, or furniture industry, the polishing pad you choose can make a huge difference in the final finish of your product. So, how do you find the right manufacturer to meet your specific needs?

It starts with understanding what makes a good polishing pad. At its core, a polishing pad must be durable, effective, and suited to the specific application at hand. But behind these basic requirements lies a host of factors that differentiate one manufacturer from another. Let’s break down what to consider when making this important choice.

1. Quality Control Standards

A reputable polishing pad manufacturer will always prioritize quality. Quality control should be a non-negotiable aspect of their production process. If a manufacturer is cutting corners or lacks a consistent quality control system, your pads might suffer from irregularities—resulting in inconsistent polishing results or even damage to the surfaces you’re working on. It’s essential to choose a manufacturer that adheres to high standards and can demonstrate their commitment to quality. Look for companies with clear, reliable certifications and evidence of rigorous testing protocols.

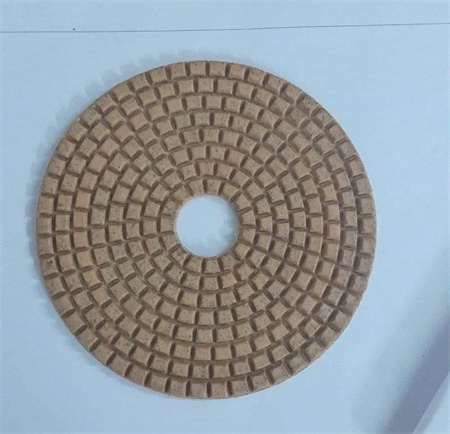

The right manufacturer will ensure that each polishing pad is free from defects, offering uniform texture and thickness. This is crucial not just for the final appearance of your work but for the longevity and efficiency of the pads themselves.

2. Material Selection and Technology

Polishing pads are made from various materials like foam, wool, microfiber, and more. Each material has its specific benefits depending on the application, whether it’s for cutting, polishing, or finishing. A great manufacturer should have the expertise to recommend the right material for your needs, offering a range of options that cater to different tasks, from light polishing to heavy-duty cutting.

Some manufacturers also invest in cutting-edge technologies, like advanced foaming processes or smart design features, which can significantly enhance the performance of their pads. The latest innovations could include features such as heat resistance, better cushioning, or longer durability. So, pay attention to the materials and technologies the manufacturer uses—it’s often a reflection of how much effort they put into developing top-tier products.

3. Customization Options

In many industries, one size does not fit all. Your business may have specific needs that require tailored polishing pads. Whether you’re looking for a particular size, shape, or abrasive type, customization can play a crucial role in your purchasing decision. Some manufacturers offer bespoke solutions, allowing you to order pads that fit your unique specifications, ensuring they work perfectly with your machinery and production process.

4. Customer Service and Support

A manufacturer’s level of customer service is often an overlooked but essential aspect of your decision-making process. Working with a responsive and knowledgeable team will save you time, help resolve issues, and provide guidance as needed. Whether it’s technical support for new product setups or assistance with choosing the right pad for a particular job, a manufacturer with excellent customer service can be invaluable.

Look for manufacturers who offer clear communication channels, offer comprehensive product documentation, and can provide timely after-sales support. A good manufacturer should be willing to address any concerns and work with you to improve your polishing process over time.

5. Reputation and Reviews

One of the best ways to gauge the reliability and quality of a manufacturer is by checking their reputation. Customer reviews, testimonials, and case studies can give you valuable insight into how other businesses view the manufacturer’s products. A good manufacturer will have a track record of satisfied clients who can speak to the reliability, durability, and performance of their polishing pads.

Take time to research online reviews and perhaps even speak to current customers about their experiences. Pay close attention to how the manufacturer handled challenges, their response times, and their willingness to stand behind their products. A manufacturer who consistently delivers high-quality products and support will have a solid reputation in the industry.

6. Price vs. Value

Price is always a consideration when choosing a supplier, but it should never be the deciding factor alone. Often, cheaper pads come with compromises in quality, durability, or performance, leading to increased costs in the long run due to premature wear and tear or the need for more frequent replacements.

Instead of focusing solely on price, focus on value. A high-quality polishing pad may have a higher upfront cost but could save you money over time by improving efficiency, reducing product defects, and decreasing downtime. A reliable manufacturer who delivers high-performing products will often provide the best return on investment.

7. Delivery Time and Availability

Lastly, consider the lead time and availability of the manufacturer. You don’t want to be left in the lurch waiting for critical supplies. A manufacturer with efficient production and shipping timelines will help keep your operation running smoothly without costly delays. Make sure they can meet your demand volume without sacrificing quality.

A supplier that offers fast delivery and easy reordering options is a valuable partner who can keep your business moving forward, especially during busy seasons.

Conclusion

Choosing the right polishing pad manufacturer is about much more than just picking a supplier—it’s about forging a partnership that can drive your business forward. Focus on quality, technology, customer service, and reputation. Don’t be afraid to ask questions, request samples, and dive deep into a manufacturer’s offerings. With the right manufacturer by your side, your polishing tasks will become more efficient, effective, and ultimately, more successful.